Perforated tube: a quick guide to making

The main difference between the perforated pipeline and the usual one is that there are a number of round or square holes on its surface. Of course, using such pipes for a water or gas pipeline will not work, but perforation allows them to be used in a different quality. For example, a perforated stainless steel pipe can be efficiently incorporated into the drainage system.

Scope of the perforated pipeline

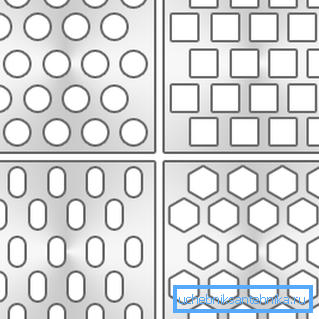

Perforated piping can be classified by perforation type (round, oval, square or rectangular). There is also figured perforation.

Most often such a pipeline is used:

- In drainage systems;

- As bearing structures. The perforated steel pipe weighs much less than with a solid wall;

Note! When using such a pipeline as a supporting structure, it is necessary to take into account some reduction in bearing capacity.

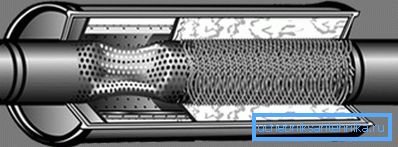

- In car silencers. The perforated tube is inserted into the casing from a tube with a solid wall and due to this, the sound is effectively suppressed;

- For the organization of ventilation.

In addition to the metal, corrugated plastic piping is widely used (mainly for drainage systems). Plastic greatly facilitates perforation.

How to make a perforated pipe?

In the factory, there will be no problems with this; automatic equipment guarantees fast and high-quality drilling. In addition, they will be placed perfectly exactly relative to each other.

But sometimes it becomes necessary to perform the perforation yourself, in which case the instruction will look like this:

- markup needed;

- the pipe is securely fixed (either in a vice, or, if dimensions do not allow, on the ground);

- holes are drilled (in this regard, specific recommendations depend on the type of material);

- at the final stage, the walls should be cleaned of metal chips, if necessary, the edges are processed with a file.

Steel pipe perforation

If you have the right amount of usual at hand, and you need a perforated metal pipe, you can simply drill holes in its walls and not spend money on buying a new pipeline. The main difficulty in this case consists in drilling holes in the walls. (See also the article Drainage pipes: features.)

If the tube is of small diameter, the locations of the holes can be applied to the sheet, and then simply glue them onto the metal and mark the position of the holes with a core. After drilling the sheet can be easily removed.

If the diameter and length of the pipeline is significant, then at the ends you can make marks at an equal distance, then stretch the string along the length of the pipeline segment, divided into equal segments, you can put marks on the metal.

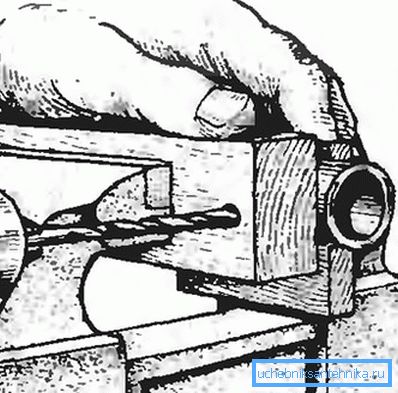

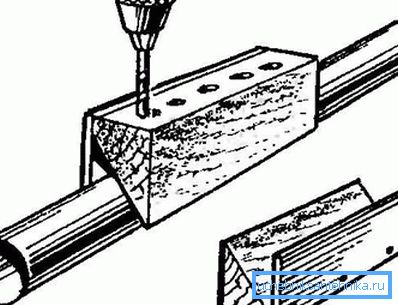

The main problem when drilling metal with your own hands is that the drill is difficult to hold in place, it simply slides off. For a pipe of small diameter, you can use an ordinary wooden bar, the width of which corresponds to the outer diameter of the pipe.

In the bar you need to make a hole that exactly matches the diameter of the drill. After that, the pipe and the bar is tightly fixed in a vice. The main difficulty is to ensure the exact location of the wooden bar, the hole in it must be accurate to the millimeter located above the mark on the metal, the price of such a device is minimal.

Perforation of a large-diameter pipe is possible using a simple wooden jig made from a triangular bar of dense wood and a metal plate or wooden shield. When used, the pipeline is simply pressed against a flat portion of the earth's surface.

As for the holes, in form, different from round (square, rectangular), they can also be made independently. True, this will have to work a file.

It is impossible to drill a square, and at home the punching operation is impossible, so a square hole can be obtained in the only way:

- a round hole is drilled, the diameter of which is only slightly smaller than the width of the square;

- do it by hand with your hands to grind off metal around the perimeter of the future hole.

Given the complexity of this method and not the highest quality of holes, it can hardly be recommended. Easier to drill a little more round holes.

Cast iron pipe perforation

In this case, the main subtleties lie in the correct selection of the drill and the observance of the drilling mode. Cast iron material is rather capricious and rather fragile, so you need an increased accuracy.

When drilling a cast iron pipeline, it is advisable to adhere to the following recommendations:

- if the diameter of the future hole is large enough, then it is better to drill it gradually, first small diameter, then the diameter of the drill gradually increases;

- you need to start drilling at low speed, and then you can add speed, but it is better not to hurry;

- Do not put much pressure on the instrument;

- The use of a drill with a tip will be optimal, and the angle should be about 118 ?. It is possible to choose a drill depending on the material on the basis of the data in the table.

Note! When drilling iron, not chips, but fine powder is formed, therefore protection of the visual organs and the respiratory system is obligatory.

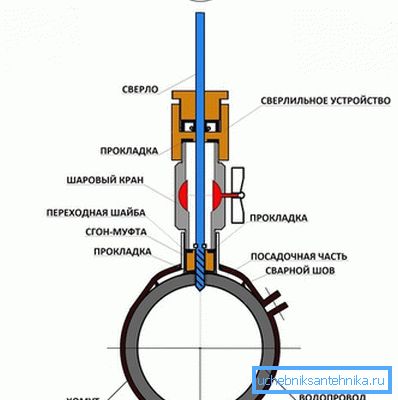

The ideal option not only for drilling iron, but also for steel can be considered a special device, which is simply fixed on the pipe and moved along it. This ensures that the holes are perfectly positioned relative to each other, and the perforated stainless pipe will be obtained very quickly. (See also the article Cast Iron Sewage Pipes: Features.)

Plastic pipe punching

Plastic does not create any problems when drilling, so there are no special limitations here. It is possible to advise unless it is more careful to approach the issue of pipe marking.

Due to the ductility of this material, perforation is often used instead of drilling. They can be staggered or opposite each other. Propyls are preferable because they have less effect on reducing strength, moreover they have a larger area.

Summarizing

Perforated pipe is an indispensable element in solving some problems, for example, organizing proper drainage. The technological process does not require high qualification, it is enough and minimal skills to work with a conventional drill. Due to this perforation can be done independently.

The video in this article shows one example of using a perforated pipe.