Pipe 160 to 160: detailed overview and scope

Profile pipes are very different from their "round counterparts". The rectangular, square or oval shape makes it impossible to use them as, for example, a plumbing or sewer pipeline, but opens up a host of other possibilities. In particular, the flat edges allow them to be used for the construction of frames for various structures.

Regulatory requirements for the profile tube

Even if the pipeline will be used for business purposes, and all the work will be done by hand, it will not be out of place to become familiar with the standards.

You can select several such documents at once related to characteristics, labeling rules, the process of production and storage of a square pipeline:

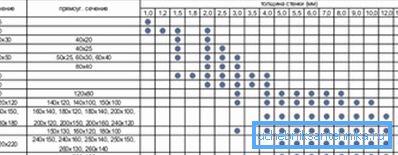

- GOST 8639-68 - the document shows the range per square pipeline, specifies the labeling rules and the basic requirements for the geometric dimensions;

- GOST 8639-82 - contains the same data with minor amendments;

- GOST 30245-2003 - the last regulatory document, which combined the data not only through a pipeline with a square, but also with a rectangular section. In addition, some new sizes appeared in the product mix, which were not in the documents of previous years. In addition to the geometric characteristics, the weight of the pipeline is also indicated in the product mix, for example, the weight of a shaped pipe 160x160x6 is 28.29 kg / meter. m

Requirements for geometric characteristics

Profile pipelines are often used as load-bearing structures, therefore the observance of the geometry of the section along the entire length plays a particularly important role.

Accordingly, the requirements are rather tough:

- the angle between the walls of the pipeline must be equal to 90 ?. The maximum error is 1.5 ?;

Note! If the cross section of the pipeline is very different from the square, it will be worse to resist the twisting deformation. This may affect the strength of the structure as a whole.

- the allowable curvature of the surface of the pipeline is 1 mm / 1m of length; on the basis of this limitation, the total allowable curvature over the entire length is calculated;

- permissible torsion is calculated using the formula 2 mm + 0.5 mm • L, where L is the length of the entire pipe;

- in addition, the perpendicularity of the cut is controlled. That is, the lengths on all faces should be the same (deviation in length is allowed up to +60 mm for pipelines of multiple and multiple lengths);

- wall thickness must match the sheet from which the pipe was created. This parameter strongly influences the weight, so the weight of the pipe 160x160x6 is 28.29 kg / bar. m, but with an increase in the thickness of only 1 mm, this figure increases already to 32.31 kg / bar. m

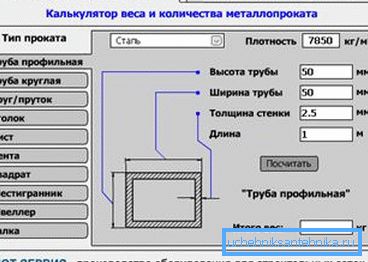

Note! More precisely, the weight of the pipeline can be determined using special online calculators. So you can take into account not only the geometry of the section, but also the material from which the pipe is made.

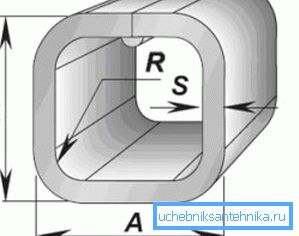

Special attention is paid to the radius of the rounding. The standard states that the radius of curvature should not exceed twice the thickness of the metal.

Of course, there is a certain tolerance in this question, the range of allowable values of the radii of curvature depends on the wall thickness:

- at a thickness of less than 6.0 mm, the value of the radius of curvature should be in the range from 1.6 to 2.4 metal thicknesses;

- at a thickness of 6.0 - 10.0 mm, the radius should not exceed 2.0 to 3.0 wall thickness;

- if the thickness exceeds 10 mm, then the radius value may be in the range of 2.4 - 3.6 metal thickness.

As for the height of the section, if it does not exceed 100 mm, the tolerance is ± 0.8%. If the profile size is over 100 mm, the error should not exceed ± 1% (minimum value ± 0.5 mm).

Technological requirements

In addition to the exact observance of the geometric dimensions, the profile pipe must meet several other criteria. Such indicators as the quality of the cut, the location of the weld and its strength are necessarily checked.

Note! With regard to the quality of the cut, then there is a view of the presence of burrs. So that the customer does not have to clean them with their own hands, they are removed even at the factory.

Particularly carefully controlled weld, because in theory this is the most dangerous place in the pipeline. In case of incomplete welding, non-compliance with the welding technology, the pipe may simply burst under load.

To avoid this, you must follow these rules:

- The weld should be located away from the pipeline fin. The minimum distance is 4 times the thickness of the metal;

- lack of penetration is allowed (i.e. places where the seam edges do not meet). Up to 50 mm of incomplete penetration is allowed per 1 m length, but the maximum length of one such section is limited to 20 mm;

- tensile strength of the seam should be 95% of the strength of the metal from which the pipe is made. The cost of the error may be too high;

- so that the weld does not interfere with the installation, a burr is removed from it (only outside). If the wall thickness does not exceed 4 mm, then the seam should not rise above the metal by more than 0.5 mm, with a thickness of more than 4 mm, the permissible elevation increases to 1.0 mm.

Also at the acceptance stage, a purely visual inspection of the metal surface is carried out. It is undesirable for the metal to have deep serifs, a thick layer of scale or rust. These phenomena are allowed, but they should not affect the thickness when cleaning the pipeline. More detailed instructions on quality control are in the standard itself.

The choice of material for the profile pipe

The starting material for a square pipe is sheet steel, this is the main requirement of GOST 30245-2003.

As for the material, the choice is between different steel grades, most often used:

- building steels;

- low alloy steels;

- carbon;

- general purpose.

The main criterion for the choice of material are the operating conditions of the pipe.

Examples of using a square pipe

Due to the high strength, the profile pipes made a worthy competition to the usual channels and I-beams. This is facilitated by the low weight of such a pipeline, since the weight of the profile pipe 160x160x5 is 23.83 kg / pog. m

Most often, the sectional steel is used as a frame for light structures, for example, hangars, greenhouses, pens for livestock, etc. Small sizes can be successfully used for the construction of elegant and durable sheds, canopies, fences on summer cottages.

Larger sizes are widely used in PGS. For example, a square tube with a large cross-section can act as a permanent formwork. As a result, time is saved on the construction of ordinary wooden formwork and the strength of the structure is increased.

Summarizing

Profile pipes - quite popular building material. Due to the high strength properties, they can be effectively used not only in private construction, but also in sand and gravel mix (see also the article Prub PE - material features and various mounting options).

The information in the article will help to make a general impression about the square pipes and determine the choice of size.

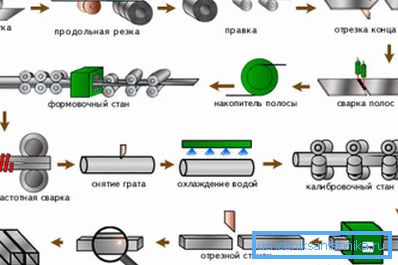

The video in this article shows the main stages of the production of a square pipeline.