Outer tube diameter - all you need to know about sizes

When it comes to the design of sewage systems, heat and water supply, one of the most important tasks can be called the correct selection of the pipeline. This refers not only to the material, but also to its size, in particular the outer diameter of the pipes.

What does the size affect

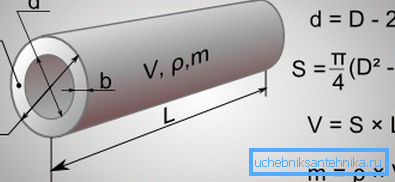

The main task of any pipeline is the transportation of liquid (gas), so one can briefly describe the principle of operation of any system in the house (sewage, heating, gas pipeline, ventilation, etc.). Accordingly, the main criterion for the effectiveness of its work is throughput, i.e. the amount of liquid or gas passing through the section per unit of time.

At the planning stage, usually take into account the outer and inner diameter of the pipe. Internal influence directly on throughput, and the difference between external and internal can be judged on the wall thickness, and hence on the strength.

This is especially important when designing heating systems, plumbing, because they work in the pressure mode. If you try to save on and use the pipeline for cold water in the heating system, in the near future it will have to be changed.

At first glance, no problems should arise, it is enough just to pay attention to the labeling. In reality, there are quite a few pitfalls in this matter, because not the metric, but the inch size designation system is often used.

Features of diameter designation

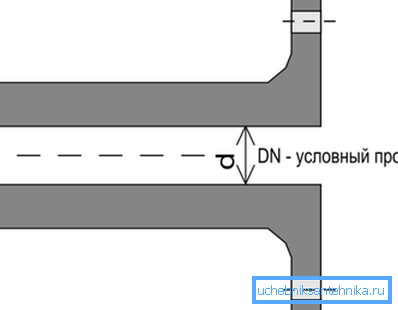

In addition to the dimensions specified in the usual millimeters or inches, the concept of nominal diameter is also used - in other words, the size of the lumen. Thus, innocent at first glance, the entry in the form of the outer diameter of the pipe Du25, initially carries a mistake, because the acronym DU is used exclusively as an internal dimension.

The same applies to the designation of the outer diameter of the pipe Du32, in this case, either the prefix "Do" or the word outer must be removed. Otherwise, the store can spend more than one hour trying to find a non-existent size.

Note! Using the value of Du, you can roughly estimate the throughput. Initially, they are selected so that each next value gives an increase in throughput by an amount from 60% to 100%.

When working with different materials, for example, when replacing part of the old cast-iron sewage to plastic. Instructions for the implementation of plumbing work, as a rule, focuses on technology, without paying special attention to the selection of standard sizes. Problems with different number systems can occur even among experienced craftsmen.

Polypropylene pipe

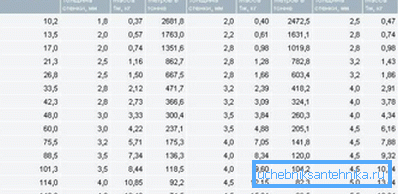

It can be used for installation of heating systems and plumbing. As a rule, a size in the range from 20 to 110 mm is chosen, although the latter is practically not used in private homes. The parameters of the finished product must comply with GOST R 52134-2003.

When choosing to take into account account for the outer diameter of polypropylene pipes. The fact is that the wall thickness differs depending on the brand. So, for the brand PN10, the outer diameter 32 will correspond to the inner diameter - 26.0 mm. And for the brand PN20, by increasing the wall thickness, the DN will decrease to 21.2 millimeters.

When choosing it is important not to confuse external and internal dimensions. So, if the question is whether a pipe diameter of 32 mm is required, external or internal, then it is most likely an external one. After all, Du 32 simply does not exist, the closest value is 32.6.

Note! If all the work is done by hand, it is better that all the elements are from the same manufacturer and from the same batch. Due to this, external and internal parameters will exactly match each other.

It is possible to cite averaged data on the most common PP pipes. So, for the installation of heating is most often used in the size range of 20 - 32 mm. the thickness of the heating pipes rarely exceeds 50 mm. (See also the article Types of sewer pipes and connections: features.)

