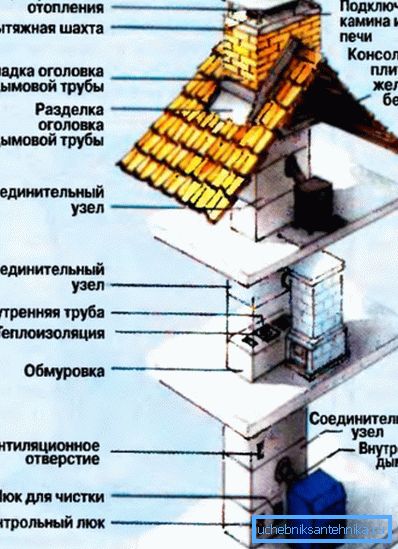

Installation of chimneys inside and outside buildings:

Chimney - one of the most dangerous elements of the exhaust system from the furnace or fireplace. When installing it, be sure to follow the rules and requirements of fire and sanitary safety. In the article we will consider the correct installation of chimneys and everything related to this process.

Alas, fires are far from uncommon when using stoves and fireplaces, and it is not always possible to prevent them in the bud. Often a sense of danger brings us, and then, an extra armful of firewood can cause a catastrophe, since burning will occur not only in the furnace, but throughout the length of the chimney.

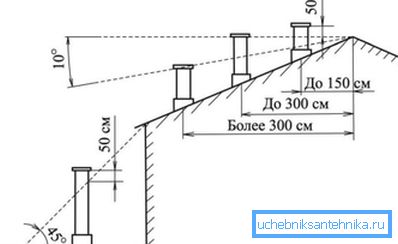

Tip: according to fire safety regulations, the distance between the chimney and structures made of combustible materials should be at least 500 mm. A timely examination of the chimneys installed in the house will avoid catastrophic consequences.

Types of chimneys

They are made from different materials, including:

- bricks;

- ceramics;

- black and stainless steel.

Also, they are internal and external:

| Interior |

|

| Outer |

|

Cutting

So called non-combustible space, including the air gap located between the building structure and the smoke in the furnace. In a brick kiln, the cutting is done from the same brick that went into making the kiln and pipe.

For better understanding, let's use an example:

- When the stove is built into the wooden inner wall of the house so that it can heat two rooms at the same time, an opening from the floor to the ceiling is made in the wall that is wider than its width.

- The gaps between it and the opening are filled with brickwork, which is called cutting. If they were not filled in, they would be called a digression.

Tip: reconstruction of the chimney will increase its capacity.

Second example:

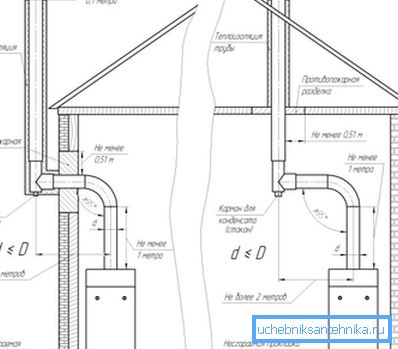

- The cross section of the passage in the ceiling for the installation of the pipe through it should be greater than the cross section of the latter, while thickening the walls of the brick pipe.

- In this case, the thickening is also called cutting. Experts say that this is not hot part of the furnace, adjacent to the enclosing structures.

Cutting can be made from any non-combustible material, in particular:

- bricks;

- asbestos cement sheets;

- foam concrete or concrete;

- metal.

Tip: you can reduce the width of the cut-up to 380 mm by protecting the combustible adjacent structures with a metal sheet over asbestos board.

Shielding

Experts recommend installing a metal screen with an insulating layer, which is made of mineral basalt wool 10-20 mm wide. In this case, the level of thermal insulation will correspond to a layer of brick of 125 mm. This solution allows to reduce the distance from the chimney to the combustible structures in the roof to 130 mm. But, do not do it without extreme necessity.

