Pipe thread: types and characteristics

Most often, installation of collapsible types of pipelines is carried out using a threaded connection. For convenience, all threads used in pipes are standardized. Next, we consider their main characteristics, types, methods of application and sizing.

Types

Specifications

Everyone knows what a thread looks like - it is a sequence of helical grooves that have a constant pitch and section. It can be applied to the surface of a cylindrical or conical shape.

As for pipes, cutting can be used in products for various purposes, to ensure collapsible installation of the pipeline. Most often it is found in household water supply and heating systems.

Its main characteristics are the following indicators:

- Location;

- Unit size measurement;

- Direction;

- Thread Forming Profile;

- Number of visits.

It should be noted that the threaded connection of pipes is a rather isolated group of standards, which is regulated according to GOST 6357-81.

Note! The connection of pipelines with a cross section of more than 6 inches should be performed by welding.

Inch

The inch carving is applied on metal pipes, and also metal and plastic pipe fitting of folding type. According to GOST, its main characteristics are pitch and diameter.

Moreover, this parameter can be understood as:

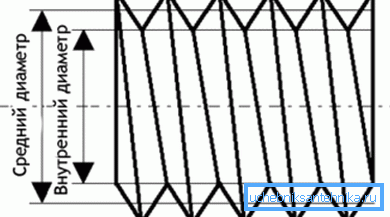

- Outer diameter - the distance between the upper opposite points located on the tops of the ridges.

- Inner - the distance between the lower opposite points located on the depressions of the grooves.

The difference in these parameters is determined by the profile height.

Step, as it is not difficult to guess - this is the distance between adjacent turns. This parameter is always the same for the entire threaded section. All dimensions in this case are in inches.

The table below shows pipe thread sizes in mm:

| Diameter in inches | Outer diameter of pipe threads in millimeters | Step |

| 2 | 59,616 | 2.309 |

| 1 3/4 | 53,748 | |

| 1 1/2 | 47,805 | |

| 1 3/8 | 44,325 | |

| 1 1/4 | 41,912 | |

| 1 1/8 | 37,898 | |

| one | 33,250 |

Note! Other dimensions include GOST 6357-81 pipe threads.

In everyday life, pipes with the following types of cutting are most often used:

- With a step of 14 threads per inch:

- diameter 3/4 ?;

- 1/2 ?.

- diameter 1 1 - 4;

- one?;

- 2 ?;

- 1 1/2?

Metric

The main characteristics of the metric cut, the same as the inch - the diameter and the distance between the turns. But, in this case, how does the metric thread differ from the pipe thread?

In fact, there are very few differences, the main ones are in the following points:

- Comb profile shape. The inch profile is more “sharp”.

- Metric dimensions are in millimeters. However, for convenience, you can convert pipe threads in mm.

- A pitch in an inch design is considered not in mm, but in threads - the number of grooves that fit on an inch measuring line. For example, in standard water pipes there are two versions of the “step”:

- on 11 threads (2.31 mm);

- on 14 threads - (1.8 mm).

For the rest, pipe and metric threads do not differ.

Note! The size of the tube inches is different from the usual. One such inch is 3.33 centimeters, not 2.54.

Sizing

Metric thread and pipe is measured by the same tools:

- Caliber;

- Calipers;

- Combs.

Therefore, the instruction for measuring these parameters for the inch and for the metric design looks the same. Also, as a caliber, you can use a union or a coupling with known parameters.

Measuring the distance between the coils is quite simple - you need to screw the bolt into the part, or screw the nut on it. If the process of screwing does not cause difficulties, and at the same time the bolt or nut sits tightly, then the distance of the turns on the pipe corresponds to this parameter on the bolt.

The thread meter works even easier. This tool contains measuring plates that resemble a set of nail files. These nail files are applied to the section with coils. If the profile matches, then the cut value corresponds to the value indicated on the tool plate.

Note! With a caliper and a micrometer, only the outer diameter can be measured. Therefore, the best tool for this purpose is the gauge and gauge.

Application Methods

Today there are two ways of cutting:

- Mechanical;

- The hands, with the help of dies and tap.

The technology of manual cutting is as follows:

- First of all, it is necessary to fix the pipe in a vice.

- Next, the tap must be inserted into the knocker, and a die for pipe threads in the die holder.

- Then the plate should be put on the pipe, and the tap inserted into it. After that, turn the tool handles.

- If necessary, the cutting operation must be repeated several times to cut through the pipe body to the desired depth, ensuring a uniform profile height.

Of course, the mechanical method of cutting, i.e. on a lathe, provides higher quality. Therefore, it has to apply threads in the workshop, besides the price for similar services of a turner is, as a rule, quite affordable.

Conclusion

Threaded connection is very popular in domestic pipelines. However, it should be borne in mind that the threaded section on the pipes may have a variety of parameters that you need to know in order to select compatible fittings and other parts for the pipeline.

Similar information can be obtained from tables in reference books or measured independently. From the video in this article, you can get more information on this topic.