Pipe 12x18h10t: characteristics and scope of stainless

This type includes hot- and cold-deformed seamless pipes made of steel with a slight inclusion of rare-earth metals, the brands of which by chemical composition correspond to GOST No. 5632/72. The list includes stainless steel pipe 12x18H10T, as well as the varieties listed below.

Technological requirements for the material

The operational and technical requirements are as follows.

- Corrosion Resistance.

- Long service life.

- Increased strength.

- Ability to restore the mortgaged properties after minor mechanical damage.

- Resistance to aggressive substances.

The above properties are achieved through modern technology, using unique alloys. As a result, the material does not lose its inherent qualities even after interaction with active chemicals.

A distinctive feature of the products is not only an affordable price and a large range. A wide range of applications allows the use of products not only in construction but also in the production of equipment for the medical industry.

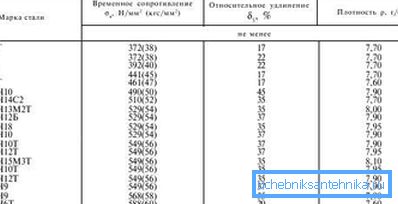

Steel grades for seamless products

The table below shows all categories of seamless pipes of the following stainless steel grades.

| Production method | Production method |

| Seamless | Seamless |

| hot deformation marks | cold forming |

| 08x13 | 12x18H10T |

| 08x17T | 08x17T |

| 12x13 | 12x13 |

| 15x25T | 08x13 |

| 15x28 | 12x17 |

| 04x18H10 | 15x25T |

| 10x23H18 | 04x18H10 |

| 08x17H15M3T | 08x20H14C2 |

| 08x18H10T | 10x17H13M2T |

| 08x18H10 | 08x18N12B |

| 08x18H12T | 08x18H10 |

| 08x18N12B | 10x23H18 |

| 08x20H14C2 | 08x18H10T |

| 10x17H13M2T | 08x18H12T |

| 12x18H9 | 08x17H15M3T |

| 12x18H12T | 12x18H12T |

| 17x18H9 | 12x18H9 |

| 08x22H6T | 08x22H6T |

| 17x18H9 | |

| 08xH28MDT |

Note! The instruction provides for the maximum (up to 0.02%) sulfur content in steel for elements subject to the welding process. Also, seamless counterparts are made with or without heat treatment.

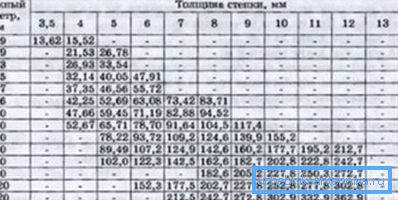

Dimensions of hot-rolled products

- Unmeasured length (from 1.5 m to 10 m).

- Measured length (in the framework of unmeasured, but with a maximum deviation of +15 mm in size).

- Multiple dimensional length. In the framework of dimensional, but with an allowance of 5 mm, with a maximum deviation in size of +15 mm. The minimum multiple size is 300 mm.

- Limited sizes. In the framework of dimensional, but with a maximum deviation of ± 500 mm.

State standards

- The standard for hot-rolled seamless pipe materials is GOST 9940/81. Non-corrosion-resistant metal is used for their manufacture.

- Pipes according to GOST 9941 81 include seamless pipe products from corrosion-resistant steel of cold-deformed and heat-deformed manufacturing methods.

- GOST 5632 72 applies to alloys and steel on nickel and iron-nickel bases. Materials are resistant to elevated temperatures and are not afraid of corrosion.

Sizes of cold formed pipes

- Unmeasured length The wall thickness is:

- Up to 0.5 mm (0.75–7 m).

- From 0.5 to 1 mm (1.0–7 m).

- From 1 mm and above (1.5–12.5 m).

- Measured size (in the framework of unmeasured products, with a maximum deviation in magnitude plus / minus 15 mm).

- Length, multiple of the dimensional (in the framework of the dimensional, but with an allowance of 5 mm for each cut). The maximum deviation in length is +15 mm, with a minimum of a multiple of 300 mm.

Note! These tubes are heat treated. Micro-additives of rare-earth metals are allowed.

Electric products

In this category are stainless analogues for use in the construction of structures and pipelines. This, as well as the categories listed above, can be used in the construction and installation works performed by yourself.

For the manufacture of this class of products is metal corresponding to State Standard 11068-81:

- 10x18H10T.

- 04x17T.

In the following grades GOST 5632-72 steel is used:

- 08x18T1.

- 08x18H10T.

- 08x18H10.

- 10x17H13M2T.

- 12x18H10T.

- 10x17H13M3T.

- 08x22H6T.

- 08x21H6M2T.

- 08x17H13M2T.

- 06N28MDT.

- 03x18H10T.

- 03x17H14M3.

According to the standards, materials from steel 08x18H10T, 04x17T, 12x18H10T, 10x18H10T are thermally processed.

Note! State standard 11068 81 applies to electrowelded products from stainless steels. The material is intended for the manufacture of structures for various purposes and pipelines.

Calculate the mass of the meter pipe

There is a formula by which it is easy to calculate the weight in kilograms of a meter of pipe.

M = psng (Dn-sn) / 1000, where:

- Dn is the outer nominal diameter;

- sn is the nominal thickness (in mm) of the walls;

- g is the density (g / cm2) of the metal, depending on the brand.

Below are the weight parameters.

- The mass of 1 m of the pipe 12x18H10T 426x8, 12x18H10T, 10x18H10T, 08x18H10T, 08x18H10, 03x18H10T, 08x21N6M2T is 7.9 kg.

- Products 10x17H13M3T, 10x17H13M2T, 03x17H113M2T, 03x17H14M3 - weigh 8.0 kg.

- Material 08x22H6T - 7.6 kg.

- Grades 04x17T and 08x18T1 - 7.72 kg.

- Mark 06N28MDT - 7.95 kg.

Conclusion

Innovative technologies allow you to create multifunctional materials. If earlier it was necessary to look for highly specialized materials for a particular case, then today the scope of their application has expanded considerably.

More information in the video in this article.