Pipe adhesives: installation and necessary equipment

Recently, just a huge amount of various materials for the manufacture of plumbing systems. However, the most common of these are products that are connected by melting and then joining the two elements. That is why beginners often ask the question of how to spike polypropylene pipes with their own hands.

Equipment and its selection

To begin with, it must be said that there are so many different models of devices for doing this kind of work. They differ in shape, design features and additional functions. Therefore, it is necessary to approach the choice of a soldering iron very thoroughly.

Principle of operation and design

First of all, the apparatus for soldering polypropylene pipes consists of a heating element of a large area.

In this case, it is powered from the network through a kind of regulator in the form of a rheostat, which controls the voltage, and hence the level of heating.

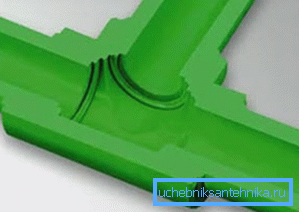

- Special nozzles are installed on the heating element that correspond to the inner diameter of the sewer fittings and the outer diameter of the pipes. Heat is transferred to them and when a certain temperature is reached, you can start working.

- It is worth noting that all such nozzles are made of metal with good thermal conductivity in order to minimize losses. At the same time, a special coating is applied over them, which does not allow the product to burn or stick to the nozzle.

Tip! It is necessary to immediately install two soldering devices with the diameters of the joints to be used. Therefore, some masters prefer to purchase such types of structures that allow the use of at least four different attachments.

How to choose

First of all, it is necessary to mention that the price of such a soldering iron is quite high, and it is very wasteful to purchase it for the work of disposable works. Given this, professionals recommend renting such tools.

- If the soldering iron is chosen for permanent use, then first pay attention to the quality of manufacture of the heating element. At the same time, experts evaluate the material of manufacture, power and functionality.

- For beginners or a simple man in the street should pay attention to the warranty and the number of holes for installation of nozzles.

- It is the soldering elements that are given increased attention. The fact is that the quality of the attachments will depend on the entire installation and the life of the product. Professionals usually immediately acquire a separate set of such high-quality products that they will use after the standard nozzles become unusable.

Tip! Experts recommend to pay attention to the popular and famous brands that have their service centers in the city.

Installation

When purchasing a tool for soldering polypropylene pipes, you need to immediately buy additional equipment. Usually, some manufacturers of soldering irons immediately complete their products with a mounting knife and a special cutter for cutting pipes. However, the quality of such tools leaves much to be desired, and specialists purchase them separately.

Project and cutting

Before you begin to work you need to prepare a project in advance.

It is necessary to display all the places of connections, transitions and points of installation.

- Some experts immediately prefer to put on a similar plan the size of the pipes to be used. However, in practice, the length of the segments may slightly differ from the value specified in the draft. That is why professional craftsmen do not recommend cutting all parts at once.

- If the installation is done at home, the manufacturing instructions advise you to make one span without soldering and, on its basis, start assembling the entire system for cold. So you can properly cut all the pipes without worrying about errors. (See also the article Plastic sewers: features.)

Tip! Soldering is best done in stages, detaching one element at a time, without disassembling the entire system. So you can avoid confusion during installation.

Work with a soldering iron

It is very important to say that the spikes on the pipes are created at different temperatures of the soldering iron or its power. It depends on the environment, the quality of the tool, the material used to make the nozzles and the fittings themselves. In this case, the maximum and minimum value on the scale of the instrument will necessarily lead to a negative result, no matter what the installers, who work with violation of technology, claim.

Given the similar characteristics of such materials, the temperature of adhesion of polypropylene pipes is chosen empirically. To do this, when buying everything you need, you should purchase an additional fitting. It, together with a small trim of the pipe, will serve as an element that is used for practice, allowing you to choose the right mode of operation.

After the temperature and heating time is selected, you can proceed to the main work. To do this, both elements need to be installed on the nozzles and withstand the time necessary for melting. Then these parts are interconnected and kept in this state until completely cooled.

It must be said that the soldering of polypropylene pipes is considered to be a fairly safe operation. But do not forget that you have to work with hot tools and materials, which means you need to use gloves to prevent burns.

Tip! Before you start soldering, you need to thoroughly wipe the materials from dust or dirt. Some professional craftsmen recommend using alcohol and rags for these purposes.

Recommendations of specialists

- Soldering tips must be handled very carefully.. Otherwise, it is possible to damage the protective and non-stick coating, which will immediately cause problems during installation or make it impossible.

- Each type of pipe requires its own approach when choosing the temperature and time regime for work. Even if the material is constantly used by one manufacturer.

- After installing the entire system, it is recommended to refrain from applying pressure to it for several hours.. During this time, must establish strong molecular bonds that are stronger than a solid product.

Conclusion

After reading the video in this article, you can get additional information about this operation and the tools necessary for its execution. Also taking into account the article above, it should be concluded that the process of pipe soldering is quite simple and does not require the presence of certain skills or special education.