Pipe for the boiler - manufacturing and installation

When installing a heating boiler, an important point is the installation of a chimney, and, regardless of whether the boiler runs on solid fuel or on gas. The safety of the heating system and its efficiency primarily depend on it. In this article, we consider how to make a pipe for the boiler and perform its installation.

Pipe manufacturing

Primary requirements

The presence of the exhaust channel is one of the most important conditions for the use of the boiler. It is necessary for the withdrawal of toxic products of combustion to the outside. It must be said that such a pipe, as a rule, comes complete with a boiler, however, in some cases it may be necessary to make it independently, for example, this may be due to the configuration of the premises.

It is not difficult to manufacture the structure, the most important thing is that it meets certain requirements, which we will consider below:

- Chimney material must be non-combustible..

- The minimum cross section of the chimney should be at least 250x250 mm. The diameter is calculated depending on the area of the boiler chimney;

- The joints of structural elements must be sealed.. Sealing is performed naturally by non-combustible materials.

- If the design consists of several sections, then each upper section should be put on the bottom.

Knowing these rules, it is not difficult to perform the chimney or chimney, the only thing you need to decide on the material for its manufacture.

Materials

Not so long ago, chimneys were mainly made of brick, however, in recent times many other options have appeared. Next, we consider the most common:

| Galvanized pipes | This design is sealed and absolutely fireproof. Most often a galvanized steel exhaust pipe is used for a gas boiler. Its main advantage is durability and low weight. |

| Of steel | The design is strong and fireproof, however, is not durable. As a rule, such a chimney can last 5-7 years. |

| Asbestos Concrete Pipe | The advantage of the design is the low price, however, it is characterized by some drawbacks, including fire hazard. The fact is that this material has the property to quickly accumulate soot on the inner walls, which can ignite. Since the heat resistance of asbestos concrete is very limited, the design may collapse, causing a fire. |

Manufacturing

In fact, the manufacture of the chimney is to prepare pipes, which are subsequently assembled into a single system. Therefore, at this stage it is only necessary to calculate the length of the pipes and cut them. After that, you can proceed to installation.

Pipe installation

Primary requirements

There are a number of important requirements for the installation of chimneys and flues:

- The channel of the chimney should be placed vertically (the maximum deviation is allowed not more than 30 degrees per meter), and should not be narrowed and extended throughout its length.

- The pipe should rise above the ridge of the house, which will prevent air leakage and ensure high-quality smoke discharge. The height depends on the location of the chimney:

- If the roof is flat, the pipe should rise one meter above it;

- When removing the structure from the ridge per meter, the height above it should be at least 0.5 meters.

- When removing a pipe 2-3 meters from the ridge, it can be set flush with it.

- If the roof is adjacent to a higher building, the chimney should rise above its roof.

It should also be borne in mind that the minimum pipe height for a solid fuel or gas boiler is 5 meters.

- In the presence of bends, the length of the horizontal sections should not exceed one meter.

Note! If the chimney is raised more than 1.5 meters above the roof, it must be fastened with braces.

The walkways

All types of chimneys for boilers are divided into two types:

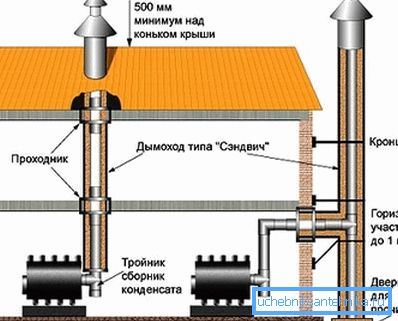

- Outdoor - through the wall or window facing the street and then pass along the outer wall.

- Internal - the main part of the structure is located in the house. Exit to the street through the overlap of the attic and roofing.

In any case, the most difficult moment of installation is the passage device. The fact is that the chimney should not be adjacent to combustible materials (the distance should be 13-25 centimeters), as it is heated to a high temperature, this is especially true for solid fuel boilers. But at the same time, the passage unit must be airtight.

To solve this problem, a duct is usually used, which is also called a feedthrough. This construction can be made of steel or minerite. The space between the box and the pipe is filled with insulating material - it can be mineral wool, expanded clay or even sand.

To seal the passage through the roof using a special design with aprons. Sealing joints is performed using heat-resistant sealant. The wall profile, which is adjacent to the pipe and roof, is usually made of copper, steel or galvanized.

Installation procedure

The installation of the pipe to the heating boiler is performed in the following order:

- The first thing you need to do is markup on the ceiling, in accordance with the size of the passage profile and cut a hole in the ceiling of the desired size.

- Next, a passage box is inserted into the hole.

- Then a pipe is drawn through the connecting pipe and docked with the outlet pipe of the boiler. Thus, the heat pipe of the boiler receives a tight continuation in the form of a chimney system. The joint is sealed with an asbestos cord.

- After that, the installation of the access port in the roofing. For these purposes, a special truss system can be performed.

- At the end of the work, an external pipe is conducted through the connecting pipe and is connected to the pipe of the internal part of the chimney.

Here, perhaps, the entire brief instructions for the installation of the chimney. After its installation, the structure must be insulated and a spark arrester attached to it from above.

Thermal insulation

A mandatory element of the chimney is heat insulation. It prevents the formation of condensation. As the insulating material used mineral wool, which is simply wrapped around the pipe.

The heat insulator must be protected by a casing, it is usually made of galvanized steel.

Tip! In order not to perform thermal insulation of pipes, it is possible to make a chimney of special sandwich pipes, which initially have two walls. Between the walls is a heat insulator.

Major mistakes

More often, all beginners in the construction of boiler tubes do the following mistakes with their own hands:

- Use materials that are not suitable for the chimney (asbestos, aluminum).

- During installation they allow the chimney to come in contact with the ceiling or roof, which leads to charring or even fire of materials (applies to solid fuel boilers).

- Insufficiently sealed pipe connections, which leads to the penetration of smoke into the room. It may be harmful to health.

- Insufficient heat insulation of the structure - even the icing of the gas boiler pipe can be the result of this, especially when the boiler is used from time to time, for example, at the cottage.

Chimney care

In order for the chimney system to effectively cope with the task and serve as long as possible, it is necessary to perform its maintenance from time to time:

- Before each heating season, it is necessary to inspect the structure for rust, cracks or any other defects that may lead to depressurization of the system and penetration of combustion products into the room.

- If the boiler runs on solid fuel, the system must be cleaned every year, otherwise not only its capacity will decrease, but also the likelihood of soot ignition will arise. It is not necessary to perform cleaning mechanically, the procedure can be performed by burning special chemical compounds in the boiler.

Note! Inspection requires not only the chimney, but all the other elements of the system. This will allow time to find and fix the problem. For example, if the boiler is boiling and the pipes are cold, the pump is most likely not working, or the filter is clogged.

Here, perhaps, all the main points of manufacture and installation of pipes for the boiler.

Conclusion

The boiler chimney device requires a responsible approach, as the safety of all residents of the house depends on it. In addition, compliance with all the above standards will make the system more efficient.

With regard to the technical side of the issue, then make the chimney and independently perform its installation under the power of every home master. From the video in this article, you can get more information on this topic.