Pipe for electrical wiring: install secure communications

Plastic and metal pipes for electrical wiring are used almost everywhere. However, most often this method of installation is used in the formation of the electrical network in the house, the load-bearing walls and partitions of which are made of combustible materials. Here, our main task is to protect against ignition, and the use of tubular channels gives us the opportunity to provide this protection in full.

Below we will explain why the laying of wires in various pipes can be used, as well as which materials are better to use for these purposes.

Hidden Mounting Tips

The necessity of using tubular closed channels for laying cables in the walls, under the floor and ceiling is explained by such considerations:

- The main thing in this case is, of course, compliance with fire safety requirements. In wooden houses, as well as in constructions erected by panel technology with combustible insulation in the thickness of the walls, all wires must be laid either in steel or in plastic refractory cases.

- Secondly, the pipes for electrical wiring in a wooden house protect the conductors from damage during structural shrinkage due to the natural drying of the wood.

Note! This is especially true for butt nodes, since at these points an uneven load may act on closely spaced areas of the conductor.

- Thirdly, if the cable is laid under the floor, a steel or rigid plastic pipe will protect it from damage due to operational loads.

- Finally, this mounting technique makes it easy to change conductors. The PVC pipe for electrical wiring with the output to the junction box is very convenient for maintenance, and if we are not too lazy and color-coded the conductors, then difficulties should not arise at all.

As you can see, the arguments in favor of the use of such details are quite enough. We can only pick up specific models in accordance with the features of their operation.

Pipe selection

Plastic varieties

As a rule, for installation of hidden wiring in the thickness of the walls, and sometimes on their surface, plastic or metal cable channels are used. All the varieties used have advantages and disadvantages, and below we will analyze them in some detail.

The most common today are plastic models.

For their manufacture, polyvinyl chloride (PVC) is used, as well as high and low pressure polyethylene (LDPE / HDPE).

- Polyvinyl chloride products are available in a fairly wide range.. The main mass consists of channels with a diameter of 16 to 60 mm, but in some cases thicker pipes can be used. They are characterized by an affordable price, which, together with good indicators of strength and heat resistance makes this variety very popular.

- HDPE pipe for electrical wiring can also be used when finishing rooms with walls made of combustible materials (wood, plastic sheathing, etc.). Polyethylene surfaces are fairly smooth, which makes it easier to replace conductors.

- Standard plumbing fittings are commonly used for mounting such products.. The fact that the tightness of the joints does not necessarily comply with, significantly speeds up the installation process: the plastic pipe perfectly connects to the knee or crosspiece with the help of a socket and a rubber cuff.

The main advantages of technological polymer pipes are their low mass, resistance to corrosion and sufficient strength for most situations. In addition, both polyethylene and PVC are dielectrics, because the cable channel can be safely considered as one of the insulating circuits.

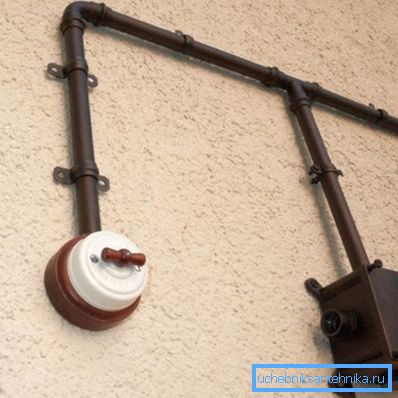

Steel Products

Unlike plastic, steel pipes have a significant mass, but at the same time, they are characterized by the highest strength. In addition, fire safety instructions strongly recommend the use of a steel pipe when laying wires in wooden buildings.

In the selection and installation of such products should follow a number of simple rules:

- The pipe diameter must ensure the free routing of all cables without sealing the insulation sheaths.

- The bends and turns of the tubular cable channel are made in such a way as to prevent the build-up of wires.

Note! The optimum angle of rotation - 900. If at the site you need to make two or more bends, the length of the channel should not exceed 5m.

- The inner surface of the pipe should be smooth, without protruding welds and burrs.

- To minimize the risk of corrosion, it is worthwhile to place the pipes with a slight bias towards the distribution board.

However, the main thing in this case is to ensure electrical safety: steel is a good conductor, because all channels must be grounded, and the state of the insulation of the wires should be monitored carefully.

Copper and brass

Thin-walled copper / brass tube is an excellent choice for both concealed installation and for mounting wires on the wall surface.

There are several advantages to this solution:

- First, neither copper nor brass is as susceptible to such active corrosion as steel products. Of course, over time, a patina layer forms on the surface, but it only slightly degrades the performance properties of the channel.

- Secondly, a wide selection of fittings allows you to do your own handswiring pretty quickly. And thin-walled tubes can generally be bent to the desired radius.

- Finally, copper or brass pipes, mounted openly and carefully polished, can be a real decoration of the interior, designed in vintage style.

However, this solution is still not universal:

- Firstly, these metals have good thermal conductivity, so they need to be placed away from the heating pipes. Otherwise, there is a risk of overheating the wiring and even melting the insulation.

- Secondly, thin walls do not provide reliable protection against mechanical damage: both steel and even high-quality plastic pipes will be stronger than the copper channel.

- There is no need to talk about the cost of such decisions either: if you are looking for an economy option, then neither copper nor brass will definitely suit you.

Technological corrugation

Above, we considered the use of ordinary pipes for our purposes. However, there is an option that is specially adapted for laying cables in the thickness of the wall.

This is a corrugated pipe, which can be made of different materials:

- Corrugated PVC, HDPE or LDPE has all the advantages of plastic. Its ribbed surface significantly increases the mechanical resistance of the whole structure.

- The possibility of channel bending without special tools greatly facilitates and speeds up the wiring of complex configurations.

- A wide range of diameters enables us to choose the channel that is optimal in cross section for both single conductors and whole systems.

- Finally, corrugated metal pipe is an excellent protection against fire. Although, to be honest, modern polymers are only slightly inferior to metal in this parameter.

Conclusion

At arrangement of the hidden communications the most different pipes for laying of an electrical wiring can be used. And if earlier only steel (extremely rarely - copper) products were used for this purpose, today, smooth and corrugated models made of polymers or metal-polymer composites are an excellent alternative to them.

The video in this article contains a number of additional information about such products: first of all they will be interesting to beginner electricians, but a professional can also find something new for himself.