Installation of heating pipes yourself

The country house, which is supposed to be year-round, needs a properly planned and equipped heating system. In recent years, many are decided on an independent installation of the heating system.

- First, the cost of installing the heating system with the help of professionals will cost a decent amount, not counting the cost of building materials;

- Secondly, installation of heating from polypropylene pipes is one of the simplest tasks.

The choice of material for the arrangement of heating systems

When planning a heating system, it is important to decide which pipes it will be made of. The most popular are:

- metal pipes,

- steel tubes,

- polypropylene pipes.

Metal-plastic, as a material, is characterized by high flexibility, frost resistance and resistance to various internal deformations or the occurrence of deposits. Their term of service is at least 50 years. However, metal-plastic pipes are very sensitive to the effects of ultraviolet radiation, as well as to mechanical damage from the outside, so when assembling the heating system from metal-plastic pipes, it is necessary to consider how to protect them — whether to lay them in special boxes or wall them in the wall. In addition, the arrangement of the heating system of metal-plastic is difficult to organize without having some professional skills.

Steel pipes are characterized by high heat dissipation, but their installation is the most difficult: it can only be carried out if there is a welding machine. Steel pipes are heavy enough, and their connection is a laborious process. Steel pipes are subject to corrosion and have a relatively short service life.

Polypropylene pipes have both a greater wall thickness and a larger diameter, which significantly affects their carrying capacity. Resistant to mechanical and chemical damage, pipes made of polypropylene, however, do not have sufficient flexibility, so that to obtain rounding it is necessary to apply certain technologies to bend polypropylene products. The service life of such pipes is at least 50 years.

Stages of installation of the heating system

- Planning and acquisition of materials. The competent heating system, which is installed independently, intermittently or not, depends on proper preparation of the pipe layout and the number of radiators.

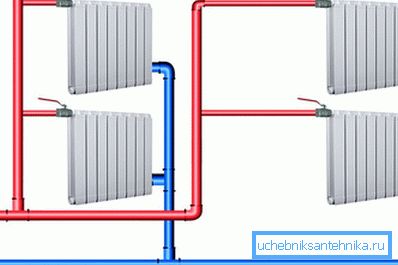

- At the time of planning, not only the number of radiators is determined depending on the number of rooms, but also the location of the pipes, their inclination, the diameter of the pipeline and the option of connecting the pipes to the radiator.

- The wiring diagram is drawn up after a thorough inspection of the premises, at the same time the decision on the use of metal-plastic or polypropylene pipes is made.

- Initially, you should determine the location of the radiator, as well as the layout of the pipes for its connection. Most often, radiators are installed in the rooms under the window. To mount the radiator, you need to carefully fasten powerful hooks on the supporting wall, on which the battery will be hung.

- If the installation of heating pipes with their own hands is carried out in the apartment, then the wiring pipes in the apartment is held from the riser. If the heating system is mounted in a private house, at the planning stage it is necessary to select and install a boiler for heating in the basement or basement.

- In preparation for distributing the heating system, it is also necessary to choose the method of laying pipes. The most convenient, though not aesthetic, is the open laying of pipes. It allows you to quickly notice any defect in the system and quickly eliminate it. In addition, this method of installation is characterized by increased heat dissipation. For installation in this case is not required to purchase any additional building materials.

- After the planning stage, it is time to take action: first the boiler is installed, then the radiators are installed in the room, then, in accordance with the wiring plan, pipes for the batteries are installed from the boiler in a private house or in the riser, if installed.

- Depending on the material from which the pipes for the heating system are made, they are mounted in the following ways.

Metal pipes

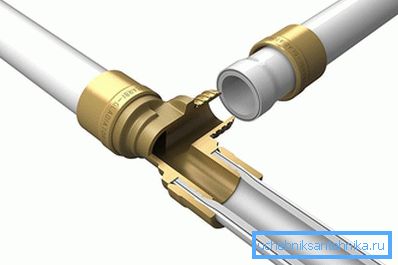

Such pipes are connected using compression fittings. This requires adjustable wrenches of different diameters, scissors for cutting metal-plastic pipes, a reamer designed to give the correct shape to a metal-plastic pipe, sandpaper.

At the site of the future cut, the pipe must be straightened at a distance of 10 cm. The cut is made at an angle of 90 degrees. The ends of the cuts are ground, and with the help of a reamer they are given the correct round shape. A fitting is put on the prepared pipe, and the connecting nut is tightened on it.

Steel tubes

Installation of steel pipes is difficult for those who are going to deal with them independently and for the first time. First, heavy construction material itself; secondly, pipe welding is necessary, which requires skills in working with the welding machine, in some cases a threaded connection is used, but then the thread must be able to be cut.

Polypropylene pipes

They are remarkable for not only the building material, but also the installation as a whole. Welding them also requires special equipment, but is much less problematic than welding steel pipes.

Tip! Instead of a welding machine, it is sufficient to use a soldering iron, with which the pipe section is heated to the melting point, when a solid connection of polypropylene pipe segments occurs.

For arranging bends or turns of the heating system, you can use various couplings, tees or fittings, allowing you to implement a variety of options for the location of the heating system in the room. If the required connecting element is not available, polypropylene pipes can be bent at the required angle independently.

The final stage of installation of the heating system is to check the system for possible errors or defects, leaks.

Video

This video tells about the heating system of a private house.