Pipe 09g2s: used raw materials, production technology,

What kind of steel is 09g2s? What is its composition? What is and by what standards is a pipe made from this steel - say, pipe 219-8 09g2s? What is the manufacturing technology of these products? Let's try to find the answers.

Steel 09g2s

This is the name of low-alloy structural steel for welded steel structures. The range of its working temperatures is from -70 to + 425С, which allows using the material, among other things, in the most severe climatic zones, as well as for transportation of high-temperature gases and liquids.

The total chemical composition is as follows:

| Element of the periodic table | Content% |

| C | 0.12 or less |

| Si | 0.5 - 0.8 |

| Mn | 1.3 - 1.8 |

| Ni | 0.3 and less |

| S | 0.04 and less |

| P | 0.035 and less |

| Cr | 0.3 and less |

| N | 0,008 and less |

| Cu | 0.3 and less |

| As | 0.08 and less |

| Fe | 96 - 97 |

Curiously: in the naming system adopted in the Russian Federation, the name of the steel grade indicates the amount of carbon in 0.09%, and not the maximum allowable 0.12. The remaining symbols denote manganese (up to 2%) and silicon (less than 1%).

What else can you say about this brand:

- It is stronger than most steel., the price of which is at about the same level (about 25,000 rubles per ton).

- High viscosity, associated with a small amount of carbon, persists even in severe frost.

- What is especially useful - during welding there is no hardening or overheating, affecting plastic properties. (See also the article Butt-Weld Pipe: Features.)

Pipes

What pipes made of steel 09g2s can be found on sale? Since we are dealing with an exceptionally strong metal, it is logical to assume that this quality will be in demand. And in fact: steel is in demand primarily in the production of seamless pipes.

The reasons are quite clear: the longitudinal electric weld will always be the weak point of the pipeline. And where special resistance to hydraulic pressure is needed, they are trying to get rid of it.

What are seamless pipes used for? It is clear that for the installation of home plumbing with their own hands their strength is somewhat redundant: the priority area of application is high-pressure pipelines of various purposes. Thus, the pipe 168x14 St 09g2s with a wall thickness of 14 millimeters is designed for a working pressure of over 11 MPa (100 atmospheres).

Production technology

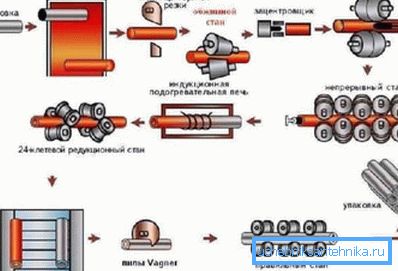

Modern industry produces seamless steel pipes in two main ways - hot and cold deformation. What does this mean in practical terms? We briefly describe the main stages of production.

Hot deformation

- A solid cylindrical billet (rod) is placed in a furnace, where it is heated to a temperature at which the steel becomes plastic.

- At the piercing mill, the pipe turns into a hollow cylinder - a sleeve.

- A mandrel coated with heat-resistant lubricants is inserted into the sleeve, forming its inner diameter.

- After reheating, the sleeve is rolled on the mandrel in successively reducing its diameter rolls.

- Calibrated and cooled billet after removing the mandrel is cut into pieces of the desired length, passes quality control and sent to the finished goods warehouse.

Cold deformation

The key difference of this technology is that, after the piercing mill, the liner cools and undergoes deformation with a temperature well below the point of recrystallization of the steel.

Important: after the rollers, the workpiece is tempering (heating followed by slow cooling). Thereby, the internal stresses accumulated during the deformation process are removed, which positively affects the ductility and the final strength of the products.

Profiling

A seamless profile tube - square or round - is obtained from the same round billet, again, by deformation in the rollers with preliminary heating or subsequent heat treatment.

Assortment

What sizes of pipes can be found on sale? The table of a range of hot-rolled pipes is contained in GOST 8732-78, cold-deformed - in GOST 9734-75. For the profile products there are their own standards: square product range can be found in GOST 8639-82, rectangular - in GOST 8645-68.

Hot rolled

According to GOST 8732-78 provides the following range of sizes:

- Diameter - from 20 to 530 mm.

Note: in coordination with the customer, products with a diameter of 550 mm can be made.

- Wall thickness - from 2.5 to 75 mm.

In addition to the list of sizes, the standard contains instructions for manufacturers on limit tolerances:

| Outer diameter, mm | Deviation limit | |

| Normal accuracy | Increased accuracy | |

| 50 or less | 0.5 mm | 0.5 mm |

| 50 to 219 | one % | 0.8% |

| Over 219 | 1.25% | one % |

Cold-formed

According to GOST 8734-75, cold-rolled pipes have a slightly different range of sizes.

- The minimum outer diameter is 5 mm, the maximum is 250.

- Wall thickness - from 0.3 to 24 mm.

Existing tolerances:

- For an outer diameter of up to 10 mm, a deviation of no more than 0.15 mm is permissible.

- For 10-30 - 0.30 mm.

- For 30-50 - 0.4 mm.

- With a cross section of over 50 mm, the deviation should not exceed 0.8% of the nominal.

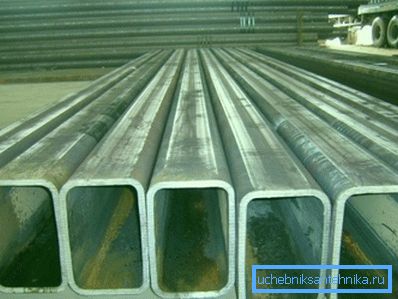

Rectangular

Sizes range from 15x10 to 180x150; In addition, the standard provides for special sizes - up to 230x100. Wall thickness - from 1 to 12 (for products of special sizes - up to 20) mm.

Square

Here the minimum size is 10 mm with a millimeter wall. Maximum - 180 with a wall thickness of 14 mm.

Conclusion

We hope that we were able to satisfy the reader’s curiosity in the field of acquaintance with rather exotic types of pipe products. As always, the video in this article will offer additional information. Successes!