Pipe pp: a wide range of applications of polypropylene

In order to save financial costs, as well as reduce the complexity of installation today widely used pipe PP for heating, water supply and sanitation. This material has good performance, and the range of products from it is wide enough so that we can find parts for almost any system.

In our article we will talk about the varieties of this material, and also pay attention to the features of its installation.

General material characteristics

Main varieties

Heating, plumbing and sewer pipes PP are made from polypropylene - a process polymer that is characterized by high corrosion resistance, considerable strength and acceptable elasticity. On the modern market there are products from many manufacturers, however, the leadership in this segment is firmly kept by Turkish (slightly lower price with quite acceptable quality) and Czech (slightly more expensive) brands.

If we talk about varieties, then first of all you need to mention these:

- Pipe PN20. The most versatile design that is used in cold and hot water supply systems, for the manufacture of pneumatic piping, nozzles, etc. The walls do not contain a reinforcing belt, while the product can withstand pressures up to 2 MPa.

- Model PN 25, reinforced with fiberglass. It has a three-layer structure, due to which it can withstand more pressure (up to 2.5 MPa). It has low rates of thermal expansion, can work with coolant up to +95 0WITH.

- Model PN 25 ALLUMINIUM It is an analogue of the previous version, but for the reinforcement is not fiberglass, but thin aluminum foil. It has a low coefficient of linear expansion.

Note! Products from the PN 25 series do not require stripping when connecting pipes, which significantly speeds up installation, especially if you plan to do all the work yourself.

- The sizes of PP pipes with internal reinforcement are quite diverse.A: the minimum diameter is 20 mm and the maximum diameter is 63 or 100 mm, depending on the model.

- PN20 (Kalde) Pipe Series Also available with reinforcement - fiberglass or aluminum. Unlike previous versions, the reinforcing layer is outside, which explains the need for stripping before installation. For this reason, polypropylene pipes of the 20th series are gradually disappearing from the market.

- Sewer pipes. Available from less resistant plastic, since most of them are not designed for use in pressure systems. Usually they have a shaped construction (with a socket and a sealing ring at one end). The most common diameters are 32, 50, 75, 110 and 160 mm.

Note! All products usually come with a full set of connecting fittings for pipes, as well as adapters for adjacent sections.

Naturally, here is not a complete list of models that make up the range. Of unnamed attention deserves, for example, corrugated pipe PPL, which is used for hidden cabling, as well as products for laying a warm floor.

Advantages in operation

There are many advantages to polypropylene pipes:

- Firstly, the material itself has sufficient mechanical strength and high corrosion resistance for use in most systems. This explains the durability of pipelines.

- Secondly, the parts are quite easy to fit the size, processed and connected. At the same time, the reliability of the installation is quite high: for example, welding the PP pipes with your own hands allows you to form a one-piece joint that can withstand slightly less pressure than the pipe itself.

- Thirdly, when in contact with water, the material does not change its chemical composition, which is very important when using PP pipes in water supply. And from the point of view of ecology, polypropylene is quite safe (naturally, provided it is effectively utilized).

However, these products are not universal. For example, pipe systems for PP (steam-water heaters), pipelines of thermal installations, etc. it is better to do it from metal.

Connection methods

Fitting

Instructions for the connection of products depends on the conditions in which they will be used. As a rule, non-pressure sewer systems are mounted using flange parts, while water mains and heating systems require the use of special fittings for welding.

The sequence of assembly of the flange connection is as follows:

- The pipe is customized in size by cutting it with a saw. Then we carefully clean the cut edge with a file, and process the butt with a special tool, forming a bevel.

- In the shaped part of the second pipe install rubber sealing cuff.

Note! Most models are sold with seals already installed, so we can only check their status.

- Apply silicone grease to both connected parts, then insert the nozzle into the socket to the stop.

- Having fixed the position, we extend the pipe approximately 1 cm, forming a gap to compensate for thermal expansion.

- After completion of the work, we fix the structure to the wall or floor with a clamp to eliminate the deformation of the joint.

The main disadvantages of this technique are only two:

- First, elastic rubber rings are deformed over time and require replacement.

- Secondly, with increasing pressure in the system at the site of contact with a high probability of leakage.

However, for the sewage of such a safety margin is enough.

Welding

Welding of PP pipes is carried out differently:

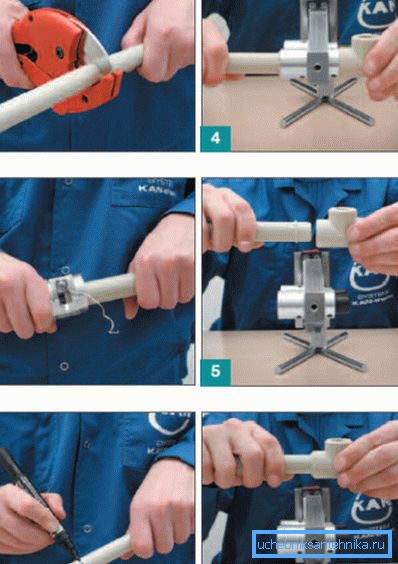

- First, prepare the edge of the pipe for installation. To melt the material and form a high-quality monolithic seam, it is necessary to remove the reinforcing layer from it - aluminum foil or fiberglass. To do this, clean the pipe with a knife or a special tool.

- On the soldering iron for PP pipes, we install nozzles whose diameter corresponds to the cross section of the pipe and fitting itself.

- On the nozzles we put on the parts to be joined, which we warm up until the polypropylene melts. It is important not to overdo the soldering iron on, so the work should strictly adhere to the manufacturer's recommendations on the exposure time and heating level for a pipe with a particular wall thickness.

- We remove the heated parts from the soldering iron and insert the pipe into the fitting all the way.

Tip! This should be done without rotation, since any displacement of elements will deteriorate the reliability of installation.

- Fix the connection until the plastic is polymerized. Up to this point, it is advisable not to expose the place of contact to any loads.

The advantage of this method of installation is that the fusion of polymers ensures the formation of a monolithic node capable of withstanding any deformation and load.

Conclusion

The sewer and water pipes of software differ in high universality and convenience in assembly. The simplicity of processing the technological polymer and the possibility of using welding greatly facilitates the arrangement of communications, so that not even the most experienced master can cope with this task.

A more detailed description of the pipes, as well as the features of their use, can be found on the video in this article.