Pipe for geyser: installation and operation features

When installing gas water heaters, special attention should be paid to the issue of removal of combustion products from the room. This will not only ensure safety for those living in the house, but also increase the efficiency and economy of the device itself. Next we look at what to do and how to install a chimney for the column.

Design features

Exhaust pipe device

Before proceeding with the installation of the exhaust system with your own hands, you should familiarize yourself with its structure. So, the design includes the following elements:

| Cap (umbrella) | The topmost part of the system that protects it from rain, debris, etc. |

| Chimney | The main element. It can be both insulated and without thermal insulation. |

| Feedthrough | Isolates the chimney from the wall of the building. |

| Brackets | Designed to fix the structure to the wall. |

| Coupling collars | Installed at the junction of elements. |

| Tee | Provides a transition from the column to the exhaust pipe. |

What determines the design

When constructing an exhaust system, you should pay attention to the following points that may affect its design:

- The conditions under which the chimney will work, as well as the location of the device.

- Column model - the choice of components depends on it.

- Chimney height - must be at least four meters.

- The diameter of the chimney - most often this parameter is 110 and 130 mm.

- Power device.

- Climatic conditions - temperature differences between the products of combustion and the environment are of great importance in the operation of the equipment.

Note! The chimney should rise above the roof at least one meter. This is an important condition on which the thrust force depends. In addition, the length of the chimney from the outlet of the column should be at least two meters.

Hood material

Today, chimneys for gas columns are most often made from the following materials:

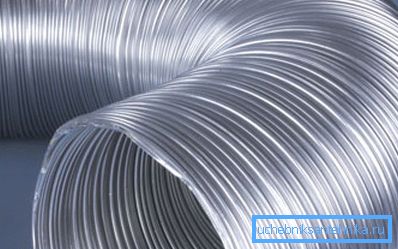

- Corrugated pipe - made of multilayer laminated aluminum foil. Between the layers of aluminum along the entire length is steel wire. Its main distinguishing feature is flexibility, which simplifies installation and the possibility of increasing the length.

- Steel pipe - made of high quality steel. The product is made of segments from one to one and a half meters in length. To protect against corrosion, steel pipes are coated with heat-resistant enamel. Enamelled pipes for the geyser must be insulated in winter.

- Coaxial chimneys - constitute a structure of two pipes, one in another. Connections are made using jumpers, thanks to which the elements do not touch each other. Through the outer channel air from the street enters the burner. Exhaust gases go out through the central channel. This design allows the outdoor air to be heated when it enters the burner, which increases the efficiency of the system.

- Double circuit - as in the previous case, they consist of two pipes located one inside the other. Elements are separated from each other by thermal insulation made of mineral wool. Due to this warming, no condensate forms inside the system.

For the hood, you can use any of these pipes. The only thing to be borne in mind that the price of materials is different.

Tip! To make the column safer, and also to protect it from children, it should be placed high enough. Best of all, the device is located on the wall under the chimney.

Chimney installation

Installation of the hood should start from the column.

A brief instruction on the implementation of this work is as follows:

- First of all, you need to install a connecting pipe in the wall through which the exhaust will pass. You also need to install a turn that will provide a transition to the outer, vertical part of the structure.

- Then the tube must be connected to the outlet of the column.. It is best to use a corrugated pipe for this purpose, since it is much easier to work with it.

- A chimney should be installed on the outer wall.. The design is assembled by placing the bottom element in the top. Joints must be fixed with clamps.

- For the reliability of the system, it should be fixed with brackets, the step between which should be about two meters.

- After mounting the vertical part, you need to install the tip. In addition, in the lower part of the vertical structure you need to perform a revision window.

- Upon completion of work, be sure to check the traction.. To do this, bring a lit match to the chimney. The light should deviate in the direction of the chimney.

Note! When installing the system, it is necessary to pay attention to the absence of deflections. They should not be throughout the entire length of the structure.

We considered the option of installing an outdoor chimney. In the house, you can also perform an internal system that will bring the products of combustion to the outside through the attic. In this case, the order of work looks almost the same, except that the inlet pipe is installed in the ceiling, and not in the wall.

In this case, it is necessary to additionally make a hole in the roof covering, ensuring the sealing of the passage of the pipe.

Causes of problems

Most often, problems in the system of flue gas emissions arise for the following reasons:

- Incorrectly installed design or in its manufacture used materials of poor quality. For example, during the operation of the column, they can burn out.

- Poor thermal insulation of the structure or lack thereof, which leads to the formation of a large amount of condensate.

- Violation of the integrity of the system.

Tip! If the house already has a fireplace, boiler or other device with an equipped chimney, the exhaust hood can be connected to it. However, it must be borne in mind that no more than two devices are allowed to be connected to one chimney. In addition, when connecting to the heater chimney device should not work simultaneously.

Conclusion

Pipes for gas columns are a means of normal operation of the device, as well as protection against carbon monoxide and gas leakage from the pipeline, in the event of a malfunction of the device. Therefore, when installing the structure, it is necessary to strictly observe all the requirements listed above.

From the video in this article, you can get more information on this topic.