Pipe pprc: familiarity with the products + application

Interestingly, the abbreviation PPRS (Pollution Prevention Resource Center) stands for Resource Center for the Prevention of Environmental Pollution, which is quite suitable for polypropylene pipe (PPR - English, PP - Russian), which is also called ecoplast.

Such pipelines are mainly used for hot and cold water mains, as well as indoor heating circuits. In addition, PPR can be reinforced and integral, which determines its purpose taking into account the temperature mode of operation and these are the types that will be discussed below, where you will also see the video in this article.

Meet the pipes

Species

- All polypropylene pipes in addition to its cross section are divided by the ability of the walls to withstand the pressure and temperature of the flowing fluid., and for this there is the designation: PN with numbers that indicate density.

- PN10 is designed to supply cold ox up to 20? C (short-term temperature 45? C), where the operating pressure does not exceed 1 MPa (10 kg / cm2). The external section PN10 can be from 20 mm to 110 mm, while the internal diameter is from 16.2 to 90 mm. The thickness of the walls, which is in the range of 0 t 1.9 mm to 10 mm, also depends on the cross section of the pipe.

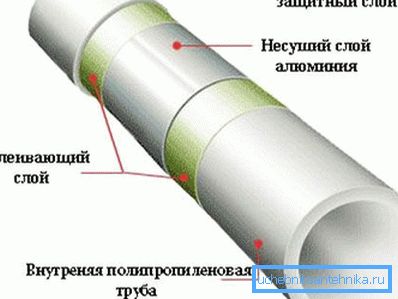

- PN20 plumbing equipment is called a universal pipe, as it can be used for both cold and hot water, where constant heating does not exceed 80? C, which is quite acceptable not only for hot water supply, but also for heating. The walls of this PPR can withstand up to 2 MPa (20 kg / cm2) and most often reinforced with aluminum foil. The external section PN20 can be from 20 mm to 110 mm, while the internal diameter is from 10.6 mm to 73.2 mm, and the wall thickness depends on the section, which ranges from 16 mm to 18.4 mm.

- PN25 says that products are reinforced with aluminum foil or fiberglass, and also indicates that the constant temperature of the coolant can reach 95? C, which, however, happens very rarely. Such pipes are usually used for centralized heating and their price is the highest among analogues. The walls of PN25 are designed for a constant pressure of 2.5 MPa (20 kg / cm2) with a thickness of 4 mm to 13.3 mm, outer diameter from 21.2 mm to 77.9 mm, inner diameter from 13.2 mm to 50 mm.

Note. In PN25, the reinforcing layer is not located in the middle, but closer to the top (the walls of the inner tube are thicker) and this is a hindrance during welding, since the inner diameter of the coupling will coincide with the reinforcement cross section. Therefore, the foil needs to be removed and the instruction recommends doing this with the help of the shaver, as shown in the photo above.

What are the advantages

Of course, the main advantage is the high technical characteristics of the PPRC pipe and, first of all, it is the duration of the operational period, where the minimum warranty is 50 years, and some manufacturers double this period to 100 years!

In addition, polypropylene complies with the European WHO standards, since no deposits and corrosion are formed inside the pipe, and this also means that the passage of water does not decrease with time.

PPR is not afraid:

- sudden changes in temperature and pressure;

- has a very low thermal conductivity (a big plus for the DHW and the heating circuit);

- and also, it is a good noise attenuator - the supplied liquid almost does not make noise.

If we compare polypropylene with metal, the installation of the PP pipeline is carried out about 10 times faster, thanks to the unique technology of welding with an electric soldering iron. The low mass of the pipes allows installation alone, and the corrosion-resistant surface almost completely negates the external maintenance of the pipeline.

Assembly work

In order for the welding joint to turn out to be homogeneous, you need to hold the pipe and fitting on the hot tip of the soldering iron for a certain period of time, which you can see in the table above. Thus, the most common diameter PPR (20 mm) is heated by a soldering iron at a temperature of 270-280? C for 5-6 seconds. Then, both elements are abruptly released from the nozzle, joined and hold for another 2-3 seconds (more is possible) to fix the soldering.

It is very important that the pipe go into the fitting for a certain distance, if it goes shallowly, that the joint may break, and if it is too deep, the end of the pipe will abut the wall of the fitting and flatten out, reducing the throughput. The table also indicates the depth of landing when soldering, for example, for the same 20-mm PPR this distance is from 1.4 mm to 1.7 mm, and for a larger cross-section the soldering is deeper.

Note. All soldering irons are designed for a maximum temperature of 300-350? C, but do not work at maximum limits. So, for welding a pipeline at room temperature and above, 270-280? C is sufficient, and more hot modes are needed in cases where welding takes place outdoors (wind) or at lower temperatures.

The soldering of the polypropylene pipeline is much more convenient to carry out in blocks, rather than one element at a time. For example, if you need to reach the boiler from the cold water main, then along the way there will be tie-ins to the toilet, bathtub and sink, therefore, it is better to solder all tees for decoupling beforehand, and then install the finished unit. The same operations are appropriate for hot pipes for hot water supply or heating.

Conclusion

All welding work with polypropylene pipes you can do your own hands, without resorting to the services of a specialist, if you have a soldering iron for PPR and theoretical knowledge of the installation of such pipelines. This is also one of the advantages of PP - for its installation it is not necessary to have a lot of practice and special training behind you - everything is done easily and quickly, but, of course, subject to the requirements mentioned above. Good luck!