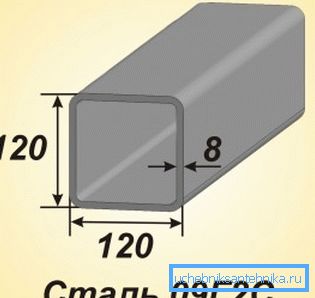

Pipe 120x120x8: features and scope

In modern construction there are a huge number of different materials that can be used in places where there are heavy loads. However, if we talk about the conformity of price and quality, then all the arguments and preferences are reduced to one product, which has the ease of installation - a profile pipe.

Scope and variations

First we need to say that almost all such products are used as supports and reinforcement. At the same time, the weight of the profile pipe 120x120x5 is quite large, although products with thicker walls have increased strength and can withstand increased loads.

That is why it is very important to properly balance the bearing properties and the pressure that can occur when using heavy elements.

Variety of wall thickness

First of all, it must be said that the material made of steel with a thickness of 8 mm is used quite rarely. This is due to the fact that even the weight of the 120x120x6 pipe is 21.48 kg, which is 6.65 kg less than this product.

The result is simply enormous loads on the base.

- Given this, such materials are often used in the manufacture of individual supports or racks.. For horizontal positioning it is better to use a channel or an I-beam.

- Special attention should be paid to products whose wall thickness is 5 mm. The fact is that the weight of 1 meter of pipe 120x120x5 is 18.05 kg, which is not so difficult for massive structures, and the strength of such a material is quite high.

- The most popular product in this area is considered to be a construction with walls of 4 mm.. Many experts believe that it optimally combines all the necessary qualities and does not create excessive loads. However, the weight of the pipe 120x120x4 is 12.06 kg, which means that in the manufacture of long spans, progress may form, which is eliminated with the help of props.

- There are several other varieties of such materials that differ in wall thickness.. This greatly facilitates the work of designers, because they can pick up a product of the desired strength, which will not weigh down the structure. At the same time, the price also depends on these parameters, which makes it possible to save money.

Tip! When working with this type of material, such a concept as durability for the future is simply inappropriate. It will only lead to a very large overrun and shorten the life of the structure, exerting an excessive effect on the base.

Application area

Considering that the weight of the profile pipe 120x120x4 can be considered relatively small, for products with similar dimensions, this material is actively used to create racks in tube frames of various structures. It is also used in the manufacture of some devices and even machines.

With products that have a greater thickness of the walls of the case, things are a little different. The fact is that even the weight of the pipe 120x120x5 for some types of structures can be considered redundant. Therefore, the main purpose of this material is to create supports and racks.

It should be noted that the products of this kind perfectly tolerate even very large end loads. This is evidenced by numerous objects, where heavy and massive roofs are located on only six or eight pillars of this material. (See also the article Hot-Rolled Pipe: Features.)

Tip! Such products can have a rather extensive scope, since even small pipe cuts can be used to make various parts or elements of a large system. Therefore, each expert determines the very need for one or another of its types.

Recommendations of the masters

- If the work is done by hand, it is necessary to follow all the instructions presented in the project. This particularly applies to the choice of materials and the location of the ribs.

- It should be noted that most manufacturers sell their products not in running meters, but per kilograms. Therefore, it is sometimes very important to know the weight of the selected type of material.

- It must be said that the instructions for the use of such products are usually written taking into account the fact that they are made of ordinary metal. Materials for which aluminum or stainless steel is used have completely different characteristics and need additional consideration.

- Such pipes usually have quite impressive dimensions and therefore, when purchasing them, it is very important to immediately resolve the delivery issue, since it can amount to a rather impressive amount.

Conclusion

Having studied in detail the video in this article, you can get more detailed information about this type of pipe and its application. Also, taking into account the text that is presented above, it should be concluded that it is very important to observe the strength-to-mass ratio in the manufacture of various structures. This will not only save, but also affect the life of the entire product.