Steel and cast iron pipes

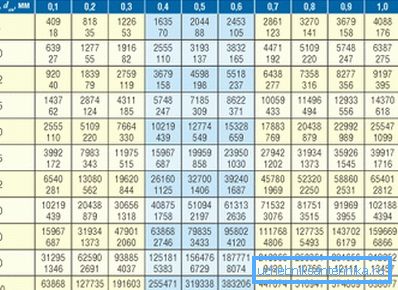

Within the framework of one article, it is simply impossible to mention all frame sizes, since there are hundreds of them, and they also differ depending on the mode of production:

- hot rolled pipeline. The standard GOST 8732-78 says that the outer diameters of steel pipes produced by this technology vary in the range of 20 - 550 mm (about 70 standard sizes). If we also take into account the inner, then you can select several hundred if not thousands of sizes, because you need to take into account the wall thickness;

- cold hire. GOST 8734-75 identifies more than 70 sizes, and the situation is the same as with hot rolled pipe analogs, that is, the wall thickness varies over a wide range.

Keep in mind the entire range, of course, not necessary. Enough to navigate at least in the most common sizes. It is good to keep in mind, for example, the inner and outer diameter of steel pipes, which are used to organize water supply.

But the main mystery for many is the decoding of inch designations. This is especially important if the connection is threaded, even a slight mismatch will not allow you to create a sealed joint, in the future this can lead to leaks.

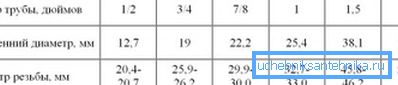

Knowing the marking in inches, you can judge the diameter of the thread and DN. Thus, the outer diameter of the pipe 3 4 says that Du is equal to 20 mm, threaded - 25.9 - 26.2.

As for cast iron, everything is much simpler, using 3 main sizes - 150, 100 and 50 mm. In this case, the conditional passage, that is, the Du pipeline, serves as the main criterion. In everyday life, cast iron is used to organize waste disposal, as a rule, the standard size is 100 or 150 mm.

VGP pipeline

The abbreviation VGP stands for water gas pipeline. Steel is used for production, and it can be used not only as a pipe for external plumbing, but also for laying a gas pipeline.

The full range of steel VGP pipeline is determined by the standard GOST 3262-75. The designation means internal, or rather Du, while knowing the thickness of the wall, it is possible to calculate the thickness of the pipeline. Thus, the VGP designation Du15 means that Du is equal to 15 mm.

The outer diameter of the steel pipe 22 mm allows you to compare it with the VGP Du15, because its thickness is 21.3 mm. But at the same time, the electrowelded analog has a much larger clearance (ranging from 18 to 20 mm, depending on the wall thickness). This difference is due to the operating conditions of the system.

Separately, it is worthwhile to consider inch designations of AIV pipelines. Here the relationship between the dimensions is as follows.

| Inches | 1/4 | 1/2 | 3/4 | 1.0 | 1.25 | 1.5 | 2.0 | 2.5 | 4.0 |

| Size in millimeters, DN | eight | 15 | 20 | 25 | 32 | 40 | 50 | 65 | 100 |

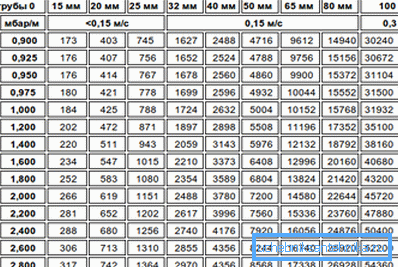

The outer diameter of the VGP of the pipe depends on the wall thickness; in total it is produced in 3 versions:

- lungs;

- ordinary;

- reinforced.

For example, when Du 40 in the range indicates Dn 48.0 mm. The wall thickness ranges from 3.0 (lightweight version) to 4.0 mm (reinforced version). Reinforced version is used for systems operating under high pressure.

Copper pipes

Despite the popularity of plastic, copper is still used to organize plumbing and heating systems (even if the price is higher). With regard to the designation of dimensions, then you can encounter the use of both inch and metric number systems. As for the standard, the product range is given in GOST 617-2006.

The new standard is based on the metric designation of dimensions, therefore, for example, the old 3/8 inch designation has been replaced by two sizes (6 and 7 mm). In general, only cold rolled products give about 70 - 80 standard sizes, and this if only thickness is taken into account.

When choosing the right pipeline, you may encounter the following size designations:

- inch In this case, the designation, for example,? inches will only indicate the outer size;

- fractional. In the 14/12 recording format, the number 14 shows the outer diameter and 12 indicates the inner diameter;

- fractional indicating the wall thickness, for example, 14/1. In this case, the number 14 indicates Dn, and 1 - wall thickness.

Summarizing

Within the framework of one article it is difficult to cover all the details of the marking of pipe rolled products. Nevertheless, the proposed information will help to navigate when choosing the right pipeline, which means that the risk of leakage will be minimized.

The video in this article shows an example of diameter selection based on the operating conditions of the pipeline.