Installation of ceramic chimney

High requirements for temperature stability and durability are imposed on the flue gas discharge channels. Ceramic structures have become a worthy alternative to brick chimneys. Fire retardant ceramic pipes are used for boilers with any type of fuel. The high cost of construction is combined with a long service life and resistance to aggressive environment. Installation of a ceramic chimney requires compliance with safety rules and technological standards, these conditions will allow to avoid fires and ensure high quality discharge of combustion products.

Device

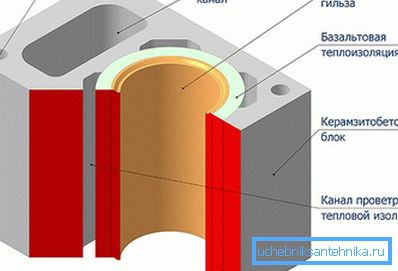

The universal chimney system is a sandwich construction consisting of an inner ceramic pipe and an outer part made of lightweight ceramic chimney bricks or concrete blocks.

Between the layers of fireproof insulation is laid, such as basalt wool. Chamotte clay, which is a raw material for the manufacture of heat-resistant ceramics, provides the ability to install a chimney for boilers with a high temperature of exhaust gases. This material repels moisture and is immune to the effects of combustion products.

The design of the smoke channel provides a sufficient degree of insulation, eliminating the appearance of condensation on the walls. The escaping gases retain heat to the hole in the pipe, only here they are cooled to the formation of moisture. A small area exposed to condensation does not have a significant effect on the ceramic chimney. The design is designed for installation both inside and outside the house.

Merits

The use of natural refractory material inside the structure, insulation and concrete blocks outside gives a number of advantages over brick and metal chimneys:

- Improvement of draft due to smooth walls of a ceramic pipe that does not have brick roughness.

- The chimney made of chamotte clay is superior to metal in corrosion resistance. Due to the sandwich construction, the channel slowly cools and condensate does not appear. Combustion products do not settle on the smooth clay walls of the pipe; therefore, no aggressive solutions that destroy the material are formed.

- The absence of soot ensures the safety of use - the smoke channel does not decrease in diameter and does not provoke ignition of deposits.

- Universality - the ceramic chimney is suitable for gas boilers, solid and liquid fuel units, fireplaces. Designs are made for use with a high degree of heating and special pipes for low-temperature boilers.

- Good thermal insulation ensures fast heating and low heat loss, these factors increase the efficiency of the heating system.

- The sandwich pipe complies with the fire safety requirement, its external frame made of concrete blocks does not heat up and carries threats to wooden floors when passing through residential floors and roofing.

- Long service life, up to 30 years warranty.

- A simple installation of a modular chimney system is available to do it yourself.

When choosing a ceramic pipe, its drawbacks are taken into account: the installation should be carried out vertically without turns, the cost of such a chimney is higher than that of a brick or metal one, the total weight of the structure creates an additional load on the foundation.

Selection rules

The ceramic chimney pipe is made of separate blocks that fit tightly together, so there is no smoke leakage. Its height is calculated in advance, according to current regulations. The excessive length of the chimney does not improve the draft, but will only create complex aerodynamic turbulences that do not contribute to the efficient operation of the gas exhaust system. Pipe recruited, guided by the rules:

- height above the flat roof 50 cm;

- the pipe, located 1.5 m from the ridge, should rise 50 cm above it;

- at a distance of 3 m, the edge of the chimney cannot be below the ridge line;

- being more than 3 m from the ridge, the pipe must reach an axis at 10 degrees from the line of its horizon;

- the diameter of the inner ceramic channel can not be less than that of the smoke exhaust pipe;

- the height of the pipe from the grate line to the outer edge is not less than 5 m.

A ceramic chimney can be used to divert gases from several appliances, but in any configuration the bottom module serves to collect condensate. Elements of the chimney are selected, focusing on the type of heating device: a fireplace, boiler or stove. The size of the pipe diameter is influenced by the type of fuel and the power of the boiler. To calculate the required length of the ceramic chimney you need the height of the ceiling and roof.

Chimney installation

Manufacturers produce a design completely ready for assembly, it includes:

- ceramic blocks, including tees for cleaning and connecting to the heater;

- condensate tank;

- frame made of blocks with holes for reinforcement;

- mineral insulation.

The top of the chimney is protected from precipitation by a special cone. In the lower part of the structure, a grille for air flow is installed. Selecting the installation sequence of the modules and the size of the pipe, take into account that the joints of individual sections should not fall on the overlap aisles.

The significant weight of the chimney requires laying a separate foundation. Its dimensions exceed the diameter of the chimney by 10 cm in each direction. The concrete base must be flat, its horizontal position is checked by level. To ensure a flat plane, you can lay ceramic granite tiles. The base of the pipe, especially those exceeding 7–8 m, should be set strictly on the level. Next, waterproofing is performed from the roll material, folded in two layers. The first concrete block is laid on the foundation; cement mortar is used under it.

A special sealant is used to connect sections of the ceramic pipe. It is made independently of the dry mix, included in the kit, and water, the ratio of 7: 1 is maintained. Mixing takes place in a warm room at +20 degrees, it is necessary to use the composition for 1-1.5 hours until it hardened.

Tip! The frozen solution cannot be re-diluted with water.

A tank for condensate draining is installed in the first block; a pipe section with a cleaning hole is attached to it with a sealant. This module is wrapped with basalt wool. Each subsequent module is put into the previous one and sealed with a manufactured solution. Excess composition protruding to the surface of the pipe is wiped with a damp sponge. Outside of a ceramic pipe, a frame of concrete blocks is connected, connected with a cement-sand mortar. If necessary, they are cut holes for individual sizes of tees. The straight part is made of blocks without holes.

The third module is a tee for connecting the heater. It is covered with a special front insert. After the straight section, a flap is installed.

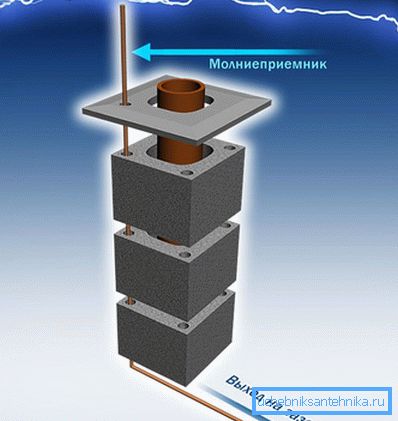

Tip! Through the concrete sections of the ceramic chimney can be brought lightning rod.

When installing blocks, it is important to observe the horizontal and vertical levels. To give the structure stability and rigidity it is reinforced with iron bars. Holes in the corners of the blocks are made up under the metal reinforcement; segments of 1.5 m are pushed into them and filled with cement mortar.

After the chimney is installed, the tee for auditing is closed by a door, and a ventilation grill is installed in the lower unit. The air entering through it will move inside the channel and reduce the temperature. Ceramic chimney is installed without a concrete frame, but in this case, the pipe is attached with clamps every meter. In an unheated attic, it is insulated with a layer of basalt wool.

Passages through the floor and attic are protected by a box and insulated with basalt wool. Particular attention is paid to the safety of installing a ceramic chimney in a wooden house. Its location is provided at 25 cm from the wooden wall.

The final part of the chimney, located on the roof, ends with the installation of a cover plate of concrete and a protective cone of metal. Exterior finish of the chimney is made of tile or other material to the taste of home owners.

We also invite you to read the articles:

- How to clean the chimney from soot.

- Installation of chimney sandwich pipes.

Video

This video shows how to install a TONA ceramic chimney: