Pipe dks - the characteristic, device and mission

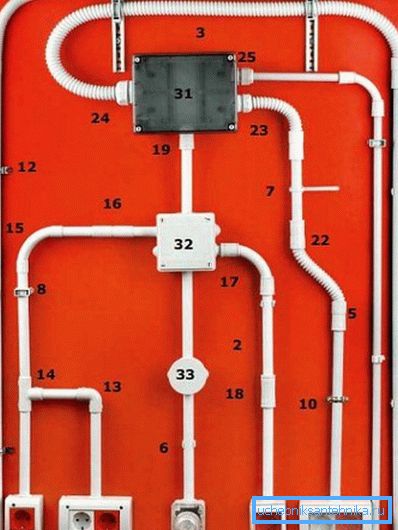

If you need to build communications that will protect the electrical cable, you should pay attention to the pipes DKS, made of polymeric materials. They are also well proven in the organization of stocks. In this article, their types will be considered, including DKS flexible reinforced pipe for laying engineering networks in various buildings and premises.

What it is

Let's take a closer look at the product. It looks like a cylindrical profile construction, hollow inside. Such constructions can be met in different fields of activity, so that they are part of our life. For example, without them it is difficult to imagine modern plumbing, sewage and heating systems, electricity is also associated with the use of pipeline fittings.

DKC pipes for electrical wiring can be varied, in particular:

- tough;

- flexible;

- metal;

- polyethylene.

Because of this, they can be used in different industries, as each species will have its own use. Today we look at corrugated flexible pipes DKS for cable systems.

Tip: you can use computer, television, electrical, and telephone cables for laying them in the cavity.

At the same time, it is necessary to ensure that the voltage of direct or alternating current in such networks does not exceed 1000 V. Wiring should be made of low-flammable or non-flammable cables and wires.

Applies an open, half-hidden and hidden way to install it. Laying can be carried out in stationary household electrical installations that can be operated in open spaces and indoors.

Kinds

Corrugated flexible pipe system DKS can be:

- single wall;

- double wall

The latter consists of an outer layer (corrugated from HDPE) and an inner layer (LDPE). The smoothness of the latter is necessary to reduce the degree of friction that is created as a result of operation between it and the cable located inside.

Such a double-wall corrugated pipe of the cable system makes it possible to protect the latter from mechanical damage and the negative influence of the environment. The system allows laying under the ground or with a water cable having a large cross section.

Classification of corrugated DKC products for wiring may be as follows:

| Series number 7 |

|

| Series number 9 |

|

| Series number 10 |

|

Material

In the manufacture of pipes using a variety of materials, including polypropylene, which showed itself well in 10 series.

From its properties can be identified:

- wear resistance;

- ability to resist chemicals;

- excellent electrical insulating properties.

In addition to pipe fittings, it is also used to produce:

- different packaging;

- items and parts for domestic use.

Polyvinyl chloride for pipes of 9 series is resistant to acids, alkalis and various solvents. In addition, it is fire resistant, moisture resistant and resistant to wear. The life of the product is more than half a century. The material is environmentally friendly and does not emit toxic substances, which can be considered another advantage when choosing.

For the 7th series, low and high pressure polyethylene is used. Also double-walled corrugated pipe is made of them.

For such products it is typical to be:

- resistant to acidic environment;

- reliable in operation;

- immune to UV radiation and negative climate.

Useful information

A conduit system is a closed construction, which is assembled from special cable-carrying pipes and corresponding accessories. It is used to protect insulated wires, as well as electrical cables, communication systems and alarm systems, telecommunication installations, laid in them.

Below are the requirements that must be met cable sewage system:

- minimum length;

- the minimum possible number of intersections with roads, street drives, railway transport and tram routes;

- providing easy access to cables, minimal costs during the operation of the line, the possibility of increasing its throughput;

- the master plan of engineering communications for a period of 5-10 years should be taken into account.

Tip: Cable ducts DKS are used for laying cables with lightweight protective sheath, including without metal armor. At the same time the price of installation of lines is significantly reduced.

Conclusion

The use of DCS system pipes in laying electrical cables and other communication networks can significantly reduce the cost of installation work. The industry produces two types of such products - single-layer and two-layer.

There are also various series of DKS pipes made of different materials and used for their intended purpose. The video in this article will help you find additional information on this topic.