Metal gutter overview

Water destroys the foundation and the blind area if it flows down unorganized from the roof. So, you need a drainage system for proper removal of water. There are two options: plastic and metal gutters. In this article we will consider the features of the latter.

The advantages of metal drainage systems

Metal drainage systems have a lot of advantages, among which it is necessary to highlight:

- affordable cost;

- ease of installation;

- presentable appearance;

- increased strength;

- resistance to both low and high temperatures.

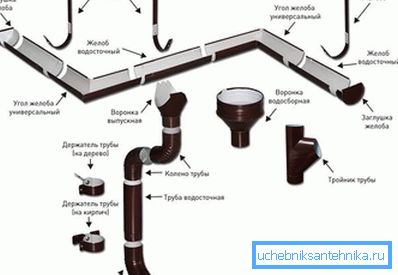

Construction drain: elements

The metal drainage system consists of gutters, corner elements, drainpipes, a collar, through which the chute and drainpipe are connected, and its knees are designed to change the direction of water flow, mark and plugs. In addition, the drainage system can be equipped with a grid that protects against the ingress of debris.

Swedish and Finnish water drainage systems are popular with us; Metallprofil gutters should be distinguished from domestic manufacturers.

Types of metal drainage materials

Drainage systems are made from different metals, which affects consumer quality.

Steel. Obtained by melting iron with carbon. Characteristics depend on the ratio of components. They are characterized by long service life, resistance to mechanical loads. Of the minuses should be noted the high price, corrosivity.

Galvanized. Zinc coating can be applied to the metal, which makes it rustproof. This increases the operational life of the drainage system. Such systems are cheap, however, the coating is rapidly destroyed by mechanical action.

Additional gutters may be covered polymer film, for example, plastisol, polyester (not as high-quality as the others, prone to scratches), pural from one or both sides. This gives:

- resistance to corrosion and water;

- UV protection;

- color variations;

- greater surface smoothness or texture from the outside.

Tip! During installation, operation, as well as cutting gutters, pipes, polymer and galvanized layer is damaged, spalled, scratched. In these places, if not properly protected, corrosion will occur, which will damage the system. The system can be damaged even when snow and ice melt from the roof.

Alumotsinkovye. Alumotsink is an alloy of zinc and aluminum. 2–3 times more resistant to corrosion than ordinary zinc. The color holds steady.

Copper. Perhaps the best and most presentable option. Most often made from pure copper, but sometimes they take alloys. The material does not corrode at all. However, such a drainage system weighs a lot, which means it can put a serious load on the foundation, therefore it is not suitable for weak foundations. In general, copper gutters are best used for houses that are made of durable materials, such as bricks. In addition, for installation, you need to hire professionals.

Aluminum. They are durable, but incompatible with other metals and may burst when bent, if the thickness of the metal is insufficient. The optimum thickness is 1–1.5 mm. On both sides, they can be coated with polymer powder paint. Prices for aluminum gutters are affordable.

Zinc Titanium. Plastic material. Systems from it will serve for a long time. Under the condition of sufficient thickness, they are durable (the thickness of the drain should not be less than 0.6 mm). Contact of drains made of titanium-zinc with iron and copper should be avoided.

Section shape

The shape of the section metal gutters are also different. Can be round, square, rectangular. Rectangular and square are more capacious, and the first more, and have greater rigidity. Round less roomy, so they decided to use for private homes. However, they have less resistance to the flow of water and debris due to the absence of corners.

Tip! It is important to choose the right diameter. It depends on the average annual rainfall, roof area, the number of craters.

Systems can be open and closed, hidden, external and external.

The gutter connectors should be selected with a stiffener and a sealing gum.

Installation

Brackets for fixing gutters at a distance of 60–90 cm from each other are attached to the eaves board or rafters. In this case, long brackets are used. If the roof is already laid, the brackets are fixed on the frontal board, and then take the short brackets. It is important that the brackets are of sufficient thickness (at least 4 mm), this will ensure the strength of the system. With a gutter length less than 10 m, the slope is made in one direction, if more - in two directions.

Self-tapping screws or hardware can be used, and between the fastener and the hook it is best to install a gasket so that the metal is not scratched.

Consider the installation of metal drain on the example:

| Holders are installed before mounting the eaves strip and roofing. Each bracket must be numbered and marked with a slope (3-4 mm per 1 m). |

| Then the bracket must be bent. |

| The bottom board of the batten is laid out every 50–60 cm, marking the locations of the brackets. Secure screws. |

| Markers are made on the gutter and a V-shaped hole (10 cm) is cut under the drain funnel using a hacksaw or other suitable tool. |

| Chutes are cut and secured with holders. Install plugs on the ends of the gutters. |

| Install the funnel, starting at the outer edge. Fix it holder for the rear edge of the gutter. In the funnel to protect against clogging set "spider". |

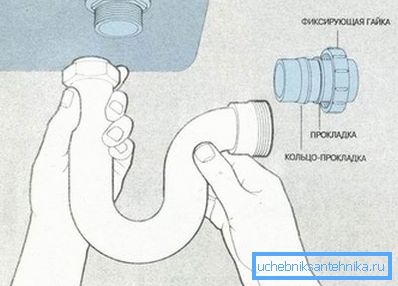

| The gutters are interconnected with an overlap, necessarily fixing the place with a connector with a rubber gasket. It is fixed, starting from the inner edge of the gutter and tightened with a lock. |

| Then install the cornice strip so that it overlaps the edge of the gutter, secure with screws to the crate of the roof. |

| A SP-1 connecting tape is glued on top of the strap, then a waterproofing film is removed from under the penultimate batten board and glued to the tape. |

| Where the flow of water may be too intense, set a limiter overflow. |

| Install holders (1 clamp per 1 meter of pipe). Clamps of different designs are designed for wooden and brick walls. |

| Set the knee on the outlet funnel. In clamps fix the drain pipe. |

| The funnel is connected to the drain pipe with the help of two elbows and a connecting pipe, the length of which is specified by location. The cut must be treated with enamel for polymer coatings. |

| The pipes are finally fixed with locks. |

| Below set drain knee at a distance of 30 cm from the blind area. The diversion of water can be organized into a closed or open storm system, or simply off-site or into a tank. Water can be used for irrigation. |

In this article, the types of metal gutters, as well as installation technology, were discussed in detail. We hope this information will help you make the right choice and carry out an independent installation of the system.