Internal diameter of pipes: the most important parameter

Such a value as the internal diameter of the pipes allows for an accurate calculation of the throughput capacity of various engineering communications. This parameter is standardized, therefore, significantly simplifies the work of designers.

All parameter variations

The section is standardized in several varieties:

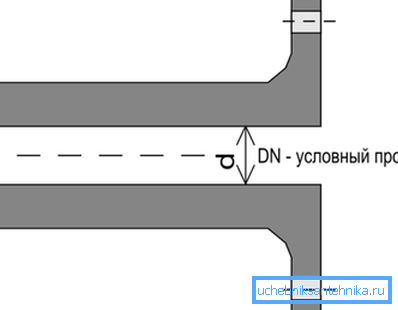

- Conditional pass is designated as Dy or Du. This parameter is calculated in millimeters or in inches - for steel (then it is rounded off).

- The nominal diameter is essentially the same as the first parameter. It is marked as Dn / Dn.

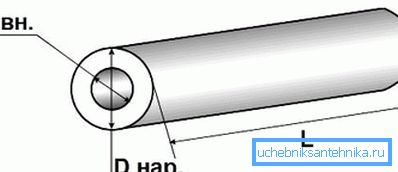

- Outer size denoted by Dh.

- The internal diameter of steel pipes (D) and their polymer counterparts is the most important value.

In addition to the above parameters, the thickness of the material wall (h) is also used in the calculations.

What is the conditional pass

Nominal passage is approximately equal to the cross-section of the pipe gap. When designing, it is calculated so that the network bandwidth is sufficient.

Note! Graduation of conditional values defined by the standard. They are calculated so that the system capacity from one pass to the next grows by 60/100%.

Their size is regulated by the GOST 28338/89 “Interfaces of pipelines and their fittings. Rows of nominal dimensions. Below is the graduation from the document.

| 2.5 | 3 | four | five | 6 | ten | 12 |

| 15 | sixteen | 20 | 25 | 32 | 40 | 50 |

| 63 | 65 | 80 | 100 | 125 | 150 | 160 |

| 175 | 200 | 250 | 300 | 350 | 400 | 450 |

| 500 | 600 | 700 | 800 | 900 | 1000 | 1200 |

| 1400 | 1600 | 1800 | 2000 | 2200 | 2400 | 2600 |

| 800 | 3000 | 3200 | 3400 | 3600 | 3800 | 4,000 |

Deciphering the concept

The term “conditional passage” was introduced to preserve the value of space for communications, which creates conditions for design calculations.

Note! The instruction means by this concept rounded down / up to the values of the standard series of the average working section. However, the actual internal diameter of the pipe is 30 mm, etc., as a rule, is not equal to the nominal analogue.

So, for materials with an external dimension of 160 and a wall thickness of 8, the actual size inside is 144, with walls of 6 - 150. But there and there the nominal size is 150.

True inner section

- The actual working space of the elements depends on the thickness of their walls.

- In most cases, water and gas pipeline materials are marked on the inside, the other types - on the outside.

- Steel products, based on the technology of its production, has the same external dimensions.

- In order to ensure the reliability of the water supply system operated at high pressure, the thickness of the walls of its elements must be increased. Proceeding from this, their working size will differ from the conditional passage.

For example, the network with an external indicator of 275 and a wall thickness of 9, has a true internal dimension of 257. And the nominal internal diameter of PVC pipe is 250 mm, which is determined by the closest value of the standard series.

Below is a table of the sizes of steel products and their correspondence to plastic water pipes to analogues. It will allow you to accurately select analogs when designing a combined system.

It can be seen from it, for example, that the inner diameter of the metal-plastic pipe 20 corresponds to a steel analog with an outer dimension of 26.

| Conditional pass | External section | ||

| Suture steel elements | Steel seamless products | Plastic analogues | |

| ten | 17 | sixteen | sixteen |

| 15 | 21.3 | 20 | 20 |

| 20 | 26.8 | 26 | 25 |

| 25 | 33.5 | 32 | 32 |

| 32 | 42.3 | 42 | 40 |

| 40 | 48 | 45 | 50 |

| 50 | 60 | 57 | 63 |

| 65 | 75.5 | 76 | 75 |

| 80 | 88.5 | 89 | 90 |

| 90 | 101.3 | 102 | 110 |

| 100 | 114 | 108 | 125 |

| 125 | 140 | 133 | 140 |

| 150 | 165 | 159 | 160 |

Defining the element workspace

By accurately determining the permeability of the parts, you can calculate the amount of matter transmitted by them over the network.

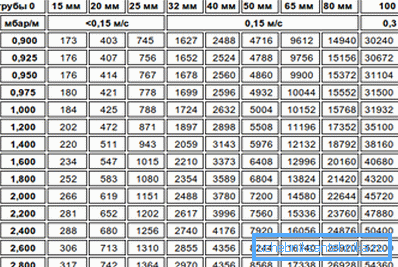

Calculation of cross-communication for cold water

How much substance she misses per unit of time will determine the internal diameter of the pipe 25 mm.

The permeability of the products depends on the following.

- Her working space. If it is too small, the hydraulic resistance of the walls of the system will increase and the flow of the working medium will weaken.

- Pressure in engineering communications.

- Communication lengths. The longer it is, the friction that weakens the flow is stronger.

- The degree of smoothness of the material. The higher it is, the faster the substance moves through the system.

- The age of the elements, i.e. the volume of deposits on their walls. The price of the system of used materials will be small, but the efficiency will decrease.

- The number of transitions in communication from one dimension to another, as well as turns.

For a household system, you can apply a simple formula. To calculate the optimal internal cross section of the elements, you need to know the cost of water, as well as the flow rate:

D = v (4-P-1000 /? • v).

Here:

- P stands for water flow;

- ?= 3.14;

- v is the speed of movement of the working environment, it is 0.7 / 1.2 m / s. in analogs with a section up to 32 mm and 1.5 / 2 m / s. in products more voiced magnitude.

Heating analogues

When it is required to do the installation of the heating system by hand, the required permeability of its elements should be calculated so that in the winter all the living rooms are heated evenly.

For the calculation of products for heating have the following formula:

D = v (? • Q) / (v • Dt).

The characters here mean:

- D is the desired value;

- number equals 3.14;

- Q is the heat flow in kW;

- v is the speed of the working environment, in m / s .;

- Dt is the temperature difference (degrees Celsius) at the input / output network.

So you can find out, for example, the internal diameter of the metal-plastic pipe 16 for the system of underfloor heating.

Conclusion

The value of the conditional space of the material is very important. The effectiveness and durability of the work of engineering communications depends on the correctness of his choice (see also the article “Pipe Inch Thread - Features and a Cutting Method).

The video in this article contains additional information on the topic.