Pipe for a bath: selection, installation and maintenance

In this article, we will talk about how and with what materials a pipe for a bath can be made with your own hands. The topic of the article is not accidental, since the efficiency of heating of the steam room, the efficiency of the heating system and the fire safety of the entire structure depend on the choice of the configuration of the pipe and the materials used in their manufacture.

The easiest way is to seek help from a professional stove, who will calculate the structure of the structure and produce a chimney in accordance with the parameters of the heating equipment. But the price of such a service will be high, and therefore you can try to cope with this task on your own.

What to choose, ceramics, steel or other materials

Modern chimney pipes for the furnace of a bath are presented by the wide range of various products.

Consider the main types:

- Ceramic chimneys are made using environmentally friendly chamotte clay.

Finished products made with the use of such materials are characterized by increased resistance to critical temperature conditions. Thanks to modern production technologies, ceramic pipes are made of light, thin-walled, resistant to the negative effects of environmental factors, including precipitation.

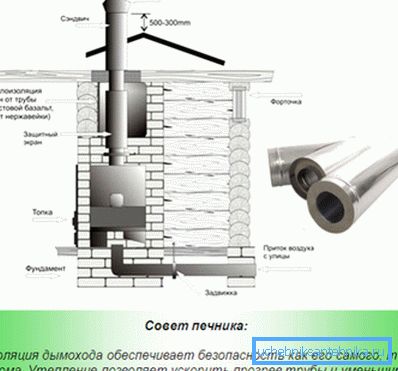

A modern ceramic chimney is a system consisting of an outer shell (outer contour), ceramic chimney pipes, heat-insulating elements and special mounting accessories.

- Steel chimneys - These are lightweight quick assembly constructions. In addition, the price of such products is low in comparison with ceramics and structures made of other materials. The steel tube for the stove in the bath is not as durable as the counterparts made of chamotte clay, but the lower operating life is offset by a more affordable cost.

A significant advantage of steel chimneys is their smooth internal surface, on which soot practically does not precipitate. Sheet steel tubes can be considered the best choice only if they are galvanized.

- Asbestos cement pipe can only be used when you need to save money.

Despite the fact that the price of such chimneys is low, it is not worth purchasing them for use in baths and saunas for a number of reasons.

First of all, asbestos cement is a carcinogenic material that is potentially hazardous to health. In many Western countries, asbestos cement pipes and slate have been banned for sale. In addition, such pipes are not strong enough and their fire safety also leaves much to be desired.

- Glass chimneys in the domestic market are rare and are still perceived as exotic. But, according to experts, pipes made of refractory glass, in the near future, will displace from the market counterparts made of other materials.

The main advantage of glass constructions is an absolutely smooth internal surface, on which no combustion products are deposited. In addition, glass, like no other material is resistant to corrosive processes. But there are also disadvantages; this, as already mentioned, is unavailability in the market and high price.

Choosing an insulator

The best thermal insulation for the chimney in the bath is folgoizol.

This material is characterized by such advantages as:

- environmental safety due to the absence of harmful emissions into the environment in the process of heating;

- ease of installation by hand;

- availability in free sale;

- reasonable price, in comparison with other heat-insulating materials;

- low degree of thermal conductivity, both from the internal and external side;

- absence of condensate in the process of temperature fluctuations;

- durability of operation of the material.

Sizes and configuration

Before you make a pipe in the bath, you need to determine its shape and size.

Regardless of what material the chimney is made of, the length of its horizontal (flat) part should not be more than a meter. Failure to comply with this rule will cause insufficient thrust.

The best cross-sectional shape of the chimney is the circumference. In addition to good traction, this section provides additional convenience to connect to most heating furnaces.

The diameter of the circle should correspond to the power of the furnace used in the bath. Calculate the parameters of the cross-section can be based on the considerations that for every kilowatt of power should be from 8 cm ?.

If a square tube is used in accordance with the characteristics of the heater, the recommended hole sizes are as follows:

- 3.5 KW - not less than 140x140 mm;

- up to 5.2 kW - not less than 140x200 mm;

- up to 7.2 KW - 140x270 mm.

Before you install the pipe on the roof of the bath, you need to determine the height of the structure. The total length of the structure, to create a normal thrust, must be at least 5 meters. In addition, the height is distributed by the type of roofing system.

If the roof is sloping duo-pitch, the pipe should protrude about half a meter above the level of the ridge. If the roof is flat, the pipe should rise about 1 meter above it.

Building a chimney

Steel pipe in the bath with his own hands is built easily, provided that there are all the mounting components.

We will need:

- pipes in a pre-calculated amount;

- fixing clamps;

- hat (umbrella);

- gate;

- support brackets;

- knee at 45 °;

- adapters.

Installation instructions are as follows.

At the initial stage, the cutting of the pipe is done on the ceiling of the bath:

- the size of the pipe in the ceiling cut hole;

- a chimney is placed in the middle of the hole;

- the gap between the ceiling and the pipes is filled with mineral wool or other heat-resistant insulation;

- in the lower and upper parts of the ceiling, sheet metal is stitched to hold the insulation;

Important: Combustible structures should be removed from the inner surface of the pipe at least 38 cm, and from the outer surface - at least 13 cm.

Then the pipe is fed to the furnace and is fixed in accordance with its structural features.

Operational service

No matter how professionally and efficiently the pipe is built in the bath, its operational life depends on the regularity of the maintenance.

If the sudden deterioration of the traction or, for example, smoke penetrates into the steam room during the fire, most likely a blockage occurred in the pipe and it's time to start cleaning.

The clog in the chimney can be cleaned in two ways:

- purchase a special brush, scraper and other devices for mechanical cleaning, climb on the roof and work as a chimney sweep;

- to heat the furnace with aspen wood.

Tip: Burning aspen wood occurs with a lot of heat and a small blockage will clear itself. This cleaning is simple, and therefore it should be periodically carried out in preventive measures.

Conclusion

So, we have considered the main types of chimneys that can be used in the arrangement of baths and saunas. In addition, you now know how to install the most common pipes with your own hands.

Finally, it is not a secret to you how to prevent blockage in the chimney. There are questions that need clarification? More useful information you can find by watching the video in this article.