Metal pipes for ventilation - types and characteristics

In the interval between the 60s and 70s of the last century, the industry offered only ventilation boxes with a rectangular section, and only a few years later the range expanded with ventilation pipes. Before the 1990s, the process of standardization of product diameters began, which allowed to unify the details, due to which the assembly of any type of system was simple and efficient. Today we will discuss metal ventilation pipes - their types, advantages and features.

Duct materials

For manufacturing today use a variety of materials that differ:

- value;

- reliability;

- ease of installation;

- ease of operation and maintenance.

Most of the others acquire metallic, the shape of which can be round or rectangular.

One of the most important properties are:

- ability to resist corrosion;

- fire resistance.

Typically, these characteristics have ventilation channels made of titanium and stainless steel, but the price of such products is quite high. It will also be good when the surface of the product is protected by a fire resistant coating.

| Titanium |

|

| Metal |

|

Advantages of stainless ducts

- Do not need additional decorative finishing, especially when mirror stainless steel is used.

- The material is harder than steel, it is more than 6 times more heat resistant (the working temperature can be up to +900? C, whereas in galvanized steel it is up to +140? C).

- The stainless steel also exceeds the black or galvanized steel several times in wear resistance, moisture resistance and biological resistance, due to which its operating life is much longer.

- The polished surface of the products does not allow for the rapid accumulation of grease, dust and soot on it, allowing for an increase in service intervals and less frequent cleaning of air ducts and their disinfection.

- Due to the high heat capacity of the material, such air ducts do not require pre-heating, so they are used to divert hot air from stoves, boilers and fireplaces.

- Simple mechanical machining of air ducts with their own hands enables them to be easily customized “at the place” of work, which makes them even easier to install.

We recommend using stainless air ducts when installing ventilation in an open way, when the customer needs to see not only the quality of the products, but also their flawless appearance. Such products are also often used in places where there is an aggressive environment.

Consider below, in which areas are most often used stainless ducting:

- at the chemical and pharmaceutical enterprises;

- in the food industry;

- in the manufacture of cosmetic products;

- in medical institutions;

- at catering establishments, in bars, cafe and restaurants.

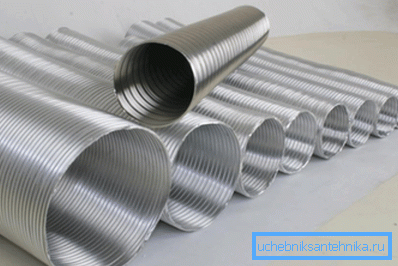

Flexible and semi-flexible ventilation pipes

In addition to rigid ducts made of steel, flexible and semi-flexible products made of aluminum foil can now be purchased. The latter are very easy to transport, since they can be compressed as an "accordion", and during installation work, restore the length.

If for the manufacture in this case using thick aluminum foil, flexible products are made from thin. Also used polyester film stretched on a frame of metal wire.

From the advantages of flexible structures, we can distinguish them:

- ecological purity;

- security;

- durability.

In addition, the cost of installation of flexible structures is lower than the installation of rigid blowers.

Tip: if you want to get rid of the noise during the operation of the ventilation system, purchase flexible products insulated with a layer of mineral wool.

Among the shortcomings - high aerodynamic drag, not too aesthetic appearance.

Choice of duct diameter

There are several factors that must be considered when selecting the diameter of the ventilation duct:

- floor space;

- pipe placement relative to ground level;

- purpose of installation

The instruction recommends choosing vent pipes with O 90-140 mm for the basement or cellar, which is the optimal solution. You will have the necessary temperature in the room, and high-quality ventilation will remain. A larger diameter can create problems in operating the system.

Tip: if you are in doubt about your choice, it is better to ask for help from the sales assistants. This will provide an opportunity to save time and money.

Conclusion

The range of metal ventilation pipes today is quite wide. Products may vary in materials, shapes and appearance. Thanks to this, you can always choose for yourself exactly what you need and at an affordable price. The video in this article will help you find additional information on this topic.