Manual arc welding technology

Possession of arc welding techniques is considered mandatory for a home craftsman who independently masters the technique of welding (including the study of all the subtleties and features of this process). A continuous improvement of these techniques will allow him to perform a variety of operations related to the improvement of a country house.

The technology of welding pipes by manual arc welding (used, among other things, when working with pipe products) encompasses a number of subtleties that require special consideration. When mastering them, one should always remember that during welding work, great importance is attached to compliance with the requirements of GOST, which regulate the type of electrodes used, and also distinguish the type of welds that are formed.

Electrode selection

First of all, the pipe welding technique involves the use of special electrodes, which are a metal rod with a special type of coating. The functional purpose of such a coating is to form, during welding, a protective film of a given structure (the so-called slag) that prevents nitrogen and oxygen from the air from entering the seam.

Different types of electrodes are designed to perform a certain range of tasks and, according to the type of protective material, are divided into the following classes:

- with cellulose coating used for welding large diameter pipes;

- electrodes with rutile film used in the formation of fillet welds, as well as in the preparation of the so-called tacks;

- with a combined (rutile-cellulose coating) used in the preparation of complex welded joints.

The choice of this or that type of protective coating is strictly regulated and depends on many related factors (including the mode of operation of welding equipment). We also note that the use of electrodes that do not correspond to the nature of the welding work being carried out, significantly affects the quality of the welds produced.

Equipment and operating modes

For the organization of welding work in domestic conditions (including when laying pipelines), as a rule, either special transformer rectifiers are used, or their more complex modification - inverters.

In any case, the welding machine must have several operating modes, the choice of which depends on the type of electrodes used, and on the type and thickness of the metals being welded. The quality of the weld, which determines the reliability of the pipe connection, ultimately depends on the choice of welding mode.

Tip! The implementation of the welding mode recommended by GOST is carried out by selecting the electrodes of the required diameter and setting the optimum values of the current strength and voltage values acting in the electric arc.

All data on these parameters can be found in the relevant sections of the GOST on the welding of pipe metal products of a specific diameter.

Arc welding features

The essence of this process lies in the formation of welding equipment in the contact zone of the electric arc, under the influence of which the electrode rod melts. In this case, the metal drops in the slag shell are mixed with the molten material of the welded blanks themselves, after which the slag ascends in the liquid state.

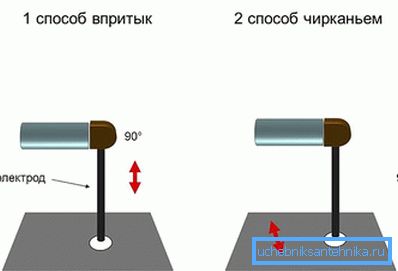

Features of arc welding are manifested in the following important points:

- the ignition of the working arc occurs at the moment when the end of the electrode only slightly touches the surface of the contact being welded;

- when working with pipe products, it is necessary to closely monitor the length of the arc, since the size of the gas envelope protecting the welding zone from the ingress of air depends on this parameter;

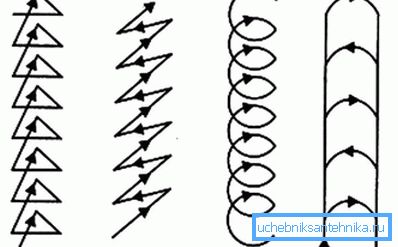

- to evenly melt the metal along the seam, the movement of the end of the electrode along the welded zone should be as smooth and uniform as possible;

- The thickness of the metal fusion on the seam is determined by the brand of tubular products and is regulated by light sliding movements of the electrode from side to side throughout the welding of the entire seam.

Tip! When joining thick-walled large-diameter pipe blanks, both external and internal seams should be formed.

Welding procedure

Before the start of welding, it is necessary to carry out all the preparatory measures provided for in the regulations, which include:

- cleaning the surface of the workpieces from the remnants of dirt and grease produced using standard procedures;

- alignment of pipes at the junction in one way or another (by laying under them small wooden bars of appropriate thickness, for example);

- selection of the required welding mode, as well as suitable for these purposes electrodes.

Tip! There are several ways to dock pipes, which differ in the width of the welded zone, as well as in the type of seam being obtained. In the case we are considering (when welding pipes of a pipeline), it is preferable to use the classical joint “end-to-end”, which allows boiling edges along the entire area of their connection.

Before starting work, you first need to turn on the welding unit with a cable already attached to it, equipped with an electrode holder, and then fix earth contacts on the workpieces.

After this, several short welds (tacks) are applied around the circumference of the jointed workpieces, ensuring the final fixation of their relative position, after which it will be possible to proceed to direct welding using the well-known rules (see “Features of arc welding”).

In the course of work it is always necessary to remember that pipe joints should be welded in continuous mode (without stopping) with simultaneous control of the constancy of the speed of movement of the electrode.

The number of welds applied during welding depends on the wall thickness of the blanks themselves; at the same time the first (main) seam is considered basic. After its application, it is necessary to check the quality of the resulting compound, and then knock down the slag formed on the surface with a metal hammer. Note that the latest seam should be applied as evenly as possible.

In conclusion, we recall that when working with welding equipment, it is necessary to use a protective mask and a special suit made of dense fabric, which reliably protects the exposed parts of the body from accidentally falling drops of molten metal on them.

Video

This video shows how to insert a pipe into a pipe of the same diameter: