Insulated pipes: purpose, features, scope

Domestic pipelines are designed to transport water, which tends to freeze when the temperature drops below zero and expand in volume, breaking even steel and cast iron. Also, some channels carry overheated substances, such smoke or steam, which is dangerous due to the occurrence of fires or burns. We will tell you how to install insulated pipes for sewage and other engineering systems.

Weatherization measures

Purpose, materials, methods

The purpose of measures for weatherization is fairly obvious, however, quite reasonable questions may arise here.

If the highway is laid below the level of soil freezing, then why this conversation?

- Firstly, it is far from always and far from the whole length of a highway there is an opportunity to clearly fulfill the requirements for the depth of laying the system;

- Secondly, miscalculations and errors occur in the design, and in one place the system will freeze, which will lead to its complete collapse and accident;

- Third, rare peak colds occur when the depth of freezing falls on those few centimeters that were not taken into account in the design and implementation of works;

- Fourthly, sometimes SNiP or even GOST require it;

- Finally, it gives a lot of advantages, although it entails some costs.

Let's talk about the merits.

There are not so many of them, but they are significant and worthy of your attention:

- When supplying hot water for domestic needs and heating, the effect of energy saving is such that there is not even talk about the lack of thermal insulation in the circle of educated people and even the townsfolk;

- Insulations are generally waterproof, making them useful in terms of anti-corrosion and protective considerations.. They also protect the pipe from the effects of other undesirable factors - plants, pests, etc .;

- When transporting smoke from a fireplace or a bath stove, in factories and workshops often the temperature of the working environment simply does not allow to leave the pipe uncovered. Fire safety engineering instructions require isolating the surfaces of such pipes with heat-insulating materials in accordance with the project regulations based on calculations or using GOST standards;

- Consider the opposite situation: often the pipes transport cooled liquid or substance, even plain tap water. The lack of insulation, especially in summer, inevitably leads to the accumulation of condensate, rust, dampness of the walls and other unpleasant consequences.

Note! Warming the chimney with their own hands in certain nodes of the structures has been done for a long time as a necessary fire safety measure.

As insulating materials use several main classes of substances. These can be glass wool or basalt cotton wool rolls, shells, corrugations or cylinders made of rigid polymers, foam materials and electrical heating elements.

Note! Each of these types has its own characteristics, advantages and disadvantages, the description of which is worthy of a separate article.

As a rule, for warming highways of hot water and other industrial facilities use glass wool rolls, and in private construction they prefer polymer coffers and shells for pipe insulation for ease of installation and reliability.

Note! Foamy materials and electric heaters are used only in special cases because of the high cost, or when other methods are ineffective.

Sewage

If we treat water supply systems seriously and try to fulfill the requirements for their installation correctly, then the sewage system often remains in a state of “and it will do so”. This approach is becoming the main cause of winter accidents of diversion routes and drainage systems.

The fact is that dirty water, especially containing a lot of salts, detergents, sewage and mining, freezes more slowly and at lower temperatures, but still freezes. Therefore, the rules of SNiP require mandatory measures to prevent such excesses.

Most often it is enough to bury the trunk below the level of soil freezing, which is observed in most cases. However, we have already listed the problems that may hinder the fulfillment of this simple condition, in addition, the sewer pipe can rise to enter the structure and change the level of the gasket.

Note! In places where sewers exit from the ground, in places where pipes pass through walls, in places where a level is forced to rise — isolation is necessarily carried out according to local climate conditions and technical calculations.

In the construction of urban sewage systems in our time, this issue is not discussed, pipes are insulated necessarily. This is due to the fact that the cost of repairs arising from the freezing of the environment and the break of the part, is several times higher than the cost of a single insulation.

Private owners decide for themselves: who comes in the “old-fashioned” way and bury the pipe deeper, sprinkling straw and leaves, who use modern materials.

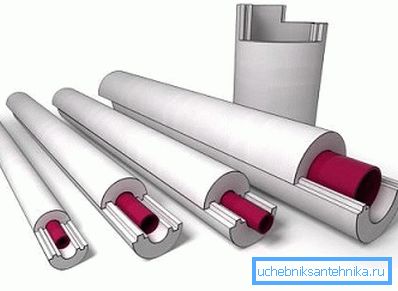

The installation of polymer and basalt cylinders, shells or coffers does not cause any problems: even a schoolboy can cope with such work. Simply put the product on the tube. Roll materials will require large skills and labor costs, but they are cheaper.

It is most convenient to use the foam shell, since this material has a very low thermal conductivity coefficient, is not afraid of moisture, is quite rigid, durable, and most importantly - inexpensive. The flammability of polystyrene under the ground can frighten only the gatekeepers of hell or inadequate people.

After laying the pipe at the desired depth (the use of thermal insulation does not eliminate the observance of the rules for the depth of the pipe), it is simply put on the assembly part. The shells move slightly so that the vertical seams do not coincide like brickwork.

In places of exit from the ground should take care of a more serious isolation: apply thick-walled models or use foam insulators, which are applied in the required quantity.

Note! Do not forget about the increased insulation in the layer of freezing ground in the place of the pipe exit to the outside.

Chimney

Thermal insulation of the chimney is no less important, since the danger of non-compliance with the rules adopted by builders and engineers leads to tragedies. This is not only unpleasant burns on the soft parts of the body of lovers to steam in the bathhouse, but also real fires with human victims. Therefore, the topic should be taken seriously, the instructions for compliance are mandatory.

Note! The main difference in the technology of the implementation of thermal insulation is the materials used. The temperature of the chimney can reach hundreds of degrees, so about any polymers and foams here we can not go.

Basalt fiber and glass wool, which are capable of experiencing high temperatures, are most commonly used. But there is another danger - the products of combustion of fuel during cooling condense and are dangerous aggressive substances from the point of view of their chemical action, the escape of which to the outside is dangerous.

To avoid this possibility, chimneys are usually insulated multiple layers. That is, the inner pipe is covered with stone wool fiber, which is again inside the pipe of larger diameter.

The most dangerous places are considered to be sections of the passage of chimney channels through walls and ceilings, where contact with other building materials is particularly pronounced. In such zones, special shields and connections are arranged that maximally protect materials from overheating.

As such shields, steel plates can be used, which are reliably insulated over the entire contact surface with a heat insulator. Also use ready-made factory sandwich chimneys, having also a two-pipe structure. Sometimes used ceramic designs.

For insulating brick pipes using a wet method of applying special plasters that prevent the spread of elevated temperatures. In this case, multi-layer plaster systems are used, and their solidity is important, and through-penetration with fasteners is not allowed.

Note! It is better to organize the internal sections of the chimney in the form of sandwich structures in order to maximally reduce the surface temperature of the pipe in order to secure the operation of the facility for people.

Conclusion

Insulation of pipes for various purposes provides a number of advantages, as evidenced by the video in this article and the positive experience of generations of masters of the furnace business.