Installation of heating from polypropylene pipes

Polypropylene pipes - one of the most popular polymeric materials. The demand for them is growing along with the confidence of the population in the performance of this product.

Before you install the heating of polypropylene pipes, you should be familiar with the basic functional properties and quality characteristics of polypropylene.

The advantage of polypropylene

Polypropylene has high heat resistance. Its softening temperature is higher than 150? С, the material begins to melt only when heated to 170? С. This quality allows to use widely pipes from polypropylene when mounting systems of heating where the temperature of the pumped water exceeds 100? С.

Tip! The advantages of communications made from this building material include strength and resistance to mechanical loads, high moisture resistance (0.5%).

The disadvantage of products from polymeric materials is their instability to the effects of ultraviolet rays at high temperatures. But the technology of pipe production provides for a similar property of the material. Various stabilizers are added to polymers from which further designs will be made, various stabilizers are added to increase the durability of products. Fiberglass and aluminum, which reinforce the pipes, protect them from overheating in the sun, increase resistance to aggressive media.

Additional advantages of polypropylene pipes that you should be aware of:

- durability (from 25 to 50 years);

- wear resistance of internal walls (do not give in to corrosion);

- excellent sound insulation properties;

- the formation of a monolithic structure when connecting;

- welding machine or soldering iron are the main tool for installation;

- metal parts are reliably protected from oxidation and corrosion by the walls of pipes that do not allow oxygen to pass through;

- unlike steel pipes, they are not plugged with salts accumulated on the inner wall;

- due to the improved circulation of the energy carrier, such pipes possess high heat emission;

- democratic cost of goods with high performance;

- durability and reliability of polypropylene structures;

- polypropylene inertness speaks of its harmlessness and environmental friendliness.

Choosing pipes

Solid polypropylene pipes differ in three pressure ranges: PN10, PN16, PN20, PN25. That is, they differ in the parameter of the nominal pressure of liquids and gases moving through them.

Pipes PN20, PN25, able to effectively cope with their functions at a nominal pressure of 20 or 25 Bar, are perfect for installing a central heating system or a water supply system that supplies hot water.

Underfloor heating and conventional hot water can withstand PN16 pipes, and PN10 are suitable for plumbing with cold water.

All types of structures are produced in accordance with the established standard. Wall thickness depends on the expected operational temperature values and fluid pressure in communications.

Tip! The diameter of the pipes used for installation of the heating system depends on its length: a pipeline with a length of up to 30 meters is mounted from pipes with a diameter of 25 mm, and more than 30 meters - 32 mm. When the length of the water supply is less than 10 meters, then it will be enough products D = 20 mm. The diameter of the riser should be at least 32 mm.

When choosing polypropylene pipes, the appearance of products is of particular importance:

- even round shape indicates excellent quality;

- the homogeneity of the material from which the product is made indicates its reliability and durability;

- pipes must be labeled.

Using the proposed tips, just choose a quality construction product.

Mounting algorithm

Before starting work, the first thing to do is to make a detailed project of the pipeline. It is important to take into account the space they occupy and do without unnecessary turns and details in the design. It is necessary to take into account the factor that the layout of the pipes of the heating system and plumbing will have several differences.

Scheme of laying of the pipeline from polypropylene pipes:

Having carefully considered the nuances, selecting the material and preparing the necessary tools, you can begin to install communications. It is important to provide a slope angle made towards the lowest point of the system where the drain valves or valves are installed. stable base under the tee (or above it), preventing the structure from sinking.

Pipe redirection (rotation), performance of a loop-like or other type of compensator are the methods used to compensate for the structure located between the stable bases.

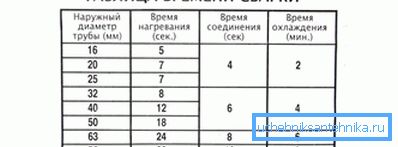

The welding of the water-pressure system is performed by special equipment and devices that control the parameters of the weld. A special soldering iron creates a compound by diffusion welding. Works are performed strictly according to the instructions attached to the equipment.

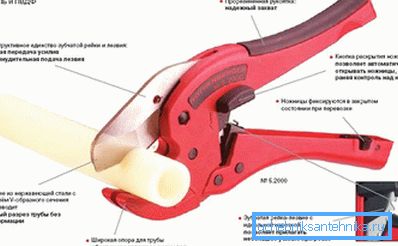

For cutting propylene pipes, special scissors or a pipe cutter are used, which should be well sharpened.

Installation of plumbing and heating systems, performed independently, implies the presence of jumpers with brass inserts having external and internal threads. The high-quality installation of the pipeline represents a communication system, the installation of which is carried out strictly according to the project.

Interconnected parts of the water supply chain must be fixed so that in case of an emergency it is possible to close them and to repair them without interruption of the entire system.

Be sure to take measures to avoid sagging pipes. Here special holders come to the rescue (it is better if they are made of cast iron or stainless steel), providing a stable and reliable fastening.

Water fittings must withstand the pressure in the system. Only in this case it is subject to installation. The presence of open valves mounted in the pipe is required. It is possible to replace the water intake structure stopper.

Necessary conditions for the installation of polypropylene communications

The stable pressure in the pipeline and the temperature guarantee an effective, safe and durable operation of the water and heating communications.

Mounting of polypropylene products is the best option in systems where there are no unexpected changes in temperature parameters and nominal pressure. A supplement in the form of a heating boiler that limits the temperature of water heating is the best option for a polypropylene pipe.

Tip! Polypropylene products should not be used when installing central heating systems in which temperature changes occur abruptly and the pressure is not constant.