Pipe coupler - a universal tool for solving many problems

Coupling the pipe coupling is the most practical solution for laying long lines. Any highway has bends, so the need for such an element is very high. Therefore, we will tell you about it further.

Species

To date, there are a variety of couplings for connecting pipes. They are designed to solve certain problems.

Therefore, you should get acquainted with each species.

- Metal polymer - applied quite rarely. Serve for splicing short segments. Coupling for metal pipes acts as an adapter on the thread.

- Polypropylene - are, perhaps, the most simple option in their field. It is a piece of thick pipe that has a larger diameter.

- Couplings for plastic pipes differ from the above in the presence of rubber seals. They are used for laying all types of communications. It is worth noting that when using such fittings it is necessary to use a sealant to impart density.

- Cast iron - used mainly for sewage. There are two types: with a seal and under chasing.

- Steel coupling There may be two types: threaded and compression. The first is a thick cylinder made of steel with one-sided thread. The second involves the use of a rubber ring and a cap nut.

Assembly rules

With the main classifications we figured out, now consider how to connect the two pipes coupling. Naturally, we consider the installation features for each variety.

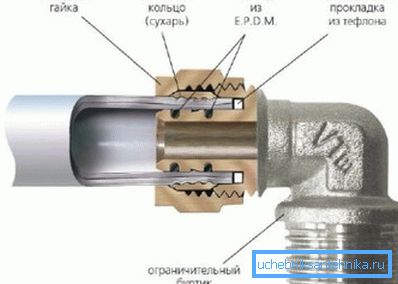

Metal polymer

The connection of metal pipes by coupling is as follows:

- On the external thread we wind flax soaked with linseed oil and lead red lead. This should be done in a clockwise direction. Such a measure ensures maximum reliability and durability.

- Then with a little effort we wind up the adapter. To perform this task, use the open-end wrench or adjustable wrench. If you have never done such procedures with your own hands, it is better to use a wrench.

- Next, put on the flare nut and ring. This procedure will provide chamfering.

Note! Do not slide the ring from the fitting!

- Now we put on the pipe fitting. Holding the body of the fitting with a wrench, it is necessary to tightly tighten the union nut.

That's all, when performing work, show maximum accuracy, and then you will certainly achieve a positive result.

Polypropylene

The next variety that our instruction will consider is polypropylene fittings. This technique involves the use of welding.

It looks like this:

- The inner chamfer is removed from the fitting and the outer chamfer from the pipe.

- On a special soldering iron set the temperature of 265-275 degrees and fix the corresponding nozzle. If there is aluminum reinforcement, it is cleaned with a shaver.

- Next, the elements needing the connection, is inserted into the nozzle. Couplings for connecting plastic pipes can have different shapes, so stock up on a variety of nozzles for a soldering iron.

- After waiting some time (depending on thickness), they need to be connected to each other and fixed. As a result, they are very securely fastened.

Cast iron and copper

This type will require some skills and maximum accuracy from you. Remember that the price of even the slightest mistake in this case is very high.

So, the procedure is performed in the following sequence:

- For compaction, it is best to use a cabal - this is a special fiber that is impregnated with oil. However, you can use other methods.

- Insert the pipe all the way into the coupling. Otherwise, the seal may simply fall out.

- Mint cabbing should be a few turns - this allows you to seal it around the entire circumference.

Tip: if you do not have the appropriate tool, you can use a steel rod with a crushed end, or a screwdriver.

When the joint is maximally compacted, it should be lubricated with cement mortar. It is with such a difficult method that the couplings for copper pipes are fixed.

Steel

Steel fittings come in two varieties: threaded and compression. They are quite different from each other, so each of the types should be considered separately.

Threaded

It is a thick cylinder with one-sided thread. The connection is made as simple and easy as possible: the pipe is twisted on the both sides of the fitting by means of a thread. Remember that metal thread gives the maximum degree of sealing.

Note that the steel allows you to absolutely not be afraid to use force when tightening. However, this material carries one significant drawback - over time, the elements stick to each other. As a result, after some time it will be extremely problematic to disassemble.

This drawback is very significant. In this regard, such materials as cast iron and brass, which do not have this property, are often used for the manufacture of fixation elements.

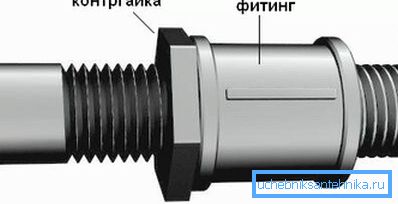

There are cases when the elements during installation do not have the ability to rotate around its axis. In such situations comes to the rescue, the so-called connection with the gantry.

It is implemented as follows:

- The first step is to screw the coupling and the special nut onto the (long) threaded thread.

- Then the short one needs to be screwed into the valve (or any other element that needs a connection). Also, do not forget about the use of various methods of sealing in order to improve the quality of the work performed.

- External thread must be reeled.

- After that, the clutch is driven to it.

- Finally, a locknut is fitted, which ensures maximum tightness. Similarly, do not forget about the sealant.

Compression

As already mentioned, such a connection involves the use of a cap nut and sealing ring. Such fittings slightly resemble metal-polymer. The method of attachment is almost the same.

Nevertheless, we note the main features of this mount:

- It turns out easily detachable. Simply put, after a while, if necessary, you can disassemble the fixed elements without effort.

- It does not need a thread.

- When using this method, it is necessary to process the external surface of the element being joined. In particular, it is necessary to remove paint and rust, as well as get rid of existing irregularities.

- The resulting product is not very reliable. If a small load occurs, the pipe may break out of the fitting. Therefore, when using this technique, you should take care of additional fixation.

findings

At this point we will summarize our story, but if you have not managed to understand all the subtleties, then do not be discouraged (see also the article Hot-Rolled Pipe is an ideal solution in difficult situations).

In the presented video in this article you will find additional information on this topic. Looking at it, you will certainly be able to understand everything.