Pipe laying: how to independently install engineering

Most modern pipelines, ranging from plumbing and sewage inside, ending with the main channels to the septic tank, are made from polymer parts. For the normal operation of these engineering networks, it is important not only the choice of material, but also the proper laying of pipes. The detailed instruction given below is devoted to this process.

Independent arrangement of sewage

Excavation

For the arrangement of sewage systems, as a rule, special plastic pipes with an orange or brown color are used.

Laying polypropylene pipes with their hands begins with digging a trench. This stage, despite its apparent simplicity, must be approached carefully and responsibly, since the efficiency of the entire drainage network depends on it.

It is advisable to follow these rules:

- The bottom of the trench should be 30-40 centimeters below the level of soil freezing. As a rule, in central Russia it is 2.6-3 meters. In the south, polyethylene pipes can be laid at a depth of about 1.5 meters. In any case, it is necessary to deepen the details by not less than 50 cm and in these cases, take measures to insulate them.

- At points where physical impact on pipes in the soil is possible, be sure to use specialized double-layer corrugated pipes with increased strength..

- All parts are connected using specially designed fittings.. Rubber linings are already built in them for pipes which provide the necessary tightness of joints.

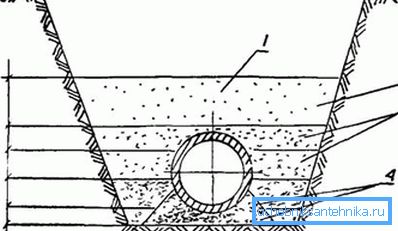

- The trench width should provide normal access to the drain system.. Usually for products with a diameter of 110 mm prepare a ditch about 60 cm wide.

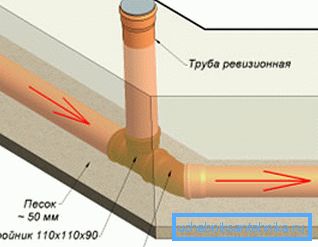

- Laying PND pipe in the ground is carried out with a slight bias. It should be about 1-2 cm per linear meter of sewage. With a smaller value, the waste can form a cork, with a larger one, the walls will not self-clean off the plaque.

- The bottom of the trench should be filled with a layer of gravel and sand about 15 cm thick and lightly tamped. Near the manholes and at the junction with the outlet pipe of the internal sewer network, the gravel is tamped down more tightly in order to avoid shifts in the soil and violation of the integrity of the pipeline.

Tip! At the joints and points of installation of shaped parts in the pillow, pit should be made, otherwise the pipe axis will deviate from the horizontal, which can cause blockages.

Pipeline installation

Laying plumbing pipes in a trench does not cause difficulties, it is enough just to follow some tips:

- Polymer parts should be positioned so that the bell looks in the direction of the drain well or septic tank (in the direction of water flow). Before joining, it is necessary to thoroughly clean the edges from debris, dust and soil particles. Then the smooth end of the pipe is lubricated with silicone sealant and inserted into the socket.

Note! Not all varieties of polymer products have sockets. For example, the laying of metal pipes with their own hands by using compression or press fittings.

- The compensation gap (as in the manufacture of domestic sewage) is not necessary. Separate elements should enter each other against the stop.

- It is desirable that the external drain sewer system does not have turns. If this is impossible to achieve, you need to use special taps with small angles of rotation. In such places it is necessary to equip manholes.

- If the length of the pipeline exceeds 20 meters, it is necessary to provide special inspection holes and, accordingly, wells. The distance between them should not be more than 15 meters.

Warming and backfilling with soil

The cost of laying pipes made of polypropylene or other type of plastic depends on the length of the engineering network and the volume of earthworks. However, it is not necessary to save on digging a trench, since insufficient penetration can lead to the freezing of the pipe during the winter period and the need for its additional warming.

In any case, to protect the sewer from the cold need to exit the foundation of the house. For this purpose, various types of heaters are used: mineral fiber, polyethylene foam, and many others. Remember that the use of certain types of thermal insulation materials may require additional protection from water.

Before backfilling a trench, make sure that the drainage network is operational. Pressed soil can serve as backfill material, but stones and hard parts that can damage plastic can be removed from it.

The pit should be filled with layers from 5 to 10 cm thick with intermediate tamping. In this case, the filling can be compacted only along the edges of the pipeline, in no case from above.

Given that the earth will subsequently shrink, it is advisable to make a mound about 20-30 cm above the trench.

Alternative way to lay an underground pipeline

At present, pipe laying by the HDD method (horizontal directional drilling) is becoming increasingly common, which allows you to mount engineering networks without digging trenches.

This method is simply irreplaceable in the following cases:

- laying under the highway without opening the roadway and blocking the traffic flow;

- installation of new engineering networks without destruction of the existing ones;

- installation of communications under green areas and decorative elements;

- laying without the need to violate the integrity of the soil layer.

In addition, the considered construction method is distinguished by a rather low price. After all, there is no need to dig a trench, and then backfill and repair work.

Features of installation of the gas system

Pipeline

In contrast to the systems of transportation of clean water and the discharge and disposal of used gas, the laying of a gas pipe in a private house must be done according to special rules.

Let us dwell on this in more detail:

- Gas pipe can only be brought into the house through the wall. Building codes prohibited the arrangement of gas pipelines in the foundations. At the same time, it should pass through a steel sleeve, the edges of which protrude at least 3 cm from the wall material. The gap between the structures of the house and the sleeve should be patched with tar tar or some elastic material.

- The gas pipeline should be laid inside the premises only by the open method. The installation of pipes into wall gates is possible only if they are subsequently closed with easily removable non-hermetic shields or panels.

- Indoor gas pipe must be painted with water-repellent paint to protect parts from corrosion.

- Incoming pipeline should immediately fall into non-residential premises. If this is not possible, wiring, including transit, can be carried out through the living rooms.

- The gas pipeline must not be connected using threaded couplings for pipes. In residential areas it is forbidden to equip shut-off valves.

- When docking the pipeline with consumers should provide two types of locking devices:

- on a gas pipe that cuts off the entire gas device as a whole;

- in the device (turns off each burner separately in the absence of a flame).

Most often, modern gas appliances are already equipped with appropriate safety devices, so you just need to install a valve on the pipeline itself.

- Welding is used to connect the various parts of the domestic gas pipeline into one system. Threads and flanges can only be used to install valves, metering devices, pressure regulators, and so on.

Gas appliances

When placing cookers, water heaters and other gas appliances, certain requirements should also be followed:

- the height of the ceilings in the room is at least 2.2 meters;

- floor space of at least 15 sq.m .;

- if the kitchen is combined with a dining room or living room, the area of the room should be at least 30 square meters;

- the room must be ventilated;

- Be sure to provide free access to valves.

Conclusion

Regardless of whether the pipes are being laid in the bathroom or the installation of an external sewer network, all the installation rules described above should be carefully and scrupulously observed. Otherwise, the drain or plumbing system may not work properly, which would entail the need for costly repairs. More details about this can be found in the video in this article.