Pipe 60 to 60 square profile: technical parameters and

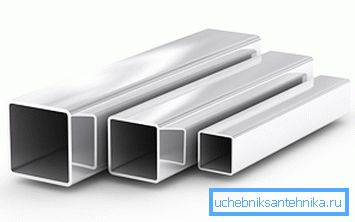

The range of specialized products can be quite wide, in particular, this includes a triangle, a rhombus, truncated circles and much more, but the most common profiles are squares and rectangles. The square tube 60x60, is only a special case of a profile product, it is a closed loop with dimensions of sides of 60 mm.

Important: if you calculate the percentage by area of use, the square pipe 60 60 is most in demand in the construction industry, it accounts for about 70%. Mechanical engineering takes the lion's share of the remaining thirty percent, and only a small part is accounted for by other industries.

What are the advantages of the form

- The square itself has two natural parallel stiffeners, in view of which the design is distinguished by enviable stability. Strange as it may sound, one-piece monolithic square-shaped steel has much lower stability characteristics. Plus, the monolith, naturally, will weigh immeasurably more than a 60x60x5 pipe.

- If you do not take into account stainless or alloyed steel grades, then all other structures with this form, without fail, are treated with special compounds that protect against corrosion.

- The square shape of the structures greatly facilitates the installation of such products on parallel-perpendicular bases. In addition, the subsequent lining, for example, drywall, is not particularly difficult.

- As is known, the construction itself, for example, a pipe 60 60 3 or a pipe 60 60 2 is hollow. In construction and mechanical engineering, this provides an excellent opportunity for laying various kinds of hidden wiring or communications inside the product.

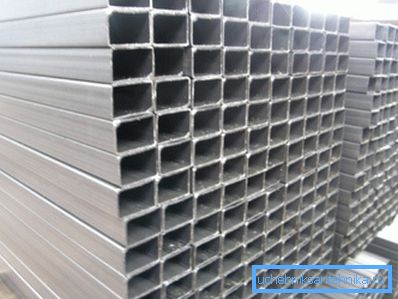

- Also, an important advantage is that the square shape is easily stored and packed in compact, regular piles.. This greatly simplifies the storage and transportation of goods.

Characteristics and secrets of manufacturing

Actually, if we talk about the characteristics of the structures of this form, then some of them are already incorporated in the marking. The first two digits describe the dimension of the sides in millimeters, the last value indicates the thickness of the walls.

But besides this, the price of the goods directly depends on the mass. Base release by weight, plus when calculating the load on the base, it is important to know what, for example, the weight of 1 meter pipe 60x60x4.

Weight data

In all reference materials, it is customary to contribute the calculated mass of the product with a length of 1 meter, in other words, the weight of 1 running meter. This value directly depends on two main characteristics, the main of which is the thickness of the wall of the structure, which is indicated in the marking by the last digit.

The second value is taken exclusively from the tables and describes the density of the metal from which the product is made. Suppose the average steel density is calculated on the basis of 7850 kg / m ?.

You can do these calculations with your own hands, but the value will be approximate. For calculations, you will need to scan the cross section of the structure and then calculate how the weight of the metal sheet. The square of the sheet is multiplied by the table value of the density and the thickness of the material.

Important: any batch of goods, except the certificate of quality, must have a passport. The instruction requires that in each document for the goods, it is mandatory to specify the weight of a running meter of this particular material.

If you are only going to buy and you need to know how much a 60x60 square tube weighs, then these data can be found in the relevant tables. The standard is taken by a range of square pipes of a certain size indicated in the corresponding GOST.

The thickness of the walls of products with a cross-section of 60x60 can vary between 1 - 8 mm. It is not realistic to list all the data in the article; for example, we give only the weight of several common sizes.

| Product Marking | Weight | Steel marking | In 1 ton |

| Pipe weight 60x60x2, 1p / m. | 3.71 lbs. | 1 - 3 PS. | 269m |

| Pipe weight 60x60x3, 1p / m. | 5.39 kg. | 3 SP - PS | 185m |

| Pipe weight 60x60x4, 1p / m. | 6.91 kg. | 3 SP - PS | 144m |

As you have noticed, in this table we have indicated the weight for a particular steel grade, this is quite important, since the weight of a pipe is 60 60 3, for a stainless steel or non-ferrous metals, it will already be significantly different. Data on how many meters are in 1 ton are also not given randomly. The fact is that the metal base and other trade organizations sell goods by weight, having these data makes it easier to calculate how many kilograms of goods you need.

