Pipe fittings: types and device

This article is a brief overview of the main types of water fittings on the market. We have to get acquainted with their appearance and device. In addition, we will touch on the basic principles of fitting fittings installation in each specific case.

So go ...

One-piece fittings

All types of welded and soldered joints fall into this category.

Copper

Copper pipes and fittings for heating and water supply systems are mounted by soldering.

What does this process look like?

- The pipe and fitting are heated with a gas burner and are cleaned of oxide film with the help of flux.

- Then in the torch of the burner a bar of solder is brought to the socket. Due to the capillary effect, the melt fills the entire cavity. After cooling, the connection remains tight.

Please note: copper plumbing can also be assembled on collapsible fittings, the construction of which we will consider later.

Polypropylene

Fittings for propylene pipes are mounted by low-temperature welding using a soldering iron, heated to a temperature of 240 - 250C.

- The end of the pipe is placed in the socket of the soldering iron. At the same time, the fitting is put on the second part of the heating element of the corresponding diameter.

- After the surfaces are melted, they are combined with a smooth forward movement. Rotation and any displacement after the pipe is inserted, under a strict ban: they dramatically worsen the quality of soldering.

How long the pipes and fittings for PP pipes should heat up and cool down depends on their diameter.

| Nominal diameter, mm | Heating time, with | Duration of welding, with | The duration of complete cooling, min |

| sixteen | five | four | 3 |

| 20 | five | four | 3 |

| 25 | 7 | four | 3 |

| 32 | eight | four | four |

| 40 | 12 | 6 | four |

| 50 | 18 | 6 | five |

| 75 | thirty | eight | eight |

Nuance: aluminum-reinforced pipes before welding are cleaned from the reinforcing layer at the site of the future connection.

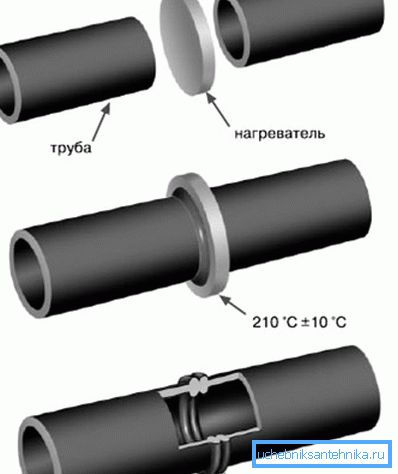

Polyethylene

Polyethylene plumbing pipes and fittings for welding are also connected using a low-temperature soldering iron; however, the joint is not flush but flush.

- The ends of the connected parts are pressed against the surface of the heating element.

- After melting, they are joined to each other and held for a few seconds with a small hold-down.

Mechanical and hydraulic devices for centering and clamping are used for large-diameter pressure pipelines and pipes: its force can reach hundreds of kilograms.

Metal plastic

The so-called press fittings for metal-plastic are mounted without the possibility of subsequent disassembly. The end of the pipe is put on the fitting, fitted with a pair of annular rubber seals, after which it is crimped with a stainless steel sleeve with special pliers.

This type of connection is considered the most reliable and, according to most plumbers, compares favorably with compression in that it does not leak on hot water and heating.

When installing it is worth considering a couple of subtleties:

- The pipe should be perfectly round.. Ovality will lead to the fact that putting it on the fitting, you slide the O-rings.

- In addition, before assembling, it is imperative to remove the inner chamfer. The reason is the same.

Split fittings

Steel

A couple of decades ago, the most common were cast iron and brass threaded fittings; now they, along with steel pipes, are being gradually replaced by synthetic materials. For sealing threaded connections, flax is used (often with paint or sealant impregnation) and synthetic fiber (Tangit Unilok and its analogs).

However: threaded fittings for gas pipes are mounted using FUM tape, which provides excellent sealing at low pressures.

In addition to threaded steel, crimp connections can be used for steel: a cap nut with the help of a stop ring bursts a rubber or silicone seal. The main requirement when using appropriate fittings is a smooth pipe surface and a complete lack of ovality.

Copper

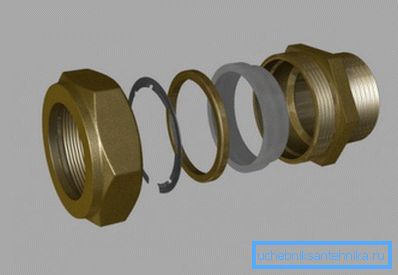

Compression fittings for copper compare favorably with brazed ones by simple installation using the tools at hand.

Only a pair of spanners or wrenches are needed for assembly. When tightening the flare nut, the pipe is crimped with a split ring; tightness is ensured by the plasticity of the metal. For annealed pipes, the design provides a mandrel, which does not allow them to crease when crimped.

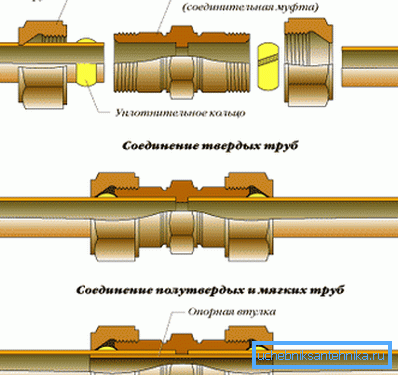

Metal plastic

Compression

Sealing, as in the case of press fitting, is provided with a pair of O-rings. Only the crimping mechanism is different: as in the case of copper, it is provided with a split ring, which is compressed when the cap nut is tightened.

As already mentioned, the compression scheme is considered unreliable: on hot water and heating, after a certain number of heating and cooling cycles, the connection leaks. According to the author, notoriety is absolutely undeserved: a typical reason for leaks is gross errors during assembly.

You see, press fittings require the use of special tongs; the price of the instrument - at least 8-12 thousand rubles - makes it irrational to purchase it for a one-time repair.

From here two practical consequences:

- Installation of metal-plastic with compounds of this type is done by professionals;

- They do not save on other tools and technological operations, in particular, on calibration and chamfering.

Compression fittings are often connected with an oval end sawed off with a hacksaw. In this case, the rings of seals mercilessly pulled out of the grooves and shifted deeper into the body. Tightness provides only polyethylene, which when heated becomes very plastic.

Push

This design differs only in the fixation mechanism of the pipe: it is clamped by a spring ring with inward-pointing legs. Tightness and here is provided by a pair of rubber rings. Hence the obvious instruction: when assembling the pipeline with your own hands, calibration and chamfering are also necessary in this case.

Polyethylene

In addition to welding, compression joints can also be used in the assembly of polyethylene pipelines. For tightness are responsible rubber rings already familiar to us.

Corrugated Stainless Steel

The design of the connection is almost identical to the previous one: the pipe is crimped with a silicone seal when tightening the union nut.

Crosslinked polyethylene

The fitting is a common herringbone fitting. Tightness is ensured by the mechanical memory of cross-linked polyethylene: stretched by an extender, it returns to its previous size within a few minutes.

Conclusion

We hope that the description of designs presented will help the reader in choosing materials for future repairs or construction (see also the article Posting in pipes: installation technology for maximum safety).

As always, the video in this article contains additional thematic information. Successes!