Modern pipes for the furnace: the main types, features of

Heat-resistant pipes for furnaces are designs with a long history. The operation of chimneys throughout the world dates back several centuries, during which these devices were structurally modified and improved.

Over time, the pipes were made of different materials, the choice of which was determined by the requirements for a particular modification of the chimney. In this article we will talk about the most common types of chimney, the features of their operation and methods of maintenance.

Main varieties

Before we talk about what the instruction manual for the use of furnace chimneys, consider what their main types are and how they differ from each other. Chimneys, first of all, are classified according to the type of materials used in the production.

Currently, modifications made from:

- fireproof brick;

- ceramics;

- metal;

- asbestos cement;

- other materials.

Consider the features of these modifications in more detail.

Brick pipes

Chimneys made with the use of refractory bricks are widely spread throughout the territory of the Russian Federation.

Traditionally, these structures consist of the following structural elements:

- the neck through which the connection is made to the furnace;

- smoke valves;

- riser;

- otter;

- slope;

- neck;

- headband;

- cap

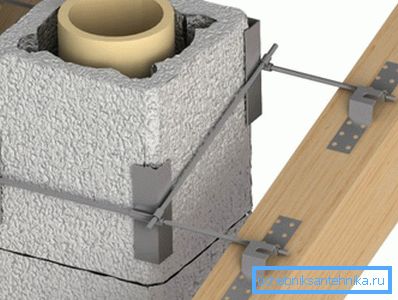

Important: When constructing chimneys, it is necessary to take care of high-quality thermal insulation in the places of junction with the ceiling and roofing system. The choice of thermal insulation materials is based on the requirements of fire safety standards.

As a rule, the construction of brick pipes is carried out with the construction of the building. The construction of such structures in an already operated construction site entails additional difficulties (dismantling part of the ceiling and roofing system).

Among the advantages of brick structures, we note, first of all, high efficiency, since the draft in a properly constructed chimney is excellent, while most of the heat remains inside the furnace. In addition, the durability and ease of repair work can be attributed to the advantages of such structures due to the possibility of replacing bricks that have become useless with their own hands.

However, there are drawbacks:

- Brick chimneys can not be used with all types of heating devices.

- The construction of these structures is carried out exclusively by professionals, and therefore the price of the finished result is high.

- The internal volume of a pipe assembled from a brick is a relief surface, which contributes to the accumulation of soot and the occurrence of blockages in the pipes.

Ceramic chimneys

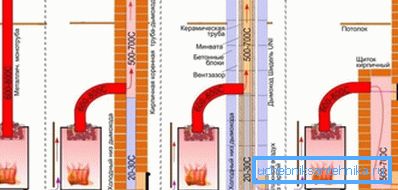

This is a relatively new technology that is becoming more common. Structurally, the ceramic smoke exhaust system is a three-layer structure.

By itself, a round pipe made of ceramics is not used on its own, but installed inside a protective case made of expanded clay blocks. The space between the outer contour and the pipe is filled with refractory material, as a rule, mineral wool based on basalt fibers is used.

Among the advantages of such facilities, we note the following:

- the possibility of location of the structure, both inside and outside the building, which is more than relevant if the furnace is built in an already operated house;

- smooth inner surface and, as a consequence, the absence of accumulation of blockages;

- less weight compared to brick counterparts and, as a result, less stress on the structural elements of the construction site;

- long operating life subject to proper installation;

- high degree of fire safety due to the use of a three-layer construction;

- better thrust compared to brick pipes;

- possibility of use with most modern heating units.

Of course, there are disadvantages, among which are:

- high price;

- the complexity of the installation work;

- the possibility of positioning the chimney only in a vertical position.

Metal chimneys

Today the metal pipe for an oven in the market is presented by two main types:

- modifications in galvanized steel;

- stainless steel modifications.

Both categories are durable, reliable and feature many operational advantages. But, if we take into account the fact that the combination of critically high temperatures and the composition of combustion products contributes to the development of corrosive processes, it is advisable to choose modifications made entirely from stainless steel.

Despite the fact that the price of stainless steel products is an order of magnitude higher than the cost of analogues made of galvanized sheet steel, this difference is compensated for by an almost unlimited resource.

Among the advantages of stainless steel chimneys, we note the following:

- small weight of a design, in comparison with brick and ceramic analogs;

- ideally smooth inner surface, which reduces the likelihood of blockage;

- ease of installation work due to simple metal machining;

- reasonable price, in comparison with ceramics;

- low weight of the entire structure and low mechanical load on the construction site;

- the possibility of assembling chimneys of various configurations, both with vertically arranged and with horizontal elements.

Important: For the full operation of metal chimneys, it is necessary to apply a layer of insulation that will ensure that the system complies with fire safety regulations.

Constructions from other materials

In addition to the above modifications, it should be noted products from asbestos cement. Such pipes have two main advantages, among which, reasonable price and a wide range of sizes available on the market.

However, there are an order of magnitude more disadvantages, since such chimneys are not strong enough and the impact of critical high temperatures can lead to their cracking. No less significant drawback is the inconsistency of asbestos cement with environmental safety standards.

In addition to asbestos cement, other materials are used, such as hot glass. But such products are not widely spread and are perceived rather as exotic.

Important: Regardless of which chimney is used, it is important to know when to close the pipe in the oven so as not to get angry. As a rule, this is done after the open flame in the furnace burns out and coals remain.

Preventive maintenance

Sooner or later, you will be faced with the question of how to clean the stove pipe in order to return the old cravings.

Regardless of the type of chimney used, a blockage occurs over time. As a result, the intensity of the traction of the heater is reduced, and in some cases a certain amount of smoke can penetrate inside the room.

So let's find out how to clean the pipe in the stove with available means.

To date, there are two known methods for cleaning clogging in a chimney:

- mechanical method based on mechanical removal of combustion products from the pipe;

- a chemical method based on the use of a number of reagents that act on soot and ash, and thus contribute to their destruction.

Important: Experts are of the opinion that the above methods provide the best result when used in combination with each other.

During mechanical cleaning a number of the following problems can be fixed:

- obstruction by foreign objects (foliage, bird nests, etc.);

- contamination by combustion products (soot and ash);

- accumulation of acid condensate on the inner surface of the pipe.

Chemical cleaning is an order of magnitude simpler than mechanical maintenance, but the result of using reagents is short-term. Therefore, the burning of special logs or the use of such tools should be performed at least once a month.

Conclusion

Now you know what types of chimneys are commonly used, and what advantages and disadvantages are inherent in each individual type. In addition, we considered the features of the use of chimneys and their periodic maintenance.

More useful information you can find by watching the video in this article.