Pipe d16t: standard and material features

By what standards is produced thin-walled and thick-walled tube D16t? What material is it made from? How does this material differ from alternative solutions? Let's figure it out.

Raw material

First, let's separate the flies from the chops. D16t is the marking not of the pipe itself, but of the alloy from which it is made. Like all aluminum alloys, ours are notable for their low density (about 2800 kg / m3).

The main disadvantage of aluminum is the low mechanical strength to a large extent leveled by the addition of other elements of the periodic table.

Composition

According to GOST 4784-97, alloy D16 has the following composition:

| Metal | Mass fraction,% |

| Fe | Up to 0.5 |

| Si | Up to 0.5 |

| Mn | 0.3 - 0.9 |

| Cr | Up to 0.1 |

| Ti | Up to 0.15 |

| Al | 90.9 - 94.7 |

| Cu | 3.8 - 4.9 |

| Mg | 1.2 - 1.8 |

| Zn | Up to 0.25 |

| Third-party impurities | Not more than 0.15 (maximum 0.05 each) |

Note: the amount of aluminum in the alloy is given approximately. This metal is the base; under certain conditions, the upper limit of the content shown in the table may be exceeded.

So, the main components of the alloy - aluminum and copper.

What characteristics does such a composition provide?

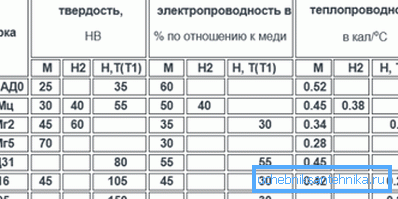

- D16 is noticeably harder than pure aluminum. However, like all duralumin alloys.

- Strength is fully preserved in the range of up to 250 degrees Celsius. Actually, in the range of 120 - 250C, this alloy is unparalleled among all types of duralumin.

- The upper limit of short-term heating is about 500 ° C.

Post processing

Perhaps the reader drew attention to the fact that the name of the alloy - D16 - differs from that in the title of the article D16t by the absence of a letter at the end.

It means a post-processing method. The following options are possible:

| Marking | Description |

| T | Hardened and naturally aged alloy |

| T1 | Artificially aged |

| M | Annealed |

| BUT | Plated |

Useful: in the price lists of manufacturers can be found type marking D16TA. This denotes a hardened alloy, natural aging, and (after the formation of the part) plating.

Terminology

Some terms probably need clarification.

- Annealing is heating to the recrystallization temperature (in our case, to about 500 ° C), followed by slow cooling. Without going into the physics of the process, we note that the annealing gives metals a high ductility and toughness, and at the same time relieves internal stresses in the metal structures.

- With rapid cooling from the recrystallization temperature to room temperature and below, the physical properties of the metal change in a different direction: on the contrary, it becomes extremely hard. The process is called quenching.

- Plating is the application of a layer of pure aluminum to the surface of the alloy. The fact is that it has greater corrosion resistance than many of its alloys; plating performs a protective function.

But the process of aging of the alloy is so curious that we will dedicate a separate section to acquaintance with it.

Aging

At the beginning of the 20th century (more precisely, a decade before the First World War, in 1903), German material scientist Alfred Wilm, an employee of the metallurgical factory Durener Metallwerke AG, discovered an unexpected phenomenon in the process of studying the properties of aluminum.

The alloy of 96% aluminum with 4% copper after quenching, like many other metals, was predictably made harder and stronger. However, the process did not stop when the alloy reached room temperature: at 20 ° C for the next 4-5 days, the metal continued to gain strength without losing plasticity.

The alloy was named duralumin (in honor of the German city of Duren, in which it began industrial production in 1909), and its composition and heat treatment technology were quickly classified: the first time it was massively used for the construction of military airship frameworks.

Shelila, however, cannot be concealed in a bag: by 1920, duralumin became the main material in aircraft construction around the world. In the course of the experiments, another interesting property of the alloy became clear: the process of gaining strength can be dramatically accelerated, heating it to 188 - 193 degrees after quenching.

In this case, the maximum strength was achieved in 11–13 hours, which, of course, from the point of view of manufacturability, looked much more advantageous.

How strong is the D16t alloy against pure aluminum? Let's compare their resistance to compressive stress: aluminum is capable of withstanding 7-8 kg / mm2, and duralumin 45.

About the alloy is useful to know a few things.

- Its welding is very problematic. As a rule, rivets are used to join sheet parts with their own hands.

- The rivets themselves often make all of the same D16t.

- The priority area of use of the alloy - aircraft; less commonly, it is used for the needs of the automotive industry - mainly in the manufacture of bodies.

- It can not be called cheap material. The price of the notorious pipes from this type of duralumin is from 500 rubles per kilogram.

GOST 18482-79

In fact, back to the pipes. They must be made according to GOST 18482-79 Pipes extruded from aluminum and its alloys.

Let's explore the main points of the document:

- Pipes can be both round and shaped.

- The standard provides for the division of wall thickness only into thin-walled (wall up to 5 mm) and thick-walled (over 5 mm).

- The outer diameter for a circular cross section according to the table of the assortment contained in the standard can vary from 18 to 300 millimeters.. The maximum permissible deviations from the nominal size increase with increasing diameter and take values from 0.5 to 2.8 mm up or down.

- The wall thickness can be up to 93.116 millimeters with a diameter of 300 millimeters.

Note: the range table is not an unbreakable canon. By agreement with the supplier, additional dimensions may be entered; The tolerances are taken as for the smaller of the nearest diameters.

- Length of products - from 1 to 6 meters: unmeasured, measured or multiple measured. In the latter case, the general for most similar standards is the instruction: a 5-mm allowance is made for each cut. Curiously, pipes from softer alloys can be supplied in coils up to 15 kilometers long.

- Products with a wall thickness of more than 10 mm and an outer diameter of 100 mm should not have any burrs on their outer surface.

Conclusion

We will consider our acquaintance with the new material held. We hope that it will be useful to the reader (see also the article Pipe for a warm floor: how to choose the optimal variety and correctly lay it).

As usual, the video in this article will offer him more information. Successes!