Inset into the water supply under pressure

It may well happen that you urgently need to insert a frame into the existing water supply system, for example, in order to attach an additional device (washing machine or dishwasher) to the water supply system, or if a new private house was built, water supply is required to it, or the old supply is clogged and needs to be replaced. . But it is not always possible to turn off the water. There is only one way out - a tie-in to the water supply under pressure with your own hands.

The essence of the process

In order to intervene in the water supply system, which is filled with water under pressure, brought minimal damage, it is necessary to figure out what to do and how. Let's start with the pipe material. Modern water pipes are mounted from metal, plastic and metal pipes. Less common cast iron pipes.

In order to crash into such a pipeline, it is necessary to make a hole in it. It goes without saying that a jet of water will immediately "burst out" from it. Therefore, it is necessary to provide - how to quickly and reliably close this hole, but so that it was possible to subsequently attach to it the continuation of the branch. In other words, after the hole has been made, the stop valve is cut with the possibility of attaching an additional pipe to it. Basically, the insert in the water supply under pressure is produced using special clamps. The construction of these devices depends on the pipe material.

Tie-in technology

Consider from a practical point of view, how to make a hole in the pipe with water. There are two general rules when tapping into a pipeline:

- The pipe that is punched must be smaller in diameter than the pipe in which the hole is made.

- The diameter of the drill should correspond to the internal diameter of the pipe being cut in, which, in turn, should be smaller than the main pipe.

Tip! When working on the sidebar must comply with all safety measures.

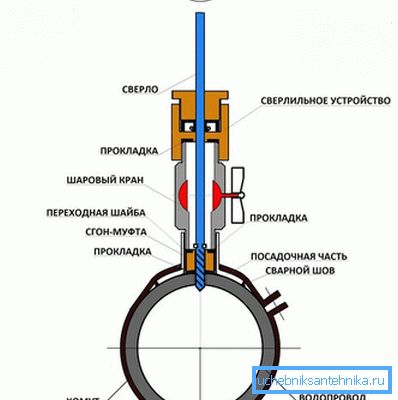

If you need to bump into a metal water pipe, you will have to use a saddle strap for tapping with drilling. Saddle collar is called because its lower part is a semicircle that looks like a saddle. There are several varieties of these clamps. Before installing this device on the pipe, it must be thoroughly cleaned from dirt and rust (if any). In addition to the “saddle”, the clamp has a shut-off valve with a hole for drilling and a drill in the upper part. Both parts on the pipe are bolted to each other. The clamp fits snugly to the surface of the pipe using sealing rubber. After fixing it with a drill, make a hole until water appears. Then the drill is unscrewed and the plug is closed with a special screw to prevent water from flowing out of the pipe. In the future, such a clamp can be used as a stop valve. You can also use the clamp already with the valve screwed into it.

After the hole is ready, the drill bit is pulled out and the valve is closed. Now you can perform other works on the installation of water supply. Another simple metal clamp can attach a special machine, the main elements of which are a handle with a ratchet, a locking bolt, a shaft with a drill at the end, a flushing tap. All this is enclosed in a metal case and is attached to the clamp with the help of sealing gum. The directing coupling allows to drill in the set direction. With it, drilled metal and cast iron pipes.

For drilling cast iron pipe under pressure using bimetallic crowns and clamps of special design. The nuance of working with cast iron is that:

- It is necessary to work with a slight pressure. Cast iron is a brittle metal, it does not work well in compression and tension;

- pre-clean the surface of the pipe from a special layer deposited on the surface to prevent corrosion;

- do not allow overheating of the crown;

- work should be at low speeds.

If you want to crash into a plastic pipe, it is better to use an electrically-welded saddle-saddle. It is made of special plastic, equipped with a heating coil and drilling mechanism. On the saddle body there is a bar code that allows you to accurately enter the necessary parameters: welding and cooling time, etc. The clamp is bolted to a pre-cleaned pipe. With the help of a special welding apparatus, the helix is heated and the outlet is welded (clamps are provided on the clamp for connecting the welding). Then, an hour after cooling, a hole is made through the special milling cutter and the stop valve is screwed on.

Metal-plastic perform mainly water distribution around the house or apartment. Consequently, the diameter of the pipes is small. If there is no inlet valve and it is not possible to turn off the water using special services (ZhEK, water channel), then it will be necessary to bump under pressure to supply water to an additional point. The use of clamps in this case is not advisable due to the small diameter of the pipe. How to make a sidebar? Very simple. It is necessary to prepare a water tank, floor cloth, tool, valve and special fasteners. The pipe is cut. The end from which water flows, is lowered into a container with water. He puts on the nut, clamp. Then the valve is inserted into it in the open position, which is clamped with a nut. Then, having closed the crane, it is possible to continue installation.

Special features

All the proposed methods of tapping into the water supply system require a certain qualification of experience and the availability of special tools. After all, it is necessary to act quickly to prevent a large leak of water. If the tie-in occurs in the main pipeline, which is located underground, then the pressure of the water is quite large and it is not very pleasant to take such a “shower” even in summer. Moreover, the work is done with a hand-held tool, for security reasons the power tool is not used. In addition, if you independently perform a tie-in to the main pipeline, then you will have to get permission from the water supplying organization - the owner of the pipeline. And this is associated with a certain paperwork, waste of time and nerves.

When it is necessary to bump into the supply pipeline in the middle of an apartment building, then slowness will lead to the flooding of the lower floors.

Of course, no one can forbid a man himself to perform such work, but for this it is necessary to have a set of certain tools. Buying them for one-time work does not make much sense: the tools are expensive, and after tapping they will simply roll in the storage room or garage until the next event. Therefore, judge for yourself how much an independent tie-in is possible in a water supply system under pressure. The decision, of course, is up to the person, but the most reasonable thing to do is to invite a specialist with experience in doing such work.

Video

This video shows a tie-in of a polyethylene pipe with a Poly16 Plus saddle with a cutter:

See how the Tonisco Jr pressure tapping device works:

A photo