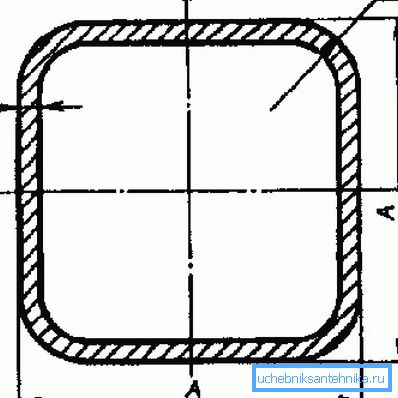

It should also be noted that a square cross-section is not always clearly square, therefore, in different GOST, structures with the same wall thickness and rib sizes can have different weights. This is because the corners can be sharp or rounded. For a product with rounded corners, the radius is often also indicated in the marking.

Important: Be careful, in the material mix according to GOST, a reference mass value is indicated for a given steel grade and specific section. In the same documents the possible value of the deviation is always indicated, as a rule, this value fluctuates within 10 - 12%.

Of course, the most modern and fastest method of calculation is now an online calculator. Such programs are designed so that they can be used even by a person far from the intricacies of the Internet.

There you just need to enter the initial data and in a moment you will be given an exact result indicating the errors and tolerances.

A few words about the production

Square tube 60 60, can be made in different ways. The choice of production method depends on the composition and grade of metal used. Also of great importance is what final characteristics are required to obtain.

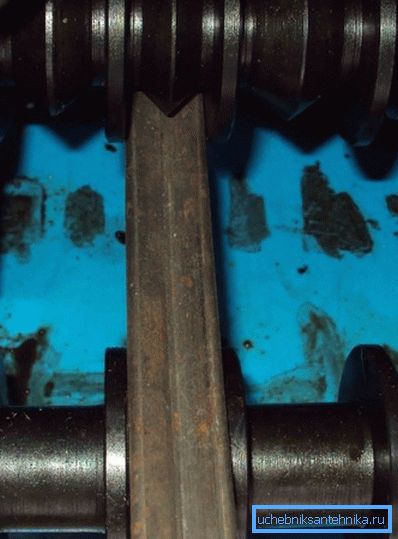

Production is divided into two major areas, the manufacture of solid-rolled products and curved welded structures. Each of these areas, in turn, is divided into several niches.

Solid products are made using two different technologies. This is hot rolling technology and cold drawn production. Both directions give out high-quality goods.

But hot rolling is designed more for the production of thick-walled structures of medium and large diameter. Cold-drawn pipes are distinguished by a thin wall and, accordingly, not a high mass.

Hot rolling has been known for quite some time. The process is expensive and energy-intensive. Initially, in special gas or induction furnaces, an already formed metal billet is heated to a temperature of more than 1200? C.

After which, in several stages, it is molded by repeated rolling. The internal cavity is made by a special device called a mandrel.

In the end, the resulting profile slowly cools down and then goes to pre-sale preparation, minor design defects are removed there. Before the release, the goods pass through the Quality Control Department, where all the documents are filled.

Seamless pipes are produced by special technology by pulling, forming a single sheet metal. With a cold reduction of metal, its internal structure changes, and it loses its elasticity. To restore elasticity, after molding, the metal is heated and allowed to cool slowly, this procedure is called tempering.

As for welded structures, they can be welded by electric welding or in induction furnaces. Pre-frame pipe is bent on special lines. This production is less expensive, the price of welded structures is much lower than that of solid-rolled, so they are much more widely used in industry.

The video in this article shows the subtleties of technology.

Conclusion

This profile is widely used in all areas of industry. Do not forget that any products of this class must be certified. If in ferrous metal products a certificate can be issued for a batch, then in the case of non-ferrous metals and alloyed steel grades each product must have a certificate (see also the article Shaped pipe 60 for 60: reveal all the features).