Pipe coupling: what is needed, how to choose and how to

Upon closer examination, the pipe coupling is a very simple product. In fact, this is a kind of connector for two pipes of the same or different diameter. Also, this product is designed to connect highways, which are made of different materials (for example, it can be a docking of plastic and steel).

However, despite the simple principle of the device, very often it is chosen incorrectly. This is mainly due to the fact that there are too many modern fittings on the market, which are mounted somehow out of the box, or they have a set of some unique properties.

And very often, due to unaccounted individual characteristics, the normal operation of products in a particular situation becomes simply impossible.

In this article we will try to consider as much as possible what kind of products of this type are, how they differ from each other and how to mount them to one or another pipe. Let's start with the most important thing.

Types of couplings depending on the type of connection

In this case, we mean that all the adapters, although they have the same function, but the method of fixation may be different. Consider everything in detail in the table below.

| Fastening method: | Features: |

| It is, in fact, a spike of elements and this technology is used for plastic systems. The advantage of the method is that the connection is very tight and reliable. If the master does everything as it should be, then no leakage will ever appear in the joints. As for the flaws, then we can distinguish such a moment as an incorrect spike. If the time of plastic melting temperature is exceeded by at least a few seconds, then after mounting the fitting, there is a high probability of cracks. Well, if the soldering iron acts on the part less than necessary, then the strength of the connection will be low. |

| Well, everything is quite clear here - a fitting of this type is made of metal, as a rule. The detail is simply wound on the end of the metal pipe. Plus technology is the low price of such work and its simplicity. It is quite possible to do everything with our own hands without the involvement of specialists and without buying an expensive instrument. But the drawbacks of the method are that you will have to constantly monitor such seams, as there is a big risk of their depressurization. Therefore, in no case should a threaded pipe coupling be embedded in the walls, for example. |

| It is mainly used for joining lines through which water or some air flows. The essence of the connection is that the connector snaps onto the ends of the pipes with the help of special nuts of the karabiner type. It is possible to make such a seam quickly, but its tightness and strength are not very good. |

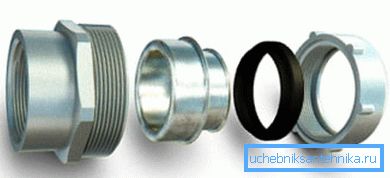

| The principle of operation is that the pipe is put on a special pipe inside the connector. The fitting itself, as a rule, has a nut that clamps, fixes the coupling on the pipe. These connectors are able to withstand a lot of pressure, you just need to ensure that there is a quality coupling for the pipe - the metal hose, by the way, the pipe itself must also be durable. |

There may be rubber seals inside the coupling that are very sensitive to temperature changes. If the rubber inside the product is of poor quality, then as the temperature changes, more and more microcracks will gradually appear on it. And this, of course, will affect (for the worse) the tightness of the connection of the pipeline elements.

Tip! We recommend not to save on fittings of this type and purchase products of well-known, time-tested brands.

As for the scope of the couplings, today they are widely used to connect such systems:

- For water pipes.

- For gas lines.

- For heating mains.

- For oil pipelines, etc.

It is obvious that in the conditions of a private house or apartment the most often used fittings are to dock heating pipes or to feed / drain water. Let's take a look at how such parts are usually mounted and what is important to consider.

Assembly line with clutches

It should be noted that the instruction on the device of joining plastic, metal-plastic and ordinary steel pipes will be considered. Because in most situations, products made from this material are used in particular cases. Let's start with the installation of the metal.

Steel pipe connection

As it is known, earlier joining of highways from steel was carried out by a rather complicated method - using gas or electric welding.

It is quite clear that this technology has certain disadvantages - we will consider them in the table below.

| Problem: | Features: |

| That is, simply speaking with their own hands to perform such work is almost impossible without experience and expertise. tool. Therefore, welding is at least expensive. Although quite reliable. |

| That is, if you have a tile on the walls or, for example, wallpaper, then sparks from welding can easily make the surface unusable. |

Tip: to reduce the likelihood of damage to the plane, you can use a simple method - if it is technically feasible, then try to “close” the potentially vulnerable surface with cardboard or plywood.

In principle, today there is a connection that allows you to do without welding at all - this is Gebo’s coupling on a metal pipe.

It belongs to the class of products with crimp nuts and works according to the following principle:

- The ends of steel are cleaned with sandpaper with a fine fraction.. In this case, the pipes can be made of completely different metal - this will not affect the density of the connection.

- Crimp nuts are put on both sides of the rail..

- The steel is placed on the tip of the adapter, and after that the nuts are attracted to the coupling and twist.

In addition, parts Gebo can have a slightly different principle of the device. The adapter can be made of two elements that seem to be "taken in a vise" the ends of the line. In this case, both halves of the fitting are tightened with the help of external bolts and nuts.

In principle, if the task is to organize an airtight connection without welding, then the use of such fittings is very helpful.

The disadvantage here is that there is no strength, so to say "solidity" of the line. That is, in the joints where Gebo’s couplings are used, the line can be easily broken. Therefore, try in such points to make additional wall fasteners for plumbing.

What else is worth noting is the fact that there are also sleeveless casing of metal, which can also be connected without welding and even without any fittings. The point is that such products have an internal thread on one side and an external one on the other - that is, they simply twist with each other.

We dealt with the metal, now let's see how to connect plastic systems of various types.

Connection of metal and plastic as well as polypropylene

The surest way is, of course, to spike pipe elements. This technology is used not for flexible bay products, but for even polypropylene ones, as a rule.

Everything is done approximately according to this scheme:

- A special soldering iron is taken, turned on and heated to the desired temperature.

- The ends of the pipes are wiped with a dry cloth - it is absolutely necessary to remove all dust and dirt from the plane.

- A plastic adapter and the pipe itself are taken, and then they are, as it were, placed on the heated tips of the soldering iron. It takes about 3-4 seconds to influence the material, and then it is necessary to sharply “remove” the plastic parts from the soldering iron and insert the products into each other.

After that, you should press the elements together and with an effort to hold them for at least several seconds. During this time, the plastic will harden and you will get a very tight coupling connection.

Note! Working with a soldering iron implies one important nuance - depending on the diameter of the pipe, the heating time of the plastic varies. In principle, such data should be contained on the inside plane of the lid of the case, but in case there are none, feel free to use the data from the table below.

| Element diameter (in millimeters) | Soldering iron interaction time | Docking time (“with effort”) of plastic with each other | Cooling period |

| sixteen | 5 sec. | 4 sec. | 2 minutes |

| 20 | 7 seconds | 4 sec. | 2 minutes. |

| 25 | 7 seconds | 4 s. | 2 |

| 32 | 8 seconds | 6 | four |

| 40 | 12 sec | 6 | four |

| 50 | 18 sec | 6 | four |

| 63 | 24 | 8 s. | 6 |

| 75 | thirty | ten | eight |

Well, it remains to discuss how plastic sewer joints, as well as flexible metal-plastic products, are joined together.

In the first case, the instruction is something like this:

- A fitting is taken and a special rubber seal is inserted into it.

- The edges of the pipes are wiped with a cloth, and if one edge is a cut end, then it will need to be polished with fine fraction sandpaper.

- The edges are smeared with a thin layer of sanitary silicone. This is necessary to ensure that the tightness was at a height, as well as for easier entry of plastic inside the coupling.

- Elements of the system are inserted into each other. According to this scheme, the entire "highway" is assembled.

As a rule, a standard rigid adapter is used to connect such a line, but in some cases a flexible coupling for a pipe can be used. To connect the toilet and sewage, for example, or to dock the knee from the sink to the point of entry into the drain system.

As for the technology of docking flexible metal-plastic, then this issue can not be stopped separately, since in most cases the above-described sleeve adapters are used. That is, those in which the ends of the "track" are inserted, and then clamped with special nuts.

Conclusion

It turns out that we got acquainted with a fairly inexpensive and very reliable method of joining the most diverse pipelines. It is especially important to take into account in order to achieve maximum tightness, since this is what type of pipe coupling is purchased, what are its operational characteristics and purpose.

We gave you the basic data, we hope that they will be useful to you in business. Well, if the information was not enough, we recommend that you also watch the video in this article.