Installation of pnd pipes

Arrangement of various water supply, sewage or drainage systems has become much easier and more accessible with the advent of pipes made of low-pressure polyethylene.

Relatively recently appeared building material - low-pressure polyethylene or HDPE - has undeniable advantages over the usual materials for the organization of pipelines:

- HDPE is a durable and lightweight material, practically free from various mechanical or chemical influences, which makes it possible to organize an external pipeline from this material.

- Low pressure polyethylene is very elastic. When you try to break or emergency it stretches, while maintaining its integrity.

- Installation of HDPE pipes is easy to perform.

However, the use of low pressure polyethylene pipes has some limitations:

Tip! Work of the pipeline from PND is possible at temperatures from 0 to 40 degrees Celsius. It means that the laying of the pipeline in the ground requires high-quality insulation, and for the supply of hot water or the organization of the heating system, the PND pipes are not suitable.

Mounting methods

Depending on the purpose of the pipeline, their installation can be carried out using:

- fittings;

- parts having heaters;

- butt cooking.

With fittings

This type of connection can be characterized as detachable. It is required in areas of the pipeline where local or partial repair may be necessary, then with the help of fittings, you can dismantle a part of the system and replace parts with new ones.

HDPE pipes with a diameter of no more than 11 cm are suitable for detachable connections. They are quite suitable for organizing a HDPE pipeline for supplying cold water or draining sewage in a private house or apartment.

For the installation of the system, both low-pressure polyethylene pipes and special connecting elements are required: flanges or fittings. Experts recommend the use of brass connecting elements - they are more durable and easy not only installation, but also dismantling.

Organization of work when using fittings to connect pipes from HDPE:

- Using a pipe cutter, it is necessary to cut pipes from low-pressure polyethylene to the required length strictly at an angle of 90 degrees.

- The ends of the pipes must be cleaned and marked up - according to the depth of the fitting, for how long it will be necessary to insert a length of pipe into the connecting element.

- Installing HDPE pipes with your own hands will be easier if their ends and holes of the fitting are slightly smeared with soap.

- Immediately before starting work, it is required to loosen the fittings, if possible. So it will be easier to insert the ends of the pipes into the connecting element up to the stop or the applied marking.

- After proper placement of the pipes in the fitting, it is necessary to tighten the fittings to their original condition.

With the help of heating elements

To create a strong section of the pipeline, you can use the so-called electrofusion - in fact, the same connecting elements, only with heating elements. Heating fittings are built into such fittings, to which it is necessary to apply current for a short time to heat them. As a result of heating, pipes and fittings made of HDPE melt to such a state that they are joined, but not deformed. Installation of polyethylene pipes in this way allows you to get a solid pipeline section in cramped conditions in a short time. A connection of this type can be created on pipes with a diameter of not more than 16 cm.

The procedure for installation with the help of electrofusion:

- First, using a pipe cutter, PND pipe sections of the required length are prepared. Their edges, as well as the connecting part, are cleaned, and with the help of a pencil or a marker, a marking is applied to their ends to insert the pipe sections into the connecting part until it stops.

- After placing the pipes in the fitting, it is necessary to prepare the welding machine for operation. Pipes with a connecting element are placed in the positioner. The pins on the fitting are connected to the device. The duration of welding and other parameters are indicated on the fitting.

- Only after complete cooling can the pipeline be removed from the positioner.

Butt

This type of connection is suitable for large diameter PND pipes. Butt welding requires a special electric heater.

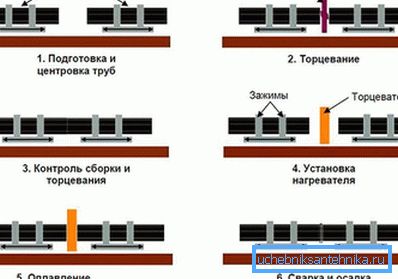

Works in this case are carried out as follows:

- The ends of the pipes are prepared - cut off at an angle of 90 degrees, trimmed until the ends are completely smooth - fixed so that they stand as close as possible to each other. A heating element is located around the place of the future connection.

- The edges of the pipes are heated to the melting temperature, after which the heating element must be removed and wait for the joint to cool completely.

Video

We invite you to watch a video on the topic of our article.