Most often, the cuts are covered with metal or asbestos-cement flat sheets, the second option is worse. If their thickness is insufficient, use steel structures, excluding sagging, or gaskets of asbestos cement sheets, which are 8-20 mm thick.

It should be borne in mind that the pipe should be able to elongate and expand due to heating, freely moving in the gaps of the sheets or bending them without fail. Note that thermal expansion can increase the length of a two-meter chimney up to 5 mm. Therefore, when installing the screen, it must be borne in mind.

Tip: it is not necessary to firmly attach one of the ends to the pipe, because when heated, the shielding shell will start to lengthen slightly.

Sealing the joint of the chimney with the roof

To do this, use heat-resistant non-flammable sealants, for example, cartridge type. The easiest way to achieve sealing between these elements is to wind the pipe with an asbestos cord, soaked previously in a clay-sand solution, and then smear the place with a mixture of sand and cement.

Tip: use to protect against leaks that may occur due to the periodic thermal expansion of the chimney, metal sheets, installing them around its perimeter.

It should be remembered that due to leakage, the junction of cold roofing material and hot pipe becomes an unreliable element. In addition, the evaporation of moisture when the furnace is kindled in these places may resemble hot spots. Therefore, experts recommend installing insulated shielded pipes, despite the fact that their price may be high.

Chimney installation

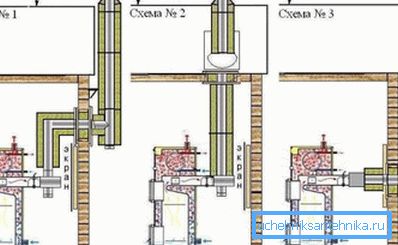

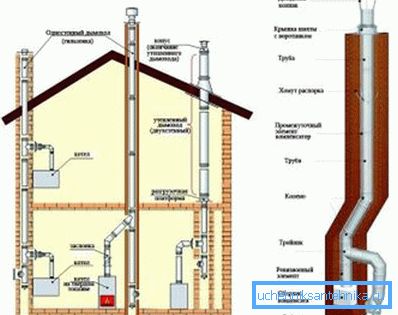

In this section, we consider two options for installing a chimney:

- industrial design;

- homemade.

In the first case, we will use the construction of a screened chimney, the manufacturer of which are Finnish companies specializing in wood-burning stoves. It is a stainless pipe with insulation - heat-resistant basalt wool, the outer casing (screen) of galvanized steel.

Installation in the screen is carried out using shaped end caps. The construction is mounted directly on a non-thermally insulated chimney so that the part in the casing starts at a distance of 400-1000 mm from the ceiling. This allows you to withstand the necessary fire regulations for chimneys.

However, in this case we should not forget that the screen can also warm up to a temperature in excess of 80? C, which also becomes dangerous. To prevent fire, it is necessary to provide for a cut-out of a width of 380 mm from the chimney, despite the additional protective elements.

Note! These requirements correspond to the domestic standards of installation, which cannot be interpreted differently. The rules of operation of flue and ventilation pipes must be strictly observed.

It is necessary to take into account that the Finnish recommendations, which allow the installation of a chimney straight butt with a casing, are considered illegal here. The dignity of the Finnish construction - the chimney rests on the stove, not on the roof, ensuring greater safety. You can make it yourself, having certain skills of this work.

The instruction is quite simple:

- Weld the frame of the corners for shielding pipe.

- Sheathe it with galvanized steel sheets.

- You can hang the casing on a cutting sheet and install additional protective screens.

Homemade chimney construction usually passes through the roof, combined with the ceiling. This allows you to save on building materials and increases fire safety. A similar design is often installed during the passage through the attic.

Conclusion

Smoke is usually called hermetic vertical pipe, the main task of which is the removal of combustion products. And since it is difficult to constantly monitor the operation of the chimney, during installation you should not deviate from the rules of fire safety.

The main role in this case is assigned to cutting - the gap between the chimney and combustible structures. The video in this article will help you find additional information on this topic.