Pipe supports - types and specifications

Get out and look at the pipelines that surround you. It is hard not to notice that they are necessarily supported by some supports above the ground or on the ground. Due to this, it is possible to connect the elements together in a system that has a greater length.

Today the article will be devoted to this particular topic, where we will look at fixed and sliding supports for pipes in PU foam insulation.

Theoretical knowledge

When laying such networks, it is customary to give a special role to compounds that may lose their reliability, which will immediately be transferred to the whole structure if you do not take care of its rigid fixation.

Select the main factors affecting the strength of the system:

- climate;

- mass of the structure;

- external vibrations.

At the same time, supports make it possible to reduce their negative impact.

Usually they can be found in the organization of systems:

- oil and gas transportation;

- technological value;

- at nuclear and thermal power plants;

- for engineering designs.

Installation Features

In the development of such structures take into account the standard diameters of pipelines, which according to GOST can be 18-1620 mm. The supports are usually made of metal, and installation often causes difficulties.

Advice: it is better to provide such work to specialists. Otherwise, unpleasant consequences may occur due to incorrect calculation of structural elements that are constantly under heavy load from the system and the fluid circulating in it.

Installation technology can be different, but there are two main ones:

- using clamps;

- using welding equipment.

In any case, the type of metal for the supports depends on its characteristics, and the main thing is its ability to withstand high loads.

Tip: between structures, the distance is calculated based on the diameter of the pipe, the substance transported through it, the installation technology.

Kinds

There are two main types of supports for pipelines - movable (sliding) and fixed. When choosing, take into account their working conditions and system operation.

| Stationary |

|

| Movable |

The last two are used for systems that can deform due to temperature differences. |

Classification

The supports can also be classified on the basis of their design features and installation technology.

There are such designs:

- Body welded, the advantage of which is simple installation and affordable price. They are used for steel structures, differ in a variety of technological solutions.

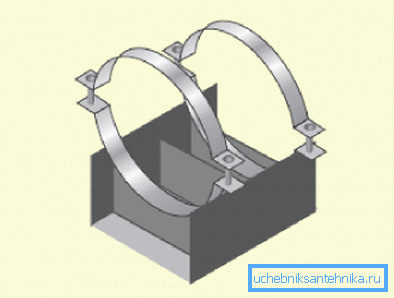

- Body clamps can have a round and flat yoke (used only for steel). The first in addition to steel can be used for structures of pre-insulated type. This type also includes drag constructions where there are no stiffeners.

- Frameless or conventional hose clamps. Fixed versions are connected to the base due to welding, movable provide free movement. They are also called clamp hops.

- Steeply curved bends that are mounted under the bend of the desired design. Used for fastening various equipment.

- Shield required for reliable mounting of the vertical sections, they are installed by welding. Quite often they are mounted with the passage of structures through the wall. They are referred to the fixed type of products.

Except for the last option, all other supports can be mobile and fixed.

Polypropylene Pipe Support

To work with such products it is necessary to use special devices, which can be:

- ordinary (standard);

- with clip;

- with a strap;

- double.

In fact, industrial enterprises are ready to offer customers a wide range of similar products that will satisfy basic needs.

Such a support is a clamp or ring on a stand made of gray or white polypropylene. May be closed or open type. Basically, fixed support for polypropylene pipes is used to hold them in the manufacture of heating systems, supply of cold-water and hot-water supply. The support on walls from various materials is established, a design strong and durable.

Instructions for use are simple - first, they are fixed with their hands to the surface with a screw or something similar, then a pipe is installed into it. According to the rules, they should be placed through each meter or according to technological need, which directly depends on the temperature of the working environment.

Supports different types and diameters. Versions with a clip or a strap hold the pipeline more reliably, double-type allows you to fix two pipes of the same diameter.

Conclusion

The article considered various supports for pipes that can be movable and fixed. With their help, it is possible not only to reduce the dependence of systems on external influence, but also to facilitate installation (find out here how to build a chimney for a gas boiler).

The video in this article will help you find additional information on this topic.