Pipe 219 - everything you need to know about this type of

As you know, pipes are used almost everywhere, and the range and purpose of the application can be very diverse: from the device of highways to use as structural elements or protective elements. One of the most common product options is the pipe 219-8, this marking indicates the diameter of the element and the wall thickness (it can vary within very large limits).

Basic production options

There are several options for the classification of products, but the features of manufacturing have one of the largest values and have a huge impact on the performance characteristics of finished products. This is not surprising, because the fact that the weight of 1 meter of pipe 219x8 is much higher than, for example, the weight of pipe 219x5 is beyond doubt, but the wall thickness is not the only factor affecting strength.

Regarding production options, there are 4 main options:

| Welded elements | The most common option, the main advantages of which are low price and fairly good performance properties. Naturally, it is unlikely that it will be possible to carry out pipe laying work with your own hands due to the large mass of even small elements. |

| Seamless products | This option differs from the first in that the finished products do not have a seam, so their indicators of strength and resistance of both external and internal deformation are much higher. Of course, the cost of such seamless pipes is more, but the difference is not critical. The main production methods are forging or using high power special presses. |

| Hot-deformation seamless products | A special feature of this type is the production process, which looks as follows: a billet heated to a high temperature is supplied to the pipe-rolling machine, making the deformation much faster and easier, we can say that it is one of the most popular product variants, which is in great demand in various industries |

| Cold formed pipes | Without a doubt, this is the most durable type of product, manufactured by rolling through a cold billet machine. This technique provides the highest strength indicators of finished products, which is why this option is used on the most critical facilities and pipelines with high pressure. |

Important Product Features

Consider what the product type in question is used for and what important factors should be considered when choosing one or another option.

Note! All products must comply with the standards of GOST, there are quite a few regulations, as there are at least a dozen of pipe-making methods. But whichever option you choose, it is important that its quality matches the characteristics of the application in a given situation.

Main areas of use

Most often pipes of the considered diameter are used for the following purposes:

- Construction industry, it often uses only options with sufficiently thin walls, this is due to the fact that frames of various structures are erected from pipes or they are used as supports. They are very reliable and resistant to deformation, while the weight of the pipe 219-6 is very small.

- The considered product group is used even in the aircraft industry., most often as a highway for laying various communications and reliable protection from damage and destruction.

- Engineering widely uses pipes with the most various thickness of walls. At the same time, the scope of their application is enormous: from the manufacture of elements in spacecraft and special equipment to use as blanks in the manufacture of various components and elements.

- And of course, the most widely considered elements are in the housing and utilities sector., A lot of pipelines through which various substances pass are made from such a pipe.

Anti-corrosion protection options

As you know, steel is very susceptible to corrosion, and given the fact that pipelines lie in the ground, the question of protecting the material from negative influences is very acute.

That is why there are a lot of variants of protective coatings, all of them can be divided into several main groups:

- Cement-sand insulation (CPI), this method of protection is intended for use on the inner surfaces of pipes. The advantages include the cheapness of materials - cement and sand and high reliability of coatings that prevent the contact of metal surfaces with moisture and accordingly prevent the ingress of corrosion products into the water. Application technology provides high layer strength.

Tip! It will not be possible to apply such a coating without the appropriate equipment, so professionals should be involved in this type of work. It is worth noting that such a coating can be made on both new and used pipes.

- MAS (very enhanced isolation) - this option is different from the usual, so consider it in more detail. It is used for external protection of pipes and most often is a multi-layered structure that reliably covers the surface and prevents the ingress of moisture. At the same time, the materials used are quite light, for example, the weight of 1 meter of pipe 219x6 when using VUS insulation increases by no more than 10-15%.

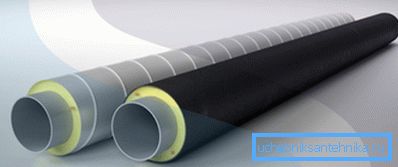

- Insulation with polyurethane foam can not only protect communications from adverse external factors, but also serves as an excellent insulation. To achieve the best effect, it is important to choose the correct thickness of the insulator. It is also very important that the top is covered with a layer of tin or sheet tape coating, this will prevent damage to the polyurethane foam and ensure the maximum service life of the products.

- Penopolimermineralny isolation not only perfectly protects the metal from corrosion, but also has the highest thermal insulation characteristics. That is why this option has become the widest distribution in the housing and utilities sector when laying heating utilities. The composition includes both polymer components and mineral: for example, sand, thanks to this composition, the coating is very reliable and durable.

It is very important to choose a coating in accordance with the characteristics of a particular system. Norms of SNiP prescribe the best options for certain types of work, but sometimes the decision must be taken independently.

Another important factor is the thickness of the walls, the principle “the more, the better” is not always suitable, as the weight of the pipe 219x10 and 219x50 differ many times, and the structures do not always allow the use of heavy elements. In addition, the thicker the walls, the smaller the conditional passage of the pipe.

Conclusion

Pipe 219 has been used very widely for several decades now, and in the near future the demand for it is unlikely to decrease. The video in this article will tell some features of the product group in question and clearly show some important nuances.