Pipe bender for pipe itself

One of the most demanded materials, when carrying out construction works of the most different type, are metal pipes. In particular, we are talking about rectangular shaped tubes. In the household, they are used to make various designs from arbors, to sheds and extensions. And everyone who has dealt with them knows that quite often it is necessary to bend these pipes.

The problem can be solved in several ways, one of the most effective among which is the use of a pipe bender. This special tool can be found in the construction market without problems. However, it should be said that the price of such devices is often quite high.

Tip! If we are not talking about professional activity, then in order to save it would be much more expedient to make a pipe bender for the pipe with your own hands.

Scope of application

For the most complete understanding of the issue, it is necessary to say a few words about where exactly the benders are used. As mentioned above, the main application of these devices is construction, where bending the pipe is often a necessary action. The main problem is that without special adaptation this process is extremely difficult to implement. It is almost impossible to bend a profile without a wall crease, and any other pipe can be. But, if you use a pipe bender, you can achieve a uniform bending of the pipe at an angle of up to 180 degrees without any subsequent problems.

What are benders?

As for what types of pipe benders can be found, here it is necessary to say that there are quite a few varieties of this special device and they will be different in a number of ways.

- First of all, we are talking about the fact that you can find professional models and options for, so to speak, economic use. They will differ not only in their dimensions, but also in their working principle. This means that professional models are usually driven by an electric motor and hydraulics are used during operation, but household pipe bending machines will most likely be mechanical and work due to the muscular strength of the person. As it is easy to guess, the manual pipe bender will be much smaller and cheaper than its professional counterpart.

- In addition to the aforementioned differences, it can be mentioned that pipe benders differ in the diameter of pipes they can work with.

- The models also differ in the way of folding. So it is possible to distinguish pipe benders of arbaletny, spring and segment type.

Principle of operation

Before proceeding to the process of assembling an instrument such as a manual pipe bender, we need to say a few words about what the principle of its operation is based on. But the point is that the pipe placed in the machine bends either around a rounded template having a given surface radius, or the bending occurs as a result of uniform mechanical pressure on its surface from one side. It is preferable in most cases, as it is easier to manufacture will be the second option. That he will be discussed below.

Manufacturing

In order to make a high-quality machine for tube bending, work should be carried out in stages.

Training

As in most cases, if you need high-quality work, they should begin with careful preparation. And we are talking here not only about the need to prepare the materials that will be needed, but it is worth taking care that all the necessary tools are available.

Materials and tools

- Metal corner. It will be made from the machine frame itself. Although you can use a different material, like the same shaped tubes.

- You will need three rotating shaft bearings. You can search for ready-made, but you can make them yourself.

- You will not be able to do without fasteners like various bolts and rods.

- Bulgarian with cutting discs for metal.

- Welding machine.

- Measuring devices (roulette, angle, level, etc.).

- Work tool (set of keys, screwdrivers, hammer, etc.).

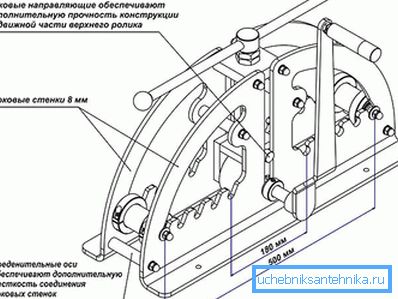

In addition, it is necessary to make independently or borrow from special literature the drawings of the future fixture. Thus, it will be possible at the preparatory stage to determine the nuances of the design, which will significantly speed up the immediate assembly process.

Frame

If all the preparatory steps are completed, you can proceed to work. First you need to make a bearing frame bender. There is nothing difficult. It is made of metal angle or pipes. The material is cut using grinders and structural elements are fastened by welding. It can be added that the physical dimensions of the frame can be chosen on the basis of personal considerations, but at the same time the most optimal frame height will be if it is several centimeters above the belt of the person who is to work.

Tip! If we use the terms of geometry, then the framework by and large is a parallelepiped. Although you can use other options.

Shafts

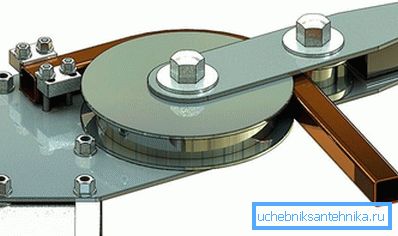

After the main frame is ready, rotating shafts are attached to it. For these purposes, you can use fastening clamps, which are either attracted to the frame with bolts or attached by welding. The general meaning is that the two shafts should be fixed across the top plane of the frame. If the shafts are made independently, then as an example, you can cite steel scrap of the desired length, on which ball bearings are put on both sides.

Next, you need to make a small auxiliary structure for the installation of the third shaft. The idea is that it should be installed in such a way that it can be moved in a vertical plane. To do this, it is attached to a special metal frame, with adjustable height. A handle is attached to this shaft to rotate it. For greater reliability of the design and facilitate the work with the device, all the shafts can be additionally interconnected by means of a chain transmission. To do this, the stars are welded to the shafts. The result is that when you rotate one of them, all three will rotate.

Completion of work

As the final stage of the work, it is possible to carry out external processing of the entire device. This refers to his painting or coating with another anticorrosive composition. As for the manufacture of devices used mainly metal, such processing is necessary. After that, the pipe bender can be considered ready.

The device will work as follows:

- Shaft mounted on a tripod rises.

- A pipe is inserted between it and the two shafts on the frame.

- The upper shaft falls to the plane of the pipe and is fixed with a slight pressure on the surface.

- Using the handle, the shaft rotates, and the pipe moves between the shafts, receiving a certain load on the side, while acquiring a small bending radius.

- Then the shaft is tightened a little more, and the pipe is pulled in the opposite direction, and the bending radius increases.

- The procedure is repeated until the pipe has taken the required bending radius.

You can add that in order to improve the adaptation and facilitate the work with him, it will be quite useful to attach an electric motor to the machine. Thanks to its use, the work will be carried out much faster and easier, but at the same time there will be linkage to the power grid and extra kilowatts on the meter.

It is rather simple to make the manual pipe bender. Moreover, thanks to this, you can save quite a decent amount, because even if you buy all the materials for manufacturing, the issue price will be several tens of thousands of rubles less than the purchase of the finished option. If all the necessary tools and materials are at hand and there is some experience in dealing with all of this, work can be carried out over the weekend.

In conclusion, it should be added that the work on the manufacture of pipe benders is potentially traumatic, and therefore safety regulations are mandatory and must be strictly followed.

Read articles describing other pipe operations:

- How to bend a copper pipe.

- How to weld a profile pipe.

- How to cook electric welding pipes.

Video

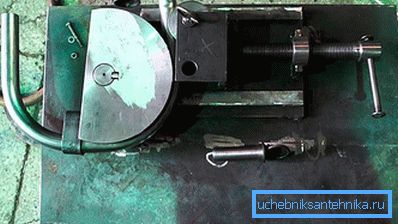

The author of the video made a manual pipe bender from the metal purchased at the scrap metal receiving station. In this video, complete instructions for assembling such a pipe bender.

This video shows how to make a simple pipe bender in the garage: