Pipe 40x40: how to choose billets for a strong metal

One of the varieties of shaped pipes is a 40x40 square tube. Depending on the purpose and scope of application, these products have different technical characteristics, in particular, thickness and weight. The instructions given in the article will help novice craftsmen who want to make this metal construction with their own hands, to select the model they need from the entire available range.

Specifications

general description

Pipe 40-40: 2 mm and greater thickness, unlike the round varieties of these products, is not used for arranging water pipes, heating systems and similar engineering networks.

The main sphere of its use is the installation of metal structures, as well as the use as the main supporting element in the construction of various buildings.

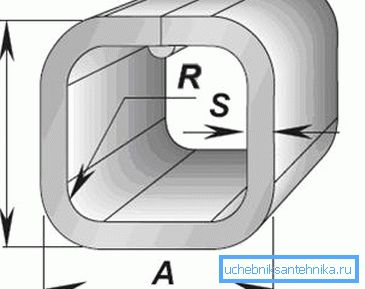

The shaped product has the following design features that distinguish it from round pipes and full-rolled metal:

- internal empty space;

- stiffening rib.

Thanks to this, the 40-40 4 and 5 mm thick pipe has the following indisputable advantages:

- High bending resistance.

- Good resistant.

- Low weight (for example, the weight of 1 meter of a 40x40x2 pipe is several times less than the weight of a full-bodied piece of similar size).

Due to the qualities listed above, it is possible to significantly reduce the metal consumption of structures without reducing strength. This makes it possible to build more complex and higher buildings on a less massive foundation.

Note! Due to the fact that a smaller amount of the initial material is used for the manufacture of the profile pipe, the price of the finished product is also lower than similar full-bodied parts.

As raw materials are usually used steel of various grades, which differs in terms of strength.

Pipe 40-40 3-5 millimeter thickness is manufactured by the following technologies:

- by rolling hot billets through a rolling mill;

- by stamping sheet steel and the subsequent welding of a longitudinal seam.

Weight parameters

In order to correctly calculate the strength and other necessary engineering parameters of the future metal construction, it is necessary to know exactly the mass of its individual elements.

After all, a weight of 1 meter of a 40x40x3 mm pipe may differ significantly from a similar parameter in a product with a thicker or thinner wall, which will require changes in the architectural project being prepared.

For example:

- product weight 40x40x1 - 1.21 kg (one running meter);

- pipe weight 40x40x2 - 2.33 kg;

- pipe weight 40x40x3 - 3.36 kg;

- pipe weight 40x40x4 - 4.3 kg;

- the mass of the part 40x40x5 - 5.16 kg;

- the weight of a part is 40x40x6 - 5.92 kg.

Note! The length of the products is not regulated by any building codes and depends on the manufacturer. Most manufacturers offer a service for cutting profile pipes into sections of the desired length, which facilitates their transportation, storage and installation.

State standards and specifications

Characteristics and consumer properties of profile pipes are clearly regulated by state standards and technical specifications, fixed by the relevant documents, which all manufacturers must comply with.

For example, the weight of a 40-40-2 pipe manufactured by the Severstal Production Association and the weight of a product manufactured by the Samara Metallurgical Plant should not differ.

This allows the end user to combine these or other products in one metal structure without additional control and verification of the characteristics of each of them.

You can learn these or other parameters by studying the following guidelines:

- TU 14-2P-328-97 - for steel bent shaped pipes with electric welded seam;

- TU 14-157-95-2007 - for galvanized steel tubes of square and rectangular cross-section, manufactured using electric welding;

- TU 14-105-737-2004 - for shaped electric-welded pipes made of carbon or low-alloyed steel, which are used in various industries and furniture production.

Differences between pipes according to GOST and TU

The standard profile square tube section of 40x40 mm, regardless of wall thickness, is made of ordinary steel. Only methods of so-called deoxidation differ.

Stand out:

- semi-calm steel;

- calm steel;

- boiling steel.

These parameters of raw materials are governed by GOST 380 and 1050.

The main spheres of application of the pipe corresponding to the State Standards:

- production of metal structures of varying complexity;

- making frames for upholstered and other types of furniture;

- in other branches of mechanical engineering and heavy industry.

In contrast to the above products, the profiled pipe, produced according to specifications, is about 10% heavier. Wall thickness is from 5 to 8 mm. Most often, these are measured products (12 meters long), however, as in the previous case, they are allowed to be cut in the production process into segments of the required length. The main difference is lower cost.

This type of detail is most often used for:

- furniture manufacturing;

- production of various decorative elements used for interior decoration of premises;

- in agriculture and some industries.

Independent manufacture of metal structures

The advantages of metal frames in the construction

Metal frames made from 40-40 mm steel profiled pipe have many advantages:

- Low price. As is known, the cost of a particular construction depends largely on the materials used and the construction technologies used. The estimate for the construction of the house on the frame technology will be several times less than the same calculation for the building being built in the classical way.

Note! A wooden frame dwelling will be even cheaper, but in this case strength and durability will suffer.

- High installation speed. Using a profile pipe, it is possible to almost halve the period during which a house will be built.

- During the construction of a building or structure using frame technology with the use of a profile pipe, there is no need to carry out “wet” construction processes (with the exception of laying the foundation). This reduces labor intensity and reduces installation time.

- The frame house made of a profile pipe does not shrink at all. Therefore, you can begin to decorate it immediately after the completion of the construction of the “box”.

Stages and features of work

The whole process of installing metal frames from square pipes can be reduced to three main operations:

- The length of the required length is measured from the metal pipe and cut off. To do this, you can use a gas cutter or grinder (depending on the wall thickness of the purchased parts).

- If necessary, bending pipes. This is necessary to give them the necessary radius. The tool here is a manual or automatic pipe bender for bending pipes. You can contact the plumbing from the housing department or in a special workshop where you are bent on special equipment without violating the integrity of their internal structure.

- The resulting parts must be welded into a single structure. Make sure that the finished product clearly corresponds to the previous drawing.

Conclusion

Square shaped pipes are an excellent material for construction, with many advantages. However, in order for the finished product to be strong and durable, you need to choose the cross section and wall thickness, as well as to calculate the strength, taking into account the weight of the pipes. Otherwise, the possible destruction of the structure.

For more information about the construction of buildings on the frame technology using profiled metal structures can be found in the video in this article.