Pipe inch thread - features and method of cutting

Steel water pipes can be connected not only by welding, it is often used for this thread. Its quality and relationship with the axis of the product is important when installing systems. The use of dies and taps is not always convenient, so most often it is cut with a chisel mounted on a lathe.

General information

Usually it is a helical groove with a constant pitch and cross section. It is applied to the surface of parts of a cylindrical or slightly conical shape, for example, it can be screws, bolts, as well as on the surface of the parts mated to them - nuts (see also the article Pipe for a warm floor: how to choose the optimal type and correctly lay it).

At home, we most often encounter cylindrical pipe threads. In our case, together with the metric, the inch is also successfully applied.

| Metric | Its main characteristics are the pitch, meaning the distance between the depressions or ridges, expressed in mm, and the diameter. |

| Inch |

|

As a result, we have the following form:

- 1 pipe has an outer O33.25 mm;

- 1/2 - 21.25 mm.

Inch cylindrical pipe according to GOST 6357 differs from metric with such nuances:

- ridges are sharper;

- the tops of the threads are slightly rounded.

Most commonly used in everyday life pipes with these types of threads:

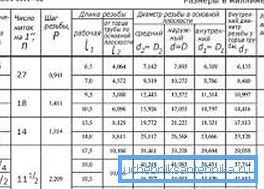

- O 1/2 and 3/4 have 14 threads per inch with a pipe thread pitch of 1.8 mm;

- O 1, 1 1/4, 1 1/2, 2 - 11 threads per 1 with a step of 2.3 mm.

Manufacturing

Below is a process instruction:

- Determine the pitch. To do this, use the thread gauge, a ruler or a caliper will also work.

Tip: you must measure the distance between the tops of the threads of the thread, then divide the result by the number of threads. For an inch thread, you need to count the threads that fit in 1.

It is usually hardly possible to obtain an exact diameter, but the result will be satisfactory.

- Cut the thread, for which they use two methods - with their own hands, as well as with the help of a lathe. In the first case, the operation is accompanied by additional difficulties, which is especially noticeable on products whose diameter is more than 1.

Tip: Experts recommend using a special device (CLEP), consisting of a body and two handles, with adjustable movable combs on it for the manual method. Thanks to them, you can gradually deepen to the desired profile.

You can also use interchangeable combs with incomplete or full profile. The price of such tools is high, so not everyone can get them. Therefore, it should be mentioned about the die or leerku, which can also be cut manually.

During clockwise rotation of the ring holder, it starts to screw onto the threads on the sleeve. The latter is pre-fixed with three bolts.

This device has an undeniable advantage - there is no “stop” in the pipe at the initial stage of cutting. Thanks to the sleeve mounted on the pipe, it is possible to easily make cutting metric and pipe threads.

Tip: You can use threaded bushings of different diameters, which makes it easy to increase the cutting range.

If the cutting will be done by a holder without extension cords or other devices, it usually turns out to be of very low quality. In this case, you can add liners with a length of 100-150 mm, made on a lathe.

Inch threading methods

Manual

If you do not have a nearby lathe or you do not have sufficient skill, you can use hand tools - a tap for internal thread and a die for external.

- Fix the pipe in a vice, insert the tap into the driver, and insert the die into the die holder.

- Depending on what you want to do - insert a tap into the pipe, and put the plate on it.

- Rotate the crank of the knob or the die holder, screw in or screw the device on the product.

Tip: if necessary, the process can be repeated several times until you get the desired result in the depth and height of the profile.

Do not forget also that the cutting inside and outside should be carried out consistently.

Mechanical

- Clamp the pipe in the chuck lathe.

- In the caliper install the necessary cutter.

- Turn on the machine and chamfer in or on the pipe.

- Bring the tool to the inner or outer surface of the product and turn on the “threaded” feed by setting the caliper speed in advance.

You can also use a tap and die on a lathe, fixing them in the front or back of the headstock. Experts recommend still using the cutter, since with sufficient qualification of a turner the result will be much better.

Conclusion

The use of threads makes it possible to connect steel pipes without the use of a welding machine. Thanks to this, it is possible to create quick disconnects, speeding up work and making a minimum of effort.

The video in this article will help you find additional information on this topic.