Pipe 60x40 mm - features and weight

Pipe section 60x40 mm is a popular structural material, which is used in the manufacture of various metal structures. This is due to its strength and many other qualities. Below we will look at the main features and characteristics of this product, as well as consider how to calculate the weight of a pipe 60 - 40 mm, which is one of its most important parameters.

General information

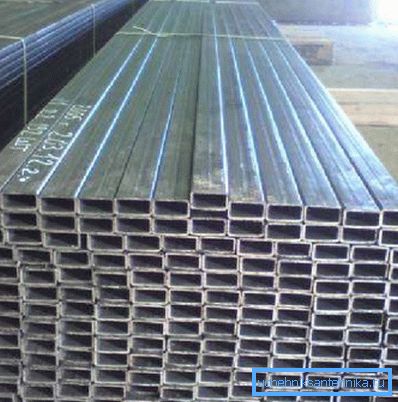

So, the profile pipe 60 - 40 mm is an empty rod-shaped pipe with a rectangular cross section.

The product can be made of the following materials:

- Carbon steel;

- Of stainless steel;

- Low alloy steel.

The production of these products, as a rule, is based on the deformation of a conventional round pipe, as a result of which it acquires a rectangular shape. In addition, there is another technology, according to which the metal billet (strip) is subjected to deformation in a calibration mill, after which welding is performed.

Special features

Properties

Compared with the product of circular cross section, the main feature of this material is high bending, fracture and twisting strength.

This can significantly reduce the weight of the metal, because the weight of pipes made of steel 60x40x2 will be significantly lower than the mass of a solid metal rod with equal strength.

According to data from the reference literature, the profile tube provides material savings of 25 percent compared with a round section product.

In addition, there are a number of other positive aspects, among which there are such as:

- Convenience and ease of installation, since the walls of the product are flat;

- Ease of loading and transportation thanks to a convenient form;

- Resistance to significant static loads;

- Resistance to temperature changes;

- Resistance to deformation;

- Affordable price;

- Convenience laying on flat surfaces.

It should be noted that many other properties of products depend on the method of their manufacture, and the material from which they are made. For example, stainless and galvanized pipes have good corrosion resistance.

Rolled products, as a rule, have thicker walls, with the result that it has greater strength. However, it should be borne in mind that the weight of the profile tube 60x40x2 of rolling type will be significantly higher than the mass of the similar welded product.

Note! The technical requirements for professional pipes made of carbon steel are governed by GOST 13662-86, which applies to cold and hot-deformed, cold-deformed electric-welded, as well as electric-welded profile pipes.

Specifications

Plastic pipe sections of 30x40 mm, as in fact, and any other sizes, are characterized by two types of parameters:

| Specifications | These include the following parameters:

They are regulated by state standards and specifications. |

| Geometric specifications | These parameters include:

Wall thickness and cross-section dimensions are always indicated in millimeters, and length - in meters. |

All characteristics are of great importance in the calculation of structures. For example, there is a pipe 60x40x2 - the weight of the product depends on the wall thickness. Knowing this parameter, it is possible to calculate the mass of the future structure.

Note! Metal base, as a rule, indicate the price for the weight of professional products, and not running meters, since the raw material components prevail in the cost of the material. True, we are talking about the theoretical weight specified in GOST.

Weight calculation

Since the assortment of the products in question is very extensive, certain difficulties may arise if, for example, it is necessary to calculate the weight of 1 m of a 60x40x3 pipe. Of course, you can learn this parameter from the metal-roll table, however, reference and technical literature is not always at hand.

Therefore, below we consider how to independently calculate this value. So, the mass of a meter of any professional pipe, as is known, depends on the cross-sectional area, i.e. on wall thickness. For example, you need to know the weight of the profile pipe 60x40x3 with a wall thickness of 4 mm.

You can perform the calculation using the formula for calculating the mass of sheet metal. The only difference is that it is necessary to calculate the perimeter of the rectangle in meters. The value obtained should be multiplied by the specific weight of steel, which is 7.85 g / dm3, and also by the wall thickness in millimeters.

As a result, the formula is as follows - M.P. = Sx2x (A + B) x ?, where:

- S is the profile wall thickness in meters.

- A and B are the lengths of the profile sides in meters (in our case, A = 0.06; B = 0.04).

- ? - 7850 kg / m3 (steel density).

Accordingly, the instruction for calculating the mass will be as follows:

- MP = 0.004x2x (0.06 + 0.04) h7850 = 6.28 kg.

- Since we need to know the weight of the three-meter product, the resulting value should be multiplied by three, thus, the weight of the pipe 60x40x3 is 18.84 kg.

As mentioned above, many of the metal bases put the price for the weight of the product, not the length. In this case, you may need to know the amount of the pipe, knowing the weight. For example, the total weight of the product is 157 kg, the wall thickness is 5 mm, and the length is 4 m.

In this case, do the following calculation with your own hands:

- First of all, you need to know the mass of one running meter of the product - MP = 0.005x2x (0.06 + 0.04) х7850 = 7.85 kg.

- After that you can find out the weight of the pipe is 60x40x4 - 7.85x4 = 31.4 kg.

- Now it remains only to find out the number of professional pipes, which is done by a simple mathematical calculation - 157 / 31.4 = 5 pieces.

Note! The real weight of the pipework will differ slightly from the data obtained by calculating by the given geometric formula. This is due to the fact that the real shape of products differs from the shape of elementary geometric shapes.

Here, perhaps, are all the main features of a 60x40 mm shaped tube.

Conclusion

Profile pipes, including the 60x40 mm section, have a number of unique qualities, thanks to which they have found application in a wide variety of applications. Most of the characteristics of these products are spelled out in the appropriate State Standards, however, in some cases it may be necessary to perform a mass calculation on their own.

As we found out, it is completely easy to do this with a simple mathematical formula.

From the video in this article, you can get some additional information on this topic.