Pipe cylindrical thread: a description of the main technical

The threaded connection to this day is considered the most reliable and easy to use. Understanding the technical features and methods of cutting will help you use it more effectively. Next, we present all the necessary information for this.

Main provisions

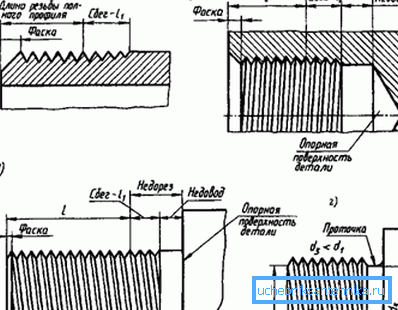

A thread is a specific sequence of helical grooves with a given diameter and repeating pitch. It is applied on the surface of a cylindrical shape to connect various pipe products.

Advantages of threaded connection

The comparative table shows the advantages of screw fixing over alternative methods:

| Connection method | pros | Minuses |

| Welding | Full tightness, reliability | The need for an expensive welding machine and skills to use it, damage to the zinc layer in the field of welding, the complexity of the subsequent dismantling |

| Fitting | Ease of use with their own hands, sufficient tightness | Application is possible only for plastic pipes that have temperature and mechanical operating limitations. |

| Thread | Universality, simple application instruction, high reliability | Need additional sealing tow |

As you can see, welding has many disadvantages associated with the implementation and subsequent state of the pipeline, and fittings can not be used on metal structures. The only lack of threading is quite conditional, since the price of tow, which creates an additional item of expenditure, is insignificant.

Specifications

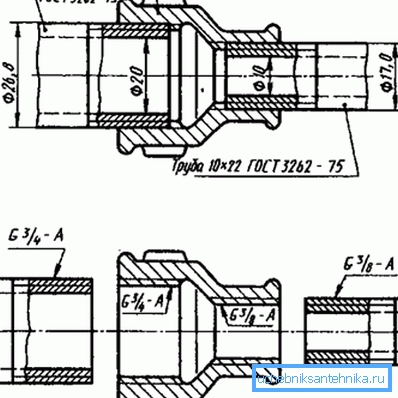

Now let's consider the main parameters of a pipe cylindrical thread, which are regulated according to GOST 6357 81:

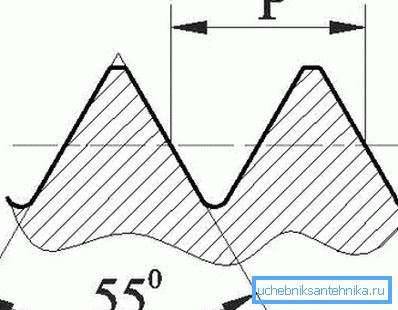

- Profile angle. In this variant of cutting, it is equal to 55 degrees.

- Outside diameter - the distance between the two highest points of the threaded profile.

- Inner diameter - the distance between the lowest points of the threaded profile.

- Nominal diameter - parameter to calculate the stiffness and throughput of the pipe. It is denoted in inches and is related to internal and external as follows:

| Nominal diameter, inches | Corresponding outer diameter, mm | Corresponding internal, mm | |

| Minimum value | 1/16 | 7,723 | 7.142 |

| Maximum value | 6 | 163.83 | 162,351 |

Be aware: when connecting plumbing it is exactly the nominal diameter that is taken into account. The remaining data is required only in the manufacture of threaded connections.

- Step - the number of helical grooves per inch. Can take values: 11, 14, 19 or

Control

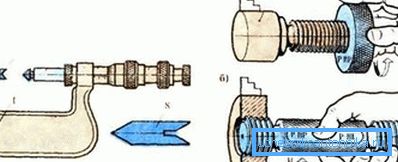

The accuracy of the thread geometry is checked in one of two ways:

- Caliber. A blank with adjusted parameters is taken and screwed onto a new thread or screwed in if it is an internal connection. If defects and discrepancies are found, the blank will not reach the end of the product.

- Template. In this case, the case is limited by the fact that a flat plate is applied to the thread, and if there are no gaps, then the product is considered fit.

Tip: if necessary, a quick check is recommended to use a template. Control with the same caliber, though more accurate, can significantly delay the process.

Cutting methods

There are two ways of threading:

Mechanical

Implemented with the help of special machine equipment:

- In the cartridge set the steel billet.

- On the caliper fix the cutter and adjust it to the desired angle profile. Tool for external cutting set perpendicular to the workpiece, and for internal - parallel.

- We start the car and control the cutting.

The machine will take a product of any complexity, allow you to do the work quickly and efficiently, but not always be at hand. Therefore, you should consider another, simpler option.

Manual

Every self-respecting plumber always has a screw die or pipe dies for cutting external threads and a tap for internal ones.

Such tools allow you to carry out your plans in any conditions, it is enough:

- Install suitable cutters on the pipe screw die and the handles on the die or tap.

- Then slightly grind off the end of the pipe.

- Fix the tool on or in the product.

- Slowly and evenly scroll to full aisle.

- Feed the machine back to the finished thread.

Both methods require some skills, but they are quite affordable.

Conclusion

High-quality and durable plumbing is installed using threaded connections. This is a time-tested method that has not yet lost its relevance.

Above, we have analyzed the possible technical parameters of a cylindrical pipe thread according to the current State Standards. It is also important that the necessary threaded grooves on the pipe can be made independently, using the machine, die, die or tap.

The video in this article will provide you with some additional information that has a direct bearing on the materials presented.

Knowledge of threaded connections helps to use them more effectively.