Non-pressure pipes - we study all types and their features

This material has long been very popular in the field of both civil and commercial construction. This is a very important element, so its production is subject to strict control. There is a GOST 6482 88 for reinforced concrete free-flow pipes, which regulates the quality of these products.

There are three types: reinforced concrete, asbestos cement and polyethylene. Each of them has many features that you need to know. All this we will tell you further.

Reinforced concrete

Non-pressure reinforced concrete pipes are the most common in this segment. They are most often used when laying various communications. Also recently they have been used in private construction.

general description

Such products are made of weighted concrete of high grade with reinforcement. It gives special strength to structures.

These bell-shaped reinforced concrete products are used in many areas of construction, from civil to industrial. They are also often used to organize storm sewer systems, etc. They divide non-pressure reinforced concrete pipes according to their carrying capacity.

To date, there are five groups:

- The maximum depth of embedding in the ground is not more than 2 m.

- 4 m.

- 6 m.

- 8 m.

- 10 m

Merits

Obviously, if a product is widely popular, it must have certain reasons.

In particular, free-flow bell-shaped pipes have an impressive list of positive qualities:

- Highest strength.

- Durability. The service life, if fully complied with the method of production, is practically unlimited.

Interesting: the fact is that under their own weight they begin to undergo a natural pressing, which provides increased strength.

- Water resistant (W4-W8).

- Frost resistance (on average about 200 cycles).

- Water absorption not more than 5%.

- Affordable price.

- Simplicity and high speed of installation

Marking

When purchasing a particular material, you should pay attention to the labeling. It is better than any instruction can tell about it.

The marking consists of letters and numbers, where (from left to right):

- Type of pipe (TB, vehicle, etc.).

- Inner diameter in centimeters.

- Useful length in decimeters.

- Type of bearing capacity.

- Sometimes at the end there may be the letter "y" - this indicates the presence of a thickened wall. If there is none, then it is absent.

Knowing this, you can get detailed information about the purchased product.

GOST

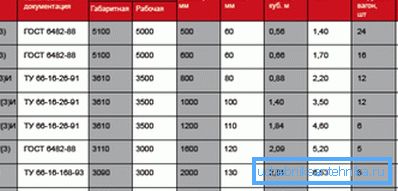

There is a GOST regulating concrete pipes. It controls the dimensions and some specifications. Therefore, before going to the store, it is desirable to familiarize yourself with such information.

| Conditional pass (cm) | Radius (cm) | Thickness (mm) | Length (cm) | Minimum crush load (N * (kc * s)) | |

| External | Interior | ||||

| 100 | 5.9 | five | 9 | 295; 395 | 4508 |

| 150 | 8.05 | 7.05 | ten | 295; 395 | 3920 |

| 200 | 10.55 | 9.45 | eleven | 395 | 3136 |

| 300 | 15.35 | 13.95 | 14 | 395 | 4116 |

| 400 | 20.1 | 18.4 | 17 | 395 | 4900 |

Note that small deviations in dimensions are allowed (we are talking about the radius). Depending on the particular type of model, the allowable value may vary. Deviations can be from 1 to 3 mm.

It should also be noted that today not all manufacturers strictly comply with the technical conditions, so it is likely to find a product that is different in its characteristics. Therefore, when buying, ask the seller for a certificate of conformity.

Asbestos cement

For over 70 years, such products are in great demand in the construction industry. They are obtained by pressing cement and asbestos, which in the final result provides tremendous strength of the finished product. Their quality is controlled according to State Standard 1839 80.

They are applied in the following areas:

- Laying of water (both technical and drinking) networks.

- Pressureless sewage.

- Drainage collectors.

- Garbage chutes.

- Chimneys, etc.

Interestingly, in such developed European countries as Austria, Germany and Belgium, they are the most popular choice in the field of heat supply. This is due to the very low thermal conductivity and high corrosion resistance of this material. As a result, such systems can operate for more than 30 years, without any deterioration in quality.

You can not ignore the main advantages, of which quite a lot:

- Reliability.

- Resistance to many aggressive environments.

- High service life. So, for example, asbestos-cement free-flow pipe 300 in terms of use in a private house will serve at least half a century.

- Resistance to corrosion.

Interesting: their metal "brothers" fail after 5-10 years, due to the effects of corrosion. Therefore, in this aspect, asbestos cement looks like a clear favorite.

- Feels great in the ground.

- Weak hydraulic resistance.

You should also know and certain recommendations for use. If you decide to use the product described by us, they must be known without fail.

So pay attention to the following guidelines:

- The trunk must be laid with a slope of 2-3 mm per meter of length. The slope should go towards the well (or other water source).

- If the terrain has a sufficient natural slope, then you can arrange it evenly.

- For connection it is obligatory to use only certified couplings for sewer systems (GOST 1839 80). However, they must be cylindrical.

- The ends should be cut perpendicular to the axis of the pipe. After that they should be processed at an angle.

This is not all the requirements, because in fact they are several times more. They depend on the specific type of work.

Polyethylene

With the constant improvement of technology, plastic has become increasingly used in construction. In the field of private construction, this product gradually begins to crowd out its competitors.

This is due to its many advantages:

- Low cost.

- High service life (under normal conditions - up to 50 years).

- They do not require cathodic protection.

- Resistance to many chemically aggressive substances.

- Not afraid of corrosion.

- When freezing, such structures are not destroyed. This greatly reduces the risk of accidents during the cold hours of the day.

- Very small weight.

- Ecological purity.

- When working with them do not need to use any protective equipment. Therefore, it is easy to work with them with your own hands, even for inexperienced people.

Note! They can be operated under pressure of not more than 3 atmospheres.

The scope of use of such products is quite wide: hot and cold water supply (free-flow), sewage, water transportation, etc. They are produced with a diameter of 15 to 225 mm. Quality control regulates TU 2248-001-7272118-2004.

In conclusion

So you studied GOST for asbestos-cement non-pressure pipes, as well as many other equally important aspects. In the presented video in this article you will find additional information on this topic. Viewing it will add to the already wide range of knowledge.