How to weld polypropylene pipes. selection by type of

Polypropylene, which appeared on the market relatively recently, quickly won the ardent sympathies of plumbers and their customers, first of all, the owners of private houses. We have to find out by what signs it is worth choosing and how to weld the polypropylene pipes. The article is focused primarily on beginners who are just eyeing the unusual material.

Selection

Let's start with the procurement. So, we are in the store; On the shop window there are several types of polypropylene, differing in the price per meter and some incomprehensible symbols in the marking. What to look at first?

Polymer type

- If you pick up pipes for cold water supply, then you can pay attention to products with PPH marking.

- For hot water and heating is suitable polypropylene labeled PPB and PPR (PPRC).

Note: we intentionally do not give the full names of the corresponding homo-and copolymers. For the reader who selects material for repairs in an apartment or house, this information is clearly redundant.

Operating pressure

Its nominal value in kgf / cm2 (atmospheres) is indicated after the letters PN in the marking. It varies from 10 to 25 atmospheres. It would seem that the upper value is obviously redundant, because the pressure in the water mains and heating mains, not to mention autonomous systems, does not exceed 6-7 kgf / cm2.

However, there are two nuances:

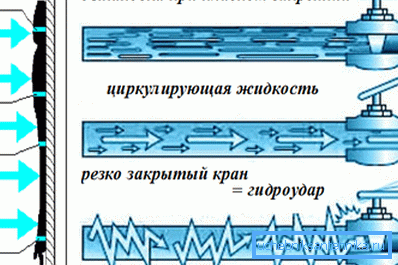

- In centralized heat and water supply systems, the likelihood of a hydraulic shock always remains. With the fast filling of the discharged pipeline or with the valve of the screw valve at the front of the shock wave occurring in the liquid medium, the pressure can reach 20-25 kgf / cm2.

- With increasing temperature, the mechanical strength of polypropylene decreases. Working pressure is indicated by manufacturers for room temperature (+20 C); at +90 С, quite achievable in the central heating system, the maximum allowable pressure will drop to 7 atmospheres.

Reinforcement

For the CWS wiring, a polymer without reinforcement is used. The temperature regime is far from critical and, more importantly, stable, which implies low requirements for mechanical strength and coefficient of linear expansion during heating. From here - the minimum price of the corresponding pipes.

However, when the temperature of the transported medium is high, two technical problems arise:

- Approaching the boiling point of water leads to a critical drop in the strength of the plastic.

- Temperature fluctuations in the range from room temperature to 80-95 ° C lead to continuous changes in the linear dimensions of the pipe.

The problem is partly solved by the introduction of a reinforcing layer into the polymer.

On sale you can find material with two types of reinforcement:

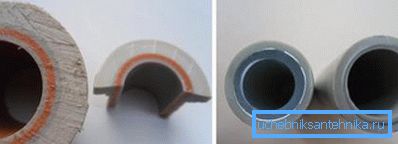

- Aluminum foil. It is glued between the layers of the polymer (approximately in the middle of the wall or closer to its outer surface).

- Fiber (chopped fiberglass). A layer of fiber-mixed polymer is fused between the outer and inner layers of pure polypropylene.

Each type of reinforcement has its pros and cons.

| Reinforcement | Foil | Fiber |

| Dignity | Smaller linear expansion coefficient approaching that of steel pipe | Impossibility of pipe splitting due to poor quality of adhesive or electrochemical corrosion of aluminum |

| Disadvantage | The probability of delamination in the destruction of the foil or due to poor-quality adhesive layer | Greater linear expansion |

Pipeline installation

So, how to cook polypropylene pipes?

Tool

Let's start with the preparation of the tool.

We will need:

- Low-temperature soldering iron with a set of nozzles of the appropriate diameter.

Tip: on sale you can find soldering irons with temperature control. The regulator should allow to set the optimal for our purposes 240 - 260 degrees.

- Scissors for cutting polypropylene. They often come bundled with a soldering iron.

- Knife for removal of a facet from a pipe.

- When working with aluminum-reinforced pipes - the so-called stripping (shaver) for the external arrangement of the reinforcing layer and the end facer - for the internal (in the middle of the wall). Tools are available in the form of nozzles for the drill, and by hand cleaning.

Cutting, Stripping

The cutting instruction does not contain any secrets: the pipe is laid out taking into account its immersion in the fittings and is cut off with a scissors-cutter. Then a chamfer is removed from its outer side.

The stripping of aluminum foil is carried out with several turns of the shaver / facer. The goal is to prevent aluminum from contacting water. Under certain circumstances (in particular, if copper is present in the circuit, with which aluminum forms a galvanic couple), the foil may corrode, which will lead to the already mentioned pipe separation with a catastrophic decrease in the strength of the joint.

Compound

How to cook polypropylene pipes with your own hands using a soldering iron?

- A nozzle of the appropriate diameter is mounted on the heating element..

- The tool warms up to the standard temperature..

- The inner surface of the socket fitting and the outer surface of the pipe segment are combined with the nozzle at the same time..

- After the polymer is melted, the parts are combined in a smooth forward motion and held in a static position until the melt sets.. Turns are unacceptable: they will create a wave on the melted surfaces. which will drastically weaken the connection.

How long does it take to heat and set? The answer depends on the diameter of the pipe:

| Outer diameter (millimeters) | Duration of heating (seconds) | Duration of fixing parts (seconds) |

| 75 | thirty | ten |

| 63 | 24 | eight |

| 50 | 18 | 6 |

| 40 | 12 | 6 |

| 32 | eight | 6 |

| 25 | 7 | four |

| 20 | 7 | four |

| sixteen | five | four |

The tool for polymer welding is inexpensive; However, the most economical readers may still have a predictable question: how to weld polypropylene pipes without a soldering iron?

With a small diameter of the pipeline it can be replaced by a gas burner assembled on a knee from a can and nozzle to it. In a flame of a torch both welded surfaces simultaneously melt; further operations are no different from the above case. The disadvantage of the method is that without long workouts it is difficult to obtain a uniform melting of the parts.

General rules

At installation by polypropylene of systems of GVS and heating it is necessary to consider the main feature of plastic - considerable linear expansion when heating.

- Clamps on long sections should not prevent the pipeline from moving along its own axis.

- When laying in the grooves between the pipe and the end of the grooves, a free space is left blank with plaster (0.5 - 1 cm).

- Straight-line sections with a length of over 3 meters are supplied with annular or U-shaped compensators.

Conclusion

We hope that our simple recommendations will help the reader to avoid the most obvious mistakes. As always, the attached video in this article will complement it with a visual acquaintance with the methodology of work. Successes!