Pe pipe - material features and various mounting options

Polyethylene pipes are high-tech products, thanks to which additional possibilities have appeared in the construction of pipelines of relatively small diameters (this also applies to the Pe 80 pipe). They can be connected to working water supply networks, both polymer and metal.

The use of polyethylene pipes in water supply networks has about 40 years, allowing you to significantly save installation time using specially designed equipment.

Characteristics of polyethylene pipes

PE 80 and PE 100 are currently the most popular brands. It is with their help that the pipelines are collected, through which the transportation of domestic or drinking water is carried out. In addition, they are actively used for the construction of pipeline networks for gaseous substances, because polyethylene is chemically resistant to gases.

PE pipes for water supply are made of low-pressure polyethylene, using the method of continuous screw extrusion. Thus it is possible to obtain reliable products that can safely be put into operation for a period of 50 years or more.

| The main applications of polyethylene pipes | |

| Application area | Type of product |

| Cold water supply | PE pipe water with high density |

| Hot water supply and heating systems | Products made of cross-linked polyethylene |

| Gas supply | Stamps, special labeling "gas" |

| Heated floors | Products made of cross-linked polyethylene |

| Drainage systems and PE pipes for sewage | Corrugated with perforation |

The main advantages of PE pipes

Consider a few major advantages that the PE pipe has:

- Cheaper analogues.

- Durable.

- They do not need cathodic protection, therefore they practically require no maintenance.

- High chemical and corrosion resistance, such products are not afraid of contact with aggressive media.

- On the inner surface is completely eliminated the formation of scale.

- Low thermal conductivity, due to which heat losses are significantly reduced, reducing the formation of condensate on the pipes.

- It is possible to perform multiple remounts at a relatively low cost.

- When a liquid freezes, the probability of pipeline destruction is extremely small, since the PE pipe in this case only increases in diameter, acquiring its previous size when the liquid begins to thaw.

- The relatively small weight of the PE pipe, thanks to which the installation work is greatly simplified and accelerated. For such products do not need lifting mechanisms, and one machine can transport an average of 7 times more such products than steel.

- Reliable welds, in addition, butt welding in this case is cheaper and simpler, taking significantly less time.

- Such products are not affected by bacteria and microorganisms. Their inner layer does not add harmful impurities to water.

- The low price thanks to which installation of PE pipes allows to save up to 40% of means.

Installation of pipes made of cross-linked polyethylene and its features

The active production of PE pipes and the low cost of these products have aroused some interest in low-temperature heating systems among private house owners. And one of the significant advantages of such systems is that you can do the installation yourself.

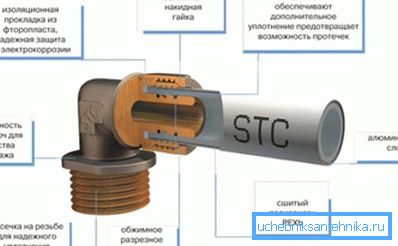

Installation can be done in two ways: using compression or pressure fittings.

Note! Compression-type fittings are considered simpler to install and can be used when installing pipelines for supplying not only cold water, but also hot water.

For the work you need these tools:

- Split ring.

- Spanners.

- Compression fitting.

- Crimp nut.

- Knife pruner.

Instructions for the work consists of these simple steps:

- We put on one end of the pipe crimp nut. It should be located on the connector side.

- Fix the split ring so that its edge is at a distance of a millimeter from the cut of the pipe. Check that the pipe is free to fit on the fitting fitting, until it stops.

- It is not necessary to remove the faceplate, just like performing any additional actions.

- Using wrenches, fasten crimp nut.

Tip! When tightening the nut, do not apply excessive force, as this may cause teething.

- Fix the pipes on the walls or floor of the house. You can do this through clips.

Note! When installing such a system, it is advisable to first consult with professionals, which will protect you from design errors that may adversely affect the operation of the installation.

Installation with press fittings

This method allows for a reliable connection of water pipes. However, in this case, the system is not removable, since installation in this way involves the use of a press tool.

In order to connect the PE pipes to the presser fittings, you will need:

- Expander of a specific diameter.

- Pressure fittings.

- Hydraulic press (suitable and manual).

- Clamping sleeve.

Installation is carried out as follows:

- We put on the pipe continuous clamping sleeve.

- We insert into it the dilator of the desired diameter until it stops.

- Carefully reduce the handle of the expander to the stop and hold it in this position for a few seconds. Products made of cross-linked polyethylene have such a property as molecular memory, due to which it will be almost impossible to remove a pipe from a fitting in a few minutes.

- For fitting the fitting using a hydraulic or manual press.

Installation of PE pipes to create water supply systems

For the installation of water pipes from PE pipe according to GOST 18599 2001 there are several ways:

| Butt welding | This method is suitable for high pressure pipelines. It is most reliable in particular for difficult places in contact with aggressive media. Welding products is possible only if they were made by one manufacturer. Pipes of different brands will not allow to obtain a high-quality seam, and as a result, deformation and ruptures may occur over time. |

| Assembly with threaded fittings | The easiest way to install water systems. For better tightness, specialists use teflon winding or any other compactor. To connect a plastic product to a metal, a combined fitting or transitional coupling is used. |

| Cold welding or adhesive method | Many consider this method unreliable, which is not true, since in some cases this connection experienced the pipeline itself. The ends of the pipes are coated with a special adhesive composition and inserted into the connecting sleeve. The edges are preferably treated with sandpaper before applying glue. |

Conclusion

Today, polyethylene products are widely used to create pipelines and heating systems, and the PE-to-gas pipe allows you to create reliable gas supply systems. Polyethylene has a lot of advantages over metal and gradually displaces it (see also the article Pipe AIV: technical characteristics, division into classes and groups).

One of the main advantages of such products is the ability to carry out installation without special skills and the use of specialized equipment.

For a more detailed introduction to this topic, you should definitely watch the video in this article.