Pipe distribution in the bathroom: how to do it

To date, the distribution of pipes in the bathroom is considered polypropylene as the main method of installation, although it is still possible in some cases to use metal and plastic. Nevertheless, PP has proven itself as a quality material for transporting both cold and hot water, although there are some nuances in the selection of the design of the pipe itself.

Below we will discuss with you which polypropylene is used for this purpose, how it fits and fastens, and also show you the thematic video in this article.

Plumbing fixtures for the bathroom

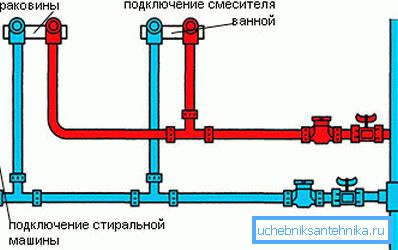

Note. It should be noted that the layout of pipes in the bathroom with their own hands automatically affects both the toilet and the kitchen - because the whole system is a single whole. This applies not only to hot and cold water, but also to sewage, which is also a complete system connected to the drain riser.

Materials and tools

- For supplying cold water from the main line to sanitary facilities, a boiler or a boiler, the instruction allows using a polypropylene (ecoplast) pipe with a monolithic wall and, if we speak about household use (private house or apartment), then a material with an external cross section of 20 mm is used. However, most of the masters in this case tend to use reinforced ecoplast, which is intended for hot water supply.

- The pipes are reinforced with fiberglass or aluminum foil - this layer is placed in the middle, as shown in the schematic figure above. Such a measure prevents deformation of the material during heating, therefore, similar products are also used for heating. Despite the fact that the price of reinforced pipes is higher, they are used for cold water supply with the purpose of reinsurance - in most cases the system is made of a hidden type, closing it with plaster, putty, drywall and so on.

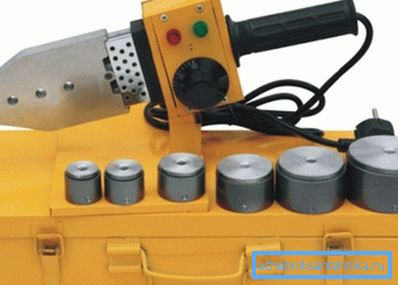

- For welding PP uses a special soldering iron, complete with which supplied nozzles of different diameters. The quality of this tool is determined by the presence of the thermostat, as well as whether the tips have a Teflon coating (this directly affects how much the soldering iron costs). The fact is that polypropylene does not burn on Teflon, therefore, in the process of work there is no sticking of material and soot.

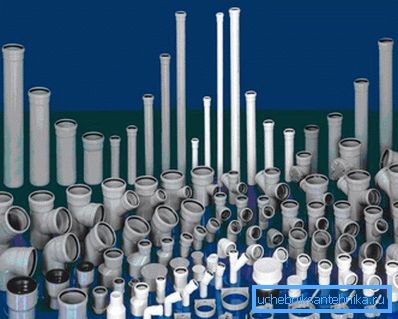

- In addition, the layout of pipes in the bathroom and toilet also includes sewers, for which products with a diameter of 10 mm are used. 50 mm, 32 mm, as well as connecting, turning and decoupling fittings to them. At present, both at the household and industrial levels, polyvinyl chloride is used for manufacturing, although steel, cast iron and bronze are still found. However, PVC is much cheaper and lighter, and for low pressure pipes it is perhaps the most profitable and practical.

Installation of sewage

As we have already said, distributing pipes in the bathroom with their own hands also affects the toilet and the kitchen, because the drain will occur from the kitchen through the bath and end up in the toilet riser, regardless of whether you have a joint or separate.

Let's start with the toilet - if you left an old cast-iron riser there, you still have to put a tee there with one 100-mm tap on the toilet and 50-millimeter - on all the other bathrooms. A rubber reduction is used to install a plastic fitting in a cast-iron socket, which serves as both an adapter and a seal.

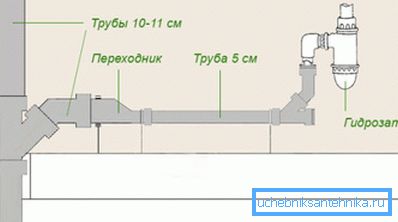

The 50-mm tap is placed in the direction of the kitchen and passes through the bathroom, and tees for draining from the sink, bathtub and kitchen sink are slammed into its length.

The automatic washing machine can be connected to a special siphon, which you can use under the bathtub, sink or sink, but you can also make a drain - a reduction for the 32 mm pipe that you lay in the right direction is inserted into the socket of the 50 mm tee.

Note. A pipe of 50 mm should have a slope of at least 30 mm / 1 m, 100 mm (if there is a horizontal position) -20 mm / 1 m, and 32 mm for the machine can be put without a slope, since there is forced flow.

Installation of water supply

Now let's look at how to properly arrange the pipes in the bathroom, toilet and in the kitchen with external and internal installation. Under the polypropylene, you can make the grooves and hide it in them, as shown in the top photo (after that the water supply system is sealed with mortar), but you can also put it on top by fixing it in metal brackets or plastic clips.

When marking, try to ensure that all threaded fittings for connecting to valves have the most advantageous position and are firmly fixed.

We are considering how to do the pipe installation in the bathroom, and now we will pay attention to the soldering work, through which polypropylene is joined through fittings of different configurations.

A soldering iron heated to 280-290? C is attached to one side of the pipe, and on the other, the fitting is held for 5-6 seconds (make sure that the pipe does not sink into the nozzle deeper than 15-20 mm), then simultaneously removed and joined. After docking, it is also desirable to hold them for 5-6 seconds, so that they become a homogeneous mass.

Conclusion

In conclusion, it should be said that the correct wiring of pipes in the bathroom for hot and cold water is carried out in blocks, that is, whole sections with tapes are soldered, and then connected together - this is much easier. But the sewer is mounted, joining at one time no more than two or three elements collected together.