Pipe 100x100x4: production, use, regulatory documents

What is the specific weight of a pipe 100 per 100 by 4 millimeters? How is it made and for what purpose is it used? Are there any regulatory documents regulating its production? Let's try to answer these questions.

Standard

To begin, find out what should be our pipe according to GOST.

And here we are immediately awaited by a surprise:

- In general, steel profile pipes should be manufactured according to the technical requirements set out in GOST 13663-86. The document contains a list of used production technologies and steel used in this case.

- GOST 8639-82 supplements the previous document: it contains a range of all square tubes without exception.

What is the surprise? And the fact that the second document for size 100x100 provides for versions with wall thicknesses of 6.0, 7.0, 8.0 and 9.0 millimeters.

A further search in the regulatory documentation leads us to an unexpected conclusion: a product with parameters 100x100x4 is not even a pipe at all, but (we quote) a steel bent closed square profile for building structures. And it regulates its manufacture (and technical conditions and range) a completely different document - GOST 30245-2003.

Useful: this standard applies not only to square, but also to rectangular profiles. The maximum sizes provided for them are 350x300 and 400x200.

Assortment

The assortment given in GOST contains, among other things, the specific weight of a square pipe 100x100x4. Actually, let us give a description of several popular standard sizes of profiles contained in the standard (see also the article Profile pipe 100x100: main characteristics and application features).

| Side mm | Wall thickness mm | Weight per meter, kg |

| 40 | 2.0 | 2.31 |

| 2.5 | 2.82 | |

| 3.0 | 3.30 | |

| 3.5 | 3.76 | |

| 4.0 | 4.2 | |

| 50 | 2.0 | 2.93 |

| 2.5 | 3.60 | |

| 3.0 | 4.25 | |

| 3.5 | 4.86 | |

| 4.0 | 5.45 | |

| 4.5 | 6.02 | |

| 5.0 | 6.56 | |

| 5.5 | 7.07 | |

| 6.0 | 7.56 | |

| 60 | 2.0 | 3.56 |

| 2.5 | 4.39 | |

| 3.0 | 5.19 | |

| 3.5 | 5.96 | |

| 4.0 | 6.71 | |

| 4.5 | 7.43 | |

| 5.0 | 8.13 | |

| 5.5 | 8.80 | |

| 6.0 | 9.45 | |

| 80 | 3.0 | 7.07 |

| 3.5 | 8.16 | |

| 4.0 | 9.22 | |

| 4.5 | 10.26 | |

| 5.0 | 11.27 | |

| 5.5 | 12.25 | |

| 6.0 | 13.24 | |

| 6.5 | 13.86 | |

| 7.0 | 14.72 | |

| 7.5 | 15.56 | |

| 8.0 | 16.36 | |

| 100 | 3.0 | 8.96 |

| 3.5 | 10.36 | |

| 4.0 | 11.73 | |

| 4.5 | 13.08 | |

| 5.0 | 14.41 | |

| 5.5 | 15.71 | |

| 6.0 | 16.98 | |

| 6.5 | 17.94 | |

| 7.0 | 19,12 | |

| 7.5 | 20.27 | |

| 8.0 | 21.39 |

Obviously, in order to use this table to calculate the weight of a pipe 100x100x4 of a certain length, it is necessary to multiply the mass of a meter by its molding. Say, 24 running meters will weigh 24 x 11.73 = 281.52 kg.

To recalculate a ton of steel per meter, you will have to do the reverse operation - divide 1000 kg by 11.73 kg / m; the result in this case will be 85.25 m.

Requirements

Let's find out what requirements GOST 30245-2003 imposes on products produced in accordance with it:

- The document contains requirements for the composition and quality of steel used in production. The complete list is quite large; among other things, the document indicates that the steel grade must be indicated on the delivery request.

- The curvature of the profile in both planes should not exceed 1 mm per linear meter.

- The twisting of the solid profile can not be more than 0.5 mm / linear meter +2 mm for the entire length.

- The convexity and concavity of the walls should not exceed 1% of the nominal size.

- The ends are cut at right angles.

- Permissible deviations from the nominal size are determined by its value.

| Size, mm | Tolerance |

| Up to 100 | +1%, -1%, but not more than 0.5 mm |

| Over 100 | +0.8%, -0.8% |

- Profiles are supplied with a length of 4 - 12 (in agreement with the customer - 4 - 13) meters. The length can be unmeasured, dimensional and multiple dimensional; in the latter two cases, a deviation of no more than +60 mm is permissible.

- Sunsets, cracks and deep risks on the surface are unacceptable. Minor defects (roughness, dents, etc.) are allowed, but only if they do not lead the product beyond the limits of maximum permissible deviations.

- From the point of view of production technology, all profiles corresponding to this GOST are electrowelded, and in accordance with the text of the document, the seams can be welded only by high-frequency currents. The seam should be located at a distance of at least 4t from the corner, where t is the wall thickness.

- After welding, the longitudinal seam is cleaned outside of the burr (rising above the plane of the solidified melt). The remaining burrs cannot rise above the surface by more than 0.5 mm with a wall up to 4 mm and 1 mm with a greater thickness.

- Finally, the key difference between profiles and pipes: since they are not used to transport liquids and gases, non-welded sections of the longitudinal seam are allowed. Their length should not exceed 50 mm per running meter, while the length of one undoped section cannot be more than 20 mm.

To clarify: it is permissible to correct defects with your own hands, using manual arc welding. The re-welded seam is cleaned from slag and deburring.

Production

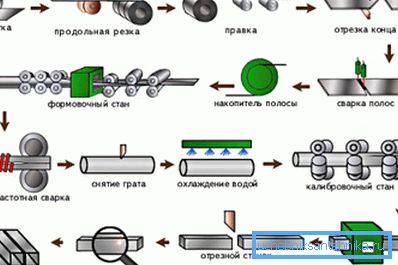

Again: all products manufactured according to GOST 30245-2003 are electrowelded, made from round billet welded by high-frequency currents by molding in rollers.

In short, the process looks like this:

- The raw material for production is strip - a steel strip delivered in rolls. It is rewound to coil with boiling transverse seams to ensure continuity of production.

- The next stage is the formation by rolls of a round billet. Passing several rolls with rolls, the strip is rolled into a tube - still open.

- Then the pipe is welded. High-frequency eddy currents heat the weld area to the melting point. This method of welding favorably differs from alternatives — arc in an argon environment and electron beam welding — at a high speed; this ensures low cost and, consequently, a reasonable retail price.

- Round billet passes rollers forming a square profile.

- The last stage is cutting the endless profile into segments of the required length, passing the control and moving the finished product to the warehouse.

Application

Instructions for choosing the scope of use of products directly follows from the description of the standard by which square profiles are produced. They are used in construction as constructive elements that must have considerable rigidity with a minimum weight.

Here you need to make a small lyrical digression and explain the difference between the key operational properties of circular and shaped pipes.

- Round profile provides maximum internal cross-section with minimum wall area. Obviously, it will be most beneficial for the transport of liquids and gases.

Practical consequence: the minimum area of the walls will provide the maximum tensile strength at their fixed thickness. That is why all the main oil and gas pipelines, the pressure in which amounts to hundreds of atmospheres - is round.

- Square and rectangular sections, on the other hand, provide maximum rigidity.

Due to what?

Let's make a small visual demonstration:

- Pick up a steel student's ruler.

- Place it on the edge of the table so that half of the ruler is on the outside of the tabletop.

- Fix the edge lying on the table, and press lightly on the free end of the ruler. She bent, is not it?

- Now put this line on the edge and repeat the experiment. The result is a bit predictable, right? By applying the greatest possible effort, you will not cause the slightest deformation.

If the bending force is oriented perpendicularly to either side of the pipe, its two walls will be in the role of such a ruler. Maximum stiffness with minimum weight, remember?

Hence the typical applications:

- Racks of canopies, wind-resistant barriers, bus stops.

- Bearing beams of prefabricated residential, industrial and administrative buildings.

- The slopes of the bearing metal, designed for a significant operating load.

Conclusion

We hope that the material offered to the attention of the reader will be useful.

If any questions remain unanswered - perhaps it will be in the attached video in this article. Successes in construction!