Pipe tubing: scope and features of the product

The tubing tubing in accordance with GOST 633 80, is designed for pumping gas, oil, liquids from wells, as well as for transporting substances for various purposes. In addition, the products are successfully used for maintenance of fields and repair and technical works.

Types of products

Manufacturers offer several high-tech products.

What manufacturers produce

- Products with smooth ends. These are highly hermetic counterparts. For the manufacture of the base and couplings for pipes is steel with a marking strength: K, E, L, M.

- Products with threaded ends planted out. At one end of the threaded coupling. In this case, the steel grade is used for tubing pipes: D, K, E, L, or M. For increased tightness and corrosion resistance, the thread is covered with a special lubricant.

- Smooth-free pipes designated by NCB. Keep tightness at elevated pressure up to 50 MPa. Outside ends ensure a reliable and durable connection. Strengthen the effect located behind the thread with a smaller diameter tapered seals. The material is equipped with a trapezoidal type of thread.

- Coupling analogues with NCI marking. Designed for pressure up to 50 MPa, and the connection corresponds to the strength of the pipe itself up to 90%. They are also available with trapezoidal thread.

- Aluminum Alloy Pump Products. This production of tubing tubing offers materials resistant to hydrogen sulfide corrosion.

Note! This is beneficial in the absence of the need to use anti-corrosion inhibitors. There are other advantages of aluminum. Thus, a metal with a small weight has a strength 2.5 times higher than steel analogues. This allows you to significantly lengthen the highway.

- Products with special coating. It protects the surface not only from corrosion, but also prevents the deposition of gypsum salts and paraffin. The instruction recommends applying the product where frequent repairs are problematic and inappropriate. Inside the pipe is covered with varnishes, enamels or liquid glass.

- Fiberglass pipes. They are used for injection PPS wells, as well as for gas-lift, utilization systems and production ESP wells.

Design features

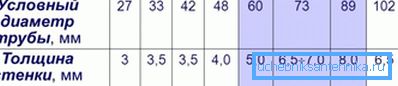

- The smooth tubing tube 73 and 89 (the numbers indicate the diameter in millimeters) is completed with a triangular (10 threads / inch) or trapezoidal (6 threads / inch) thread.

- Smooth counterparts with a cross section of 60 and 114 mm, as well as couplings for them, are available with a triangular-shaped thread.

- Manufacturers also produce hot-rolled seamless products.

- According to the GOST for tubing pipes, before threading the product is inspected by a magnetic induction device.

Requirements for transportation and operation

For high-quality operation of products for a period prescribed by the standards, certain rules should be followed.

- Even if you have purchased pipes bu NKT, it is not allowed to dump them from the body. For loading or unloading a crane is required.

Note! To transport the material by fiber, without special equipment, as well as to allow sagging and bending is absolutely not recommended. In this case, one cannot do without a specialized pipe truck.

- Do not stack products directly on the storage area. Under the tubing tubing 73 b y, etc., be sure to enclose the bars of wood. Only in this case will they be protected from sagging and dirt. At the same time, threading rings are screwed onto the threads.

- Before using the pipe, it is necessary to inspect the quality and absence of defects. To do this, they are alternately passed through a special template. Its diameter is 2-3 mm less than the internal diameter of the pipe, and its length is up to 100 mm. Until the release of the template, the lower end of the product must be held.

- If you do all the work with your own hands, be sure to clean the nipples and the threads on the couplings with a metal brush before screwing the pipes. Then the thread is lubricated with a special lubricant.

- It is strictly forbidden to use a hammer or sledgehammer to facilitate unscrewing couplings.

Sequence of use

There are quite strict rules not only storage, but also the use of this product.

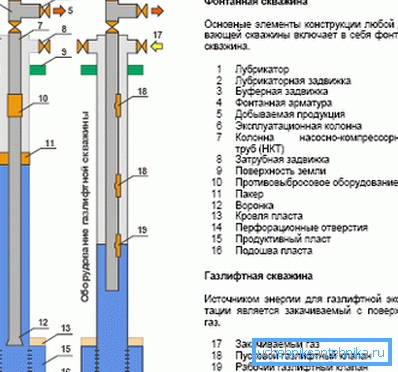

- The tubing is inserted into the finished well only after the injected casing is cemented. For successful input as well as fixation, columns use parkers.

- Products are distinguished not only by price, but also by types. Depending on the type of pumped fluid and pumping method, a certain type of pipe is used.

- If simultaneous production from one well is planned, the installation of columns with different degrees of productivity is allowed. Such wells are called double.

- The tubing is periodically removed for replacement or repair. This distinguishes them from casing, fixed in the well cement. After the scheduled repair, even the used products of the 89 do not lose their working capacity, and it retains the inherent characteristics.

- It is recommended to install multifunctional tubing at facilities with undesirable idle system during maintenance or repair work.

Compliance Standards

Products must comply with the following parameters.

- Ensuring optimal flow.

- Surface flow pressure should be maximized.

- Pipes tubing for the intake of liquid substances must be resistant to corrosion throughout the operational life.

- A standard for tensile strength is provided.

- Material is provided with resistance to mechanical stress.

- The pipe must be provided with the necessary resistance to erosion.

Conclusion

Even if the site uses a tubing pipe 60 b y, as well as 73 and 89, you can be calm for ensuring a decent quality of the system. The manufacturer guarantees efficiency in compliance with the norms and requirements. More information in the video in this article, where the topic is deployed clearly.