Metal pipe: a comprehensive analysis of the material and its

Metal pipes according to GOST can be used to solve an extremely extensive list of engineering problems. This is due to their good performance, as well as an extensive range of products manufactured by modern industry.

In the framework of a small review article it is impossible to tell about all the nuances of the production and use of such products, however, we will try to give a general concept of what are metal pipes.

Specifications

Production technology

The document regulating the technological processes in the manufacture is GOST for metal pipes. To be perfectly accurate, there are several such GOSTs, depending on what kind of shape we need and what material we will make it from.

Depending on the raw materials used pipes are:

- Steel - the most common.

- Cast iron - used mainly for laying sewage.

- Copper pipes - have good thermal conductivity, because of them make the elements of heating and air conditioning. Also, the instruction allows the use of copper in the installation of water pipes.

- Brass pipes - have a low tendency to corrosion, are used in water supply systems.

In addition, in some cases it is possible to manufacture pipe rolled products from non-ferrous metals, but the price of such products will be much higher than that of ordinary products.

There are also several production methods:

| Technology | Process features |

| Molded | According to this scheme, cast-iron products are produced, as well as fittings for metal pipes (adapters, fittings, elbows, etc.). The molten raw material is poured into the mold, from where it is removed after cooling and is subjected to finishing treatment. |

| Seamless | The pig is heated, stitched on a special press, and then goes to the rolling mill. Rollers of the rolling mill widen the hole from the firmware, thinning the pipe walls and extending it to the required size. The metal corrugated pipe before finishing is crimped in a special form, where ribs are applied to its surface. |

| Welded | The metal sheet of the corresponding brand is dissolved into strips. Then the strips fall on the molding, where one of them is the pipe. At the final stage, the edges of the strip are welded, and the protruding weld is cut off. Depending on the configuration, separate the longitudinal and spiral pipes. |

Main settings

Depending on the shape of the section, these types of metal pipes are distinguished:

- Round

- Profile

The latter category includes square, rectangular and other products that are used to solve specific problems.

Other important parameters include:

- Diameter (for profile - section or aspect ratio).

- Length (relevant only for piece varieties, since some models are supplied in coils under the cut).

- Wall thickness

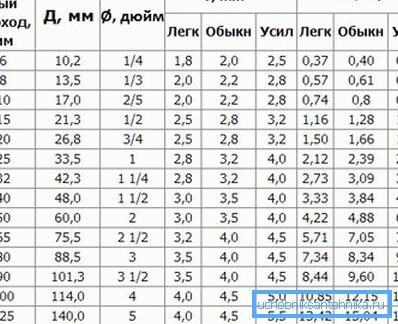

These parameters can be very different, and most of them are contained in the corresponding State Standards. In the article we will only give a few examples in the form of extracts from these documents.

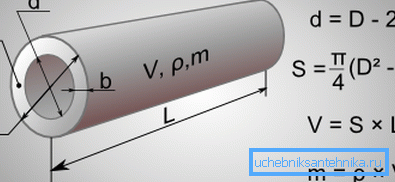

In principle, knowing these parameters, you can calculate the mass of the pipeline. How to calculate the weight of a metal pipe of circular section with your own hands - we will tell below.

The formula is as follows:

M = (D –T) * T * 0.025, where:

- M - specific weight, kg.

- T - wall thickness, mm

- D - outer diameter, mm.

- 0,025-coefficient for steel round products.

Note! For a square tube, this figure is 0.32, for a rectangular tube it is 0.16.

A corrugation has a rather complicated configuration, because its weight is usually not calculated, and for calculations use a tabular value. The same applies to other products of a special form.

Benefits

The advantages of such products largely depend on the material from which the part is made. And yet there are common characteristics of different products.

Among them:

- High mechanical strength.

- Ability to handle simple tools.

- The possibility of arranging hermetic connections.

- The durability of the product.

- A wide range of parts, allowing you to choose the element for any design.

- Reasonable cost (excluding extremely high-tech varieties).

Scope of application

The list of tasks for which pipe products are used is very extensive:

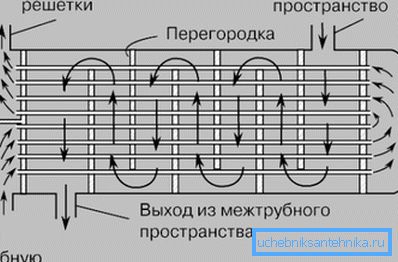

- The thinnest round pipes of thin copper or aluminum are used in the production of heat exchangers in hot water supply, heating, cooling and air conditioning.

- Pipes of larger diameter - up to 40-50 mm - the main raw material for arranging water pipes. They can also be used for the installation of gas pipelines.

Note! This applies only to private networks - for highways, varieties with a cross section of up to a meter or more can be used.

- Profile pipe - a universal building and finishing material. Frames are made of it literally for everything that needs support: furniture, small architectural forms (sheds, gazebos, stops), greenhouses, summer houses, etc.

- Also, the profile tubes are used as beddings for equipment, of which the vehicle frames are assembled, and the technological devices are assembled.

- We should also mention the piles of metal pipes: they can be either small (for country houses and other light buildings) or gigantic (for apartment buildings).

Note! In order to prevent deformation and impart necessary rigidity to the cavity of pipes, in this case it is better to fill it with concrete.

Conclusion

Of course, you obviously will not use the entire range of metal pipes in your work - these details are too different. But to get acquainted with the main types of costs, and for this we first recommend to watch the video in this article.