Pipe ppm and its features

The main problem of the steel pipeline is the adverse effects of the environment, which leads to corrosion. To solve this problem, manufacturers produce pipes in polystyrene (PPM) insulation. In this article we will look at what properties the MRP pipe has, and examine the scope of this product.

Features of the pipe PPM

General information

Penopolimermineralnaya shell for pipes is made of foamed polymer, to which is added mineral fillers, which can be used as:

- Ash;

- Sand;

- Slags.

Thanks to these additives, the rigidity of the shell and strength are increased, which makes it immune to mechanical stress. In addition, the peculiarity of the polyurethane foam is waterproof, combined with vapor permeability.

Manufacturers put this material on the pipe from the outside.

Moreover, the shell contains three layers:

- Corrosion-resistant inner layer - thickness 5 - 10 mm.

- Directly heat insulation.

- Protective outer layer, which has a high density. Its thickness is 10 - 15 mm.

As for the pipe itself, the insulation can be applied to products that meet the requirements of GOST 8731, 10704, 8733 and 20295. That is, these can be welded or seamless pipes with a diameter of 32 to 820 mm and a length of up to 12 m.

Note! The length of the uninsulated ends is 150 mm with a diameter of up to 219 mm, inclusive, and 200 mm with a diameter of 273 - 1020 mm.

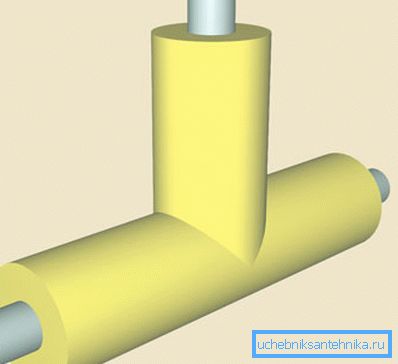

In addition to pipes, they cover with insulation:

- Transitions;

- Elbows;

- Tees for connecting pipes, as well as some other shaped elements.

Pipes in PPM insulation are widely used during the installation of heating mains, as well as hot water supply pipelines, where it is important to preserve thermal energy during the transportation of the coolant. Moreover, these pipes were even included in SNiP 41-02-03 as a possible option when laying a heating network with a coolant temperature not exceeding 140 degrees Celsius.

All types of gaskets are allowed:

- Underground channelless;

- Underground channel;

- Overground.

It should be noted that this product was developed by domestic experts, who took into account climatic and some other features. Therefore, we can say that this product is adapted for use in our country.

Insulation characteristics

The main technical characteristics of PPM pipe insulation are presented below:

| Thermal conductivity | 0.043 W / m ° C |

| Water absorption by weight for 30 days | 6% |

| Adhesion tube | 0.4 MPa |

| Heat resistance | 150 ° C |

| Compressive strength | 1.2 MPa |

| Bulk weight | 280-300 kg / m3 |

Merits

Penopolimermineralnaya shell has many advantages over other types of heat insulators for heat networks. This is due not only to the properties of the materials used, but also to the design features, thanks to which it meets the basic requirements of operation in heating networks.

In particular, the following points can be highlighted:

- The material is not "cracked" during operation.. In other words, during the entire life cycle, the thickness of the heat insulator remains unchanged.

- Water absorption penopolimermineralnoy shell is much lower than the same indicator of mineral wool.

- PPM insulation has a closed cell structure, thereby reliably protects the steel pipeline from corrosion (subject to the use of additional anti-corrosion protection). In addition, there is no need to cover it with your own hands with a plastic or steel sheath.

- The coefficient of thermal conductivity of this insulation is several times lower than that of wet mineral wool.. As a result, heat loss through penopolymermineral isolation is much less than through mineral wool. Therefore, in real conditions of PPM, the coating is much more effective than insulation for pipes based on mineral wool.

- Lower price, than on such a common type of insulation like PUF.

- Coating increases the life of the pipeline, which is more than 30 years, and also reduces the cost of its maintenance.

- Reduces the likelihood of accidents.

- In case of leakage, there is no need to change the coating., as it dries and at the same time keeps the properties.

- Does not require installation of the DCS system.

disadvantages

Since there are no ideal materials, pipes with this insulation also have some drawbacks, the most serious of which are:

- Large weight, resulting in their transportation is associated with additional costs. In addition, instructions for their installation involves the use of lifting equipment.

- PPM has a higher coefficient of heat loss than PPU, since the thermal conductivity of polymer-polymeric insulation is 10-20 percent more.

- Thermal insulation of PPM is not completely sealed, so the pipeline must be further processed with an anticorrosive agent.

Note! The maximum pressure in the pipeline, made of polyurethane foam pipes, should not exceed 2.5 MPa.

Conclusion

PPU insulation for pipes has a number of advantages over other types of heat insulators, in particular, it can be used for open systems without additional housings. But the main thing - it allows you to save heat energy of the coolant with minimal losses, which is the main task of any insulation.

From the video in this article, you can get more information on this topic.