Metal pipes for plumbing is still a worthy competitor to

With the advent of the PP pipeline, many rushed to put an end to metal-plastic pipes, the reality turned out to be somewhat different - metal-plastic still remains popular. The proposed material will deal not only with the comparison of pipes of different types, but very specific issues will also be considered, for example, how to install metal-plastic pipes for water supply.

Features of metal-plastic pipes in comparison with metal and polypropylene analogues

At the moment, metal (steel or copper) pipes fade into the background, and the whole question boils down to what to choose - metal-plastic or polypropylene pipes for plumbing.

Several factors speak in favor of the metal-plastic pipeline:

- durability, depending on the manufacturer, the guaranteed service life can reach 30 years;

Note! If the manufacturer has indicated a service life of about 25-30 years, this does not mean that the water supply will have to be changed after this time. They can serve for 40-50 years, it all depends on the operating conditions and compliance with installation technology.

- DIY installation of plumbing pipes made of metal pipes is extremely simple. Polypropylene, however, is also not very difficult to install;

- strength even with substantial heating is higher than that of PP;

- metal pipes can be bent, As a result, the installation reduces the need for fittings, and due to the smooth bends and resistance to water flow is minimal;

- the inner surface of the material is almost perfectly smooth, friction losses are minimal;

- pipes made of this material can survive even water freezing inside without damage, although, of course, it should not be brought up to this;

- they are not afraid of corrosion, but from the inside it does not “overgrow” with time, as it happens, for example, with steel analogues;

- the cost of metal pipes for water supply is low. The cost of 1 running meter does not even reach 100 rubles;

- the high operating temperature allows them to be used to supply both cold and hot water. As for propylene, for metal-plastic, the limiting operating temperature can be considered as approximately +95? С and a pressure of about 10 bar.

However, this material has several disadvantages:

- with excessive bending, the wall may simply burst;

- if the pipes themselves freeze the water without problems, then the metal fittings for pipes that are used during installation will most likely have to be changed;

- the material is not resistant to oils and aggressive chemicals, it somewhat narrows the scope of its use;

- a different coefficient of linear expansion of materials used in the production, in some cases, can lead to delamination, that is, the layer of glue between the layers of plastic and aluminum is destroyed due to temperature stresses.

More information about the metal-plastic pipeline

The listed strengths and weaknesses give only a general impression of this material. In order for the gaps to remain, it makes sense to consider in more detail plumbing pipes.

The structure of the metal pipe, its types

The key difference of the metal-plastic pipe from the metal or propylene is in that it consists of separate layers glued together. This is both its advantage and disadvantage.

In a section the metalplastic pipe will consist of 5 layers. In the center there is a layer of aluminum foil (it is precisely its thickness that determines the ease of bending and the strength of the wall). On both sides, in production, the foil is coated with adhesive and a layer of cross-linked pex-b polyethylene is glued to it (inside and outside).

Note! The optimum can be considered a foil thickness of about 0.3 - 0.5 mm. In this case, the installation of plumbing from metal pipes will not cause much difficulty, they will bend easily, while maintaining sufficient strength.

The described structure of the wall is the same for all metal-plastic pipelines, and the differences are mainly in the method of crosslinking polyethylene, the material used, the working pressure, etc.

All these data can be obtained simply by looking at the marking of the pipeline:

- polypropylene (PP-R), polyethylene (PE-R) and cross-linked polyethylene (PE-X) can be used;

- the stitching method is marked as follows: a - pyroxide; b - using silane; c - using the energy of a directed electron beam; d - with nitrogen. The price of pipelines is not very different depending on the method used;

- operating pressure;

- it further states what exactly can be transported (drinking water, technical liquids, etc.);

- at the end is the batch number.

As for the sizes, the most popular diameters are 16, 20, 26, 32, 40 and 50 mm. The wall thickness varies from 2 mm (for diameters of 16 and 20 mm) to 5 mm (for diameter of 50 mm).

The inner diameter of metal pipes for water supply can be determined by taking away from the diameter of the outer double wall thickness. For distributing water to the apartment usually do not use pipes with a diameter greater than 32 mm.

Connection methods

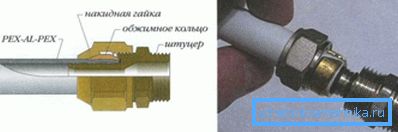

If in the case of polypropylene pipes soldering can be used, the metal-plastic pipe is usually laid using either press fittings or compression fittings. Only the technology is slightly different, the plumbing fittings for metal-plastic pipes are made of metal (brass).

The order of work at the pipe connection is somewhat different:

- in the case of press fittings, a sliding sleeve and a flare is used, this joint belongs to the one-piece class. Also, the connection can simply be pressurized;

- Compression fittings can be disassembled if desired, but experts advise to change the fitting entirely. That is, the category of plug it can be attributed.

Another feature of the connection of plastic pipes can be called the fact that the joints should be left open. Even if the technology was observed, the risk of leakage still remains.

Work execution technology

As for how to connect metal-plastic water pipes, it is difficult to give preference to any one method, therefore we will consider both.

In the case of compression fittings, work is performed in this order:

- after marking the pipe is cut, the burrs are cleaned. Also, the chamfer is removed at the end of the pipe, calibration is performed to restore the section geometry;

Note! It is better to use special scissors or cutter for cutting. Of course, you can cut off and ordinary sawing for metal, but there is a risk of deformation of the pipe.

- the fitting is lubricated; a cap nut and a split ring are put on the pipe (in that order);

- the prepared pipe is put on it. For the tightness of the joint, it is very important that the end of the tube be flush with the flange on the fitting;

- after that, the union nut moves in and twists first with the hands, and then with the key. It is important not to overtighten the connection, if you do not have a torque wrench, you can be guided by the fact that with the nut tightened until it stops, about 1-2 thread threads should remain visible. A water pipe made of metal-plastic pipes with their own hands, taking into account the listed installation rules, is guaranteed to last for a long time.

If a press connection is used, then only press pliers will be needed. The tube is inserted into the fitting all the way (you can navigate to the control windows). Then the metal part of the fitting is crimped by press-pliers and the tightness of the connection is guaranteed.

In the case of a sliding fitting, the instruction looks like this:

- the pipe is prepared as described above;

- the sliding part of the fitting is put on the pipe, flaring of the pipeline is performed;

- then it fits all the way onto the choke;

- after that, the movable part slides onto the tube with the help of special tongs. Due to the very strong compression is achieved tightness of the connection.

Summarizing

Metal-plastic pipes firmly hold their market share, high operational characteristics, their low cost and ease of installation contribute to this. And after reading this article, you know how to connect metal-plastic pipes for the water supply system independently, and the work on the arrangement of the water supply system will not cause any special difficulties.

The video in this article shows several options for joining metal-plastic pipes.