Metal rectangular tube: variations and main technical

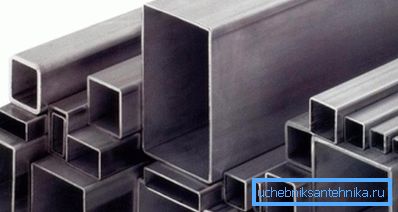

Profile pipes are a model of strength and reliability. They are very widespread in almost all construction areas. In this article we will examine a few important points concerning such demanded products.

Everything you need to know about shaped tubes

Perhaps we should start with the definition: a rectangular tube is a hollow metal profile, which is specially produced in the factory by cold, warm or hot rolling. The resulting stiffeners give this product an incredibly high strength, taking on any pressure exerted.

Benefits

- Very high strength characteristics, the reasons for which we have already mentioned. Allow to withstand huge loads.

- Convenient for storage and transport form. Rectangular products are much more compact folded.

- Relatively low price, which is due to the metal savings in the manufacturing process.

- A wide range of sizes and shapes of sections, as well as wall thickness.

- Application in various fields:

- Construction of houses, arbors, greenhouses from pipes, pavilions.

- Fences, awnings, railings and other various auxiliary or design structures.

- Plumbing and interior elements.

- Agricultural machinery.

- In the furniture industry.

- Easy to do it yourself. Thanks to strict geometric shapes, the products in question easily fold into the desired structures.

- Long operational life.

Tip: in the case of using steel products, do not forget about additional treatment with antiseptics or painting. This will protect them from corrosive processes, which will significantly prolong their service life.

Types according to the production process

There are several possible uses of various technologies to obtain the desired shape of the metal product in question:

| Species name | Special features |

| Hot rolled seamless | Resistance to corrosive processes and chemically aggressive media |

| Cold rolled profile | Increased strength, elasticity and ductility |

| Profile electrowelded and cold-formed electrowelded | Simplicity and relatively low manufacturing cost |

Tip: for the construction of dimensional metal structures, it is recommended to choose cold-rolled profile models. Due to their higher strength properties and resistance to atmospheric pressure, they are best suited.

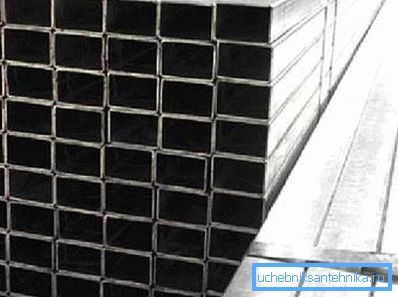

Views according to material used

The most common products are:

| Type of | Character traits | Regulatory Document |

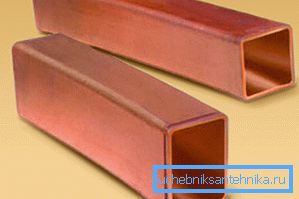

| Copper | No corrosive processes, elasticity, attractive appearance, high cost and some softness | GOST 859-2001 |

| Aluminum | No corrosive processes, light weight, easy handling | Range of aluminum rectangular pipe in accordance with GOST 22233-2001, 8617-81 |

| Steel | Increased strength and resistance to mechanical stress, susceptibility to corrosive processes | GOST 13663-86 |

We should also mention about galvanized products, which are subspecies of steel models, but are additionally protected by a zinc layer that protects against the appearance and spread of rust. Although they are more expensive, but their advantages are obvious.

Make a choice depending on the pursued goals and financial capabilities. That is, if it is, for example, a part of a home interior, then it may be worth spending money on copper. But for a greenhouse, galvanized steel or ordinary steel is perfect.

Flexion

Often there can be such cases when it is required not a straight pipe, but a curved one. What then to do with such a strong product? After all, the stiffeners will not be allowed to bend by hand, as could be done with a model having a normal circular cross section.

Of course, the most obvious and simple solution will be the use of special machine equipment, but if this is not at hand, what is most likely to happen in a country cottage? In such a situation can help you sand or "Bulgarian".

Instructions for the use of sand:

- We hammer a wooden cap on one side of the product.

- Tightly we fall asleep inside clean dry river sand.

- We plug the second side with a plug.

- The sand in the pipe distributes the pressure evenly around the entire perimeter of the product..

- We are gnawing like a normal pipe with a round section.

- Remove or burn out the plugs and pour out the sand. Is done.

With the use of an angle grinder, the situation is faster, but less filigree:

- In the area of the future corner, we make cuts from the side into which we will bend the part. In this case, there should be two notches along the edges of the deformable segment.

- We are chasing the pipe at the required angle.

- We make cuts, after which the product can be installed.

Conclusion

If you need to build a solid structure of any size, rectangular pipes will cope with this task in the best way. They are also used in engineering, furniture manufacturing, plumbing, decoration and many other construction fields.

Such products are distinguished according to the method of production and according to the material used for this purpose, which allows choosing the model that is optimally suitable for the specific task.

The video in this article will introduce you to additional